RegionRat

Gold $$ Contributor

It's impossible to over heat the case body. 500-700F for less than a second does zero annealing. 750F for 1 minute does zero softening of the brass.Ya didn't say what kind.

My bench source, 2 gas torches, I'd watch for a little red and turn it down just below that.

The idea is to get the the neck and shoulder up to temp fast as possible so the heat won't go down the case. It's hard to do with one torch, imo.

Now i have an amp

I'm going to have to disagree with this statement. 750f for 1 minute would not be goodIt's impossible to over heat the case body. 500-700F for less than a second does zero annealing. 750F for 1 minute does zero softening of the brass.

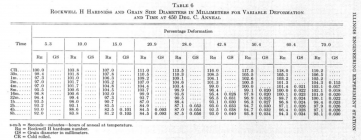

Opinions are not facts. The below chart was created by the metallurgy dept. at Illinois University. I have many other quality annealing charts made in metallurgy labs. The data is from furnace annealed cold rolled coupons held at a constant 450C (842F) temp. for the time and cold work indicated.I'm going to have to disagree with this statement. 750f for 1 minute would not be good

I guess I'm Just confused, here you sayIt's impossible to over heat the case body. 500-700F for less than a second does zero annealing. 750F for 1 minute does zero softening of the brass.

but in post 40 you say, "Perfect brass annealing would make the brass unsafe to use"It's impossible to over heat the case body.

I just ordered an annealer but have never annealed and know nothing about it. The annealer has a timer and I been have searching trying to find out when my brass reaches the proper temperature.

https://ia904700.us.archive.org/21/...tion Making-NRA by G. Frost-(1990) _text.pdfOpinions are not facts. The below chart was created by the metallurgy dept. at Illinois University. I have many other quality annealing charts made in metallurgy labs. The data is from furnace annealed cold rolled coupons held at a constant 450C (842F) temp. for the time and cold work indicated.

1 full minute in the furnace at a constant 450C (842F) with 20.9% starting cold work the hardness only drops about 3 hardness units. This is about the 5th. time I put this chart on the website. All chart data is 450C. Time is total time in the furnace.

15% cold work for 30 seconds at 450C (842F) the hardness drops less than 1 hardness unit.

View attachment 1549135

coupons

I didn't post it in the proper format.I guess I'm Just confused, here you say

but in post 40 you say, "Perfect brass annealing would make the brass unsafe to use"

I'm just a simple minded person and I use a bench source and do what others have mentioned, start in the dark and get the dull red glow. lucky for me I do enough wild catting that I always have case rejects to test with. a simple pair of plyers and a squish tells me if I have achieved what I am after. no charts for me. If you want to subject your bass to 750f for 1 minute and then shoot it, that's up to you, I wouldn't do that not ever, not one time in my life.

I never suggested annealing for 1 minute. The data points out that flash annealing hardness must be much less change if not much occurs at 1 minute at temp. If you cannot over anneal in 1 minute at 842F you cannot over anneal by flash annealing for a fraction of a second at that temp.I guess I'm Just confused, here you say

but in post 40 you say, "Perfect brass annealing would make the brass unsafe to use"

I'm just a simple minded person and I use a bench source and do what others have mentioned, start in the dark and get the dull red glow. lucky for me I do enough wild catting that I always have case rejects to test with. a simple pair of plyers and a squish tells me if I have achieved what I am after. no charts for me. If you want to subject your bass to 750f for 1 minute and then shoot it, that's up to you, I wouldn't do that not ever, not one time in my life.