Background:

Ruger AR-556 Model# 08539

Using Dillon 550, Dillon 223 3 die set, Dillon 223 case gauge. I have bee reloading, mostly Pistol for +20yr. from the Dillon 550 and some rifle (30-30 30-06) from a single stage press, (Sold those Rifles long time ago when i got into Pistol shooting), but just started loading 223 from the Dillon.

I am loading from New or once fired, (My factory rounds ) at (24gr. of 2230 powder for +3K FPS with a 55gr. JHP. Over all length of 2.2575” ( Specs. 2.260”) (matching the Winchester 556 Factory rounds)

Cases have been cleaned and trimmed to specs.

Also using NEW “Starline Remington Brass 223”.

What happened:

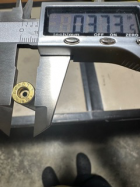

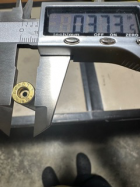

Had two rounds that on loading from mag., Jammed that required a Gun Smith to extract. Yes they were live rounds stuck entering the chamber. (bullet wasn’t stuck, just the case seating in the chamber) On bough occurrences, the Rifle had just been cleaned before going to the range and +20 rounds fired before problem. Yes the Bolt Carrier group was disassembled, cleaned and inspected.The stuck rounds (necks) were somewhat deformed from the removal but did manage to check the size at the head. Checking the cases for sizing (I think I may have had some early rounds that I picked up from the range by mistake) and found that the diameter at the case head was 0.376” (which is spec). Even my case gauge passed them. I measured a factory round ( Winchester .556 55gr JHP) and they checked out to be 0.3735”.

Today:

Gun smith couldn’t find anything with the AR. Has sent it back to Ruger for Warranty and checkout. Should be back in a couple of weeks, I HOPE.

I have checked EVERY hand-load round for case specs, overall length, and bullet diameter with caliper and case gauge. I did find a few that the head size was at the 0.376” and tried to resize them. They didn’t want to resize in the Dillon die (tended to stick and didn’t want to have one stuck in my die so discarded them)

So now all of my handholds are at 0.3735” which matches the Winchester 556 55gr. JHP and some bulk “Factory” rounds that I have.

My Question is:

Was it the Rifle? The Jams occurred on different days after each being cleared by the gun Smith. He cleaned the Rifle and I did a followup cleaning / inspection before shooting again. Don’t think it was dirt in the chamber or Mags as was firing from bench and Mags were loaded at home.

Were these just 2 bad reloads (even though they went through the checks and resizing dies) ?

Do I readjust my checks and dies to the Listed Specs. (0.376”) or just stay with the (0.375”) that Factory rounds measure at?

Thanks for any Suggestions or comments.

KenK

NEW “Starline Remington Brass 223

My Once fired and reload with the “Starline Remington Brass 223

Winchester 556 55 Gr. Factory

Ruger AR-556 Model# 08539

Using Dillon 550, Dillon 223 3 die set, Dillon 223 case gauge. I have bee reloading, mostly Pistol for +20yr. from the Dillon 550 and some rifle (30-30 30-06) from a single stage press, (Sold those Rifles long time ago when i got into Pistol shooting), but just started loading 223 from the Dillon.

I am loading from New or once fired, (My factory rounds ) at (24gr. of 2230 powder for +3K FPS with a 55gr. JHP. Over all length of 2.2575” ( Specs. 2.260”) (matching the Winchester 556 Factory rounds)

Cases have been cleaned and trimmed to specs.

Also using NEW “Starline Remington Brass 223”.

What happened:

Had two rounds that on loading from mag., Jammed that required a Gun Smith to extract. Yes they were live rounds stuck entering the chamber. (bullet wasn’t stuck, just the case seating in the chamber) On bough occurrences, the Rifle had just been cleaned before going to the range and +20 rounds fired before problem. Yes the Bolt Carrier group was disassembled, cleaned and inspected.The stuck rounds (necks) were somewhat deformed from the removal but did manage to check the size at the head. Checking the cases for sizing (I think I may have had some early rounds that I picked up from the range by mistake) and found that the diameter at the case head was 0.376” (which is spec). Even my case gauge passed them. I measured a factory round ( Winchester .556 55gr JHP) and they checked out to be 0.3735”.

Today:

Gun smith couldn’t find anything with the AR. Has sent it back to Ruger for Warranty and checkout. Should be back in a couple of weeks, I HOPE.

I have checked EVERY hand-load round for case specs, overall length, and bullet diameter with caliper and case gauge. I did find a few that the head size was at the 0.376” and tried to resize them. They didn’t want to resize in the Dillon die (tended to stick and didn’t want to have one stuck in my die so discarded them)

So now all of my handholds are at 0.3735” which matches the Winchester 556 55gr. JHP and some bulk “Factory” rounds that I have.

My Question is:

Was it the Rifle? The Jams occurred on different days after each being cleared by the gun Smith. He cleaned the Rifle and I did a followup cleaning / inspection before shooting again. Don’t think it was dirt in the chamber or Mags as was firing from bench and Mags were loaded at home.

Were these just 2 bad reloads (even though they went through the checks and resizing dies) ?

Do I readjust my checks and dies to the Listed Specs. (0.376”) or just stay with the (0.375”) that Factory rounds measure at?

Thanks for any Suggestions or comments.

KenK

NEW “Starline Remington Brass 223

My Once fired and reload with the “Starline Remington Brass 223

Winchester 556 55 Gr. Factory