I am interested in seeing how you guys are setting up these short barreled rifles for threading the muzzle and keeping the bore aligned for suppressor use. I am getting more and more people wanting these 20" and shorter barrels. Currently, the distance from my outboard spider to the face of my spider chuck is 20". If I can get the barrel off I just set it up in the Viper rest and get it done as I normally would no big deal. The problem I am having is I just had a guy bring in a Howa 1500 that has a factory 20" sporter barrel on it. Try as I might I can't get that damn barrel off so I am interested in seeing how others would handle this project or if you would just tell the guy he is out of luck.

You need to make (or buy) a fixture for trueing receivers, bolts and short barrels.

Just a length of heavy wall pipe with 2 or 3 sets of spider screws that allow you to dial in short barrels just like inboard/outboard spiders on the spindle.

Deltronic gage pin in the bore to dial in the muzzle end for threading. Depending on the length of your headstock/spindle I would leave the receiver spun on the barrel- no need to remove it unless the headstock is too long.

You need to make (or buy) a fixture for trueing receivers, bolts and short barrels.

Just a length of heavy wall pipe with 2 or 3 sets of spider screws that allow you to dial in short barrels just like inboard/outboard spiders on the spindle.

Deltronic gage pin in the bore to dial in the muzzle end for threading.

I have one, the Viper. The problem is with the receiver attached, and the recoil lug built into the receiver on the Howa it don't fit. This is what I have, and normally what I would use.

Are you ready to take your chambering skills to the next level? Finally, a barrel alignment fixture for precision chambering of barrels that are too short to be held by an outboard spider on the lathe spindle. Also solves the problem of lathes with long headstocks where standard length barrels...

www.grizzly.com

The last Howa 1500 we broke loose we had an internal action wrench with a 24" breaker bar on it and an external wrench. Had to bump the external with a hammer. It was a little snug.

Paul H

I’m in a similar position

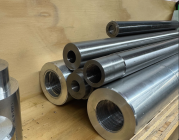

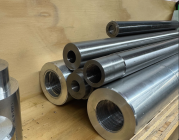

I make a barrel extension that threads onto the tenon so I can use my rear spider.

An action fixture could certainly be an alternative but my lathe is too small for that probably.

I have through of an action fixture that directly engaged the taper on my spindle nose, that’s possible feasible for my application.

Another convenient but expensive option is the true bore alignment system (TBAS).

Need a tool make a tool:

Another convenient but expensive option is the true bore alignment system (TBAS).

Need a tool make a tool:

View attachment 1723668

That I can do and understand. But that still doesn't help me if I can't get the barrel off. I have plenty of other work to do. I am leaning toward just telling the guy he is out of luck. I have already spent enough time on it when I could have been doing something else.

I have extensions, like Aaron just posted. I use those but if I have to I’ll use my Viper, it works as advertised but I don’t like indicating and setting up in it. It’s a last resort thing.

I’ve been considering adding a smaller headstock lathe. Presently, I’m just not doing any muzzle threading that’s not a rifle I built. But I have a day job and don’t have to take jobs to keep the lights and heat on.

I assume the action body wont fit through your headstock?

I assume the action body wont fit through your headstock?

Correct.

Pass. One of the hardest things to learn is to just say no to work that wont make money because of the time.

I have extensions, like Aaron just posted. I use those but if I have to I’ll use my Viper, it works as advertised but I don’t like indicating and setting up in it. It’s a last resort thing.

I’ve been considering adding a smaller headstock lathe. Presently, I’m just not doing any muzzle threading that’s not a rifle I built. But I have a day job and don’t have to take jobs to keep the lights and heat on.

This is the exact same situation I am in. I have been looking at Lathes as well but I just can't justify the cost. It would take a hell of a lot of threading jobs to pay for it.

This probably wont be the last time you get a difficult to remove action. Talk to customer about potentially marring or scarring that might happen because factory barrels are all but welded on. Buy/build the tools you need to crack the action off.

If I’m doing one where the action stays on and the barrel is too short to span the headstock I do it in the steady rest. Use a mandrel in the action and put the mandrel in the chuck. There’s a lot more involved than that simple explanation but it’s simple machine work. Howa Mini’s are a common one. Made a mandrel to align and drive them.

Make a little spider to run in steady rest then drive action with a 4 jaw. Pad with thick brass/aluminum shim stock to be easy on finish.

Make a little spider to run in steady rest then drive action with a 4 jaw. Pad with thick brass/aluminum shim stock to be easy on finish.

Or slip a mandrel into the receiver and drive it that way while running the barrel in the steady. WH

Or slip a mandrel into the receiver and drive it that way while running the barrel in the steady. WH

This^^^^^^

Or slip a mandrel into the receiver and drive it that way while running the barrel in the steady. WH

Yup.

Contrary to popular opinion, neither the lathe nor the barrel will self-destruct when the steady rest is used...

Steady rest always ruins the finish on the barrel especially a blued one.