You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Induction brass annealer redux

- Thread starter Gina1

- Start date

Switching the power supply on is more than enough to 'kickstart' the ZVS board. There's also nothing wrong with leaving it on all the time if you can control consistently how long a case is in the coil. The problem doesn't reside there.

If you want to control the operation of the ZVS board (for 'working time'), don't use a relay to switch the 48V supply when all you need to do is ground/unground the ZVS board's FET gates. This way you are switching a light load and needn't worry about blowing the relay switching high current and voltage.

(I agree that getting the ammeter working would be useful in the absence of other mechanisms for seeing what's going on. It doesn't sound like it wired correctly.)

If you want to control the operation of the ZVS board (for 'working time'), don't use a relay to switch the 48V supply when all you need to do is ground/unground the ZVS board's FET gates. This way you are switching a light load and needn't worry about blowing the relay switching high current and voltage.

(I agree that getting the ammeter working would be useful in the absence of other mechanisms for seeing what's going on. It doesn't sound like it wired correctly.)

Sorry for the late reply. My power supply is a 36V 1000W supply. I have it set at 34V and the amp draw is in the high teens, 17-18.What power supply do you use and how much current it draws? Thank you!

Just got the replacement PSU.

Everything works now. The cheap chinese PSU was the culprit.

Everything works now. The cheap chinese PSU was the culprit.

itchyTF

Gold $$ Contributor

What PS did you get?Just got the replacement PSU.

Everything works now. The cheap chinese PSU was the culprit.

Meanwell SE-600-48What PS did you get?

I currently have it turned it down to 40v.

I de-soldered the voltage regulating potentiometer and with 3 wires I installed 10 K ohms potentiometer on the front panel for easy access.Meanwell SE-600-48

I currently have it turned it down to 40v.

Glad that you are at final stages.

Thanks!I de-soldered the voltage regulating potentiometer and with 3 wires I installed 10 K ohms potentiometer on the front panel for easy access.

Glad that you are at final stages.

Still brainstorming where/how to mount this PSU as it is so much larger.

Ideally you want the shortest, most powerful blast of power (V x I) possible.

I'm not sure that is correct. For fine tuning - in order to stop the annealing (observing the thempilaqe) at the right temperature - you do not need the steepest temperature curve. As long as the PS can deliver annealing power to a specific caliber - regulating the amount of the power is beneficial. You remember that I maintain 1000F (regulating the amount of power by pulsing) at the case for 1.88 sec to satisfy the formula. So controlling the power by voltage or else is good.

We may be splitting hairs, but what I mean is you want to heat the relevant area to the requisite temp quickly. If you heat it slowly the heat will conduct away from the relevant part of the case to where it is doing no good. I agree there is some requisite time for which the relevant area of the case needs to be held at target temp (depending on that temp) but ideally things ought to happen faster than slower (to reduce the loss from conduction).

Incidentally, I was reading again yesterday the Ambrell sheet on ammunition brass annealing from which I had noted previously the frequency of operation used. It mentions a temperature of 1250F which would allow an even shorter 'anneal time period'.

(Likely the load presented by the case will also determine the power. If the load can draw more power, the current will possibly increase to offset the lower voltage assuming the PSU current isn't being limited also.)

I'm back (finally) to looking the code required to follow in your and @VenatusDominus good footsteps and implementing the flame sensor I have installed. (Calculating time with a PIC is a little more 'interesting' when there is no access to a regular clock.) Can you point me to the source of your 1.9 sec at 1000F calculation?

Incidentally, I was reading again yesterday the Ambrell sheet on ammunition brass annealing from which I had noted previously the frequency of operation used. It mentions a temperature of 1250F which would allow an even shorter 'anneal time period'.

(Likely the load presented by the case will also determine the power. If the load can draw more power, the current will possibly increase to offset the lower voltage assuming the PSU current isn't being limited also.)

I'm back (finally) to looking the code required to follow in your and @VenatusDominus good footsteps and implementing the flame sensor I have installed. (Calculating time with a PIC is a little more 'interesting' when there is no access to a regular clock.) Can you point me to the source of your 1.9 sec at 1000F calculation?

The following formula is used to calculate the time and temp to anneal brass:We may be splitting hairs, but what I mean is you want to heat the relevant area to the requisite temp quickly. If you heat it slowly the heat will conduct away from the relevant part of the case to where it is doing no good. I agree there is some requisite time for which the relevant area of the case needs to be held at target temp (depending on that temp) but ideally things ought to happen faster than slower (to reduce the loss from conduction).

Incidentally, I was reading again yesterday the Ambrell sheet on ammunition brass annealing from which I had noted previously the frequency of operation used. It mentions a temperature of 1250F which would allow an even shorter 'anneal time period'.

(Likely the load presented by the case will also determine the power. If the load can draw more power, the current will possibly increase to offset the lower voltage assuming the PSU current isn't being limited also.)

I'm back (finally) to looking the code required to follow in your and @VenatusDominus good footsteps and implementing the flame sensor I have installed. (Calculating time with a PIC is a little more 'interesting' when there is no access to a regular clock.) Can you point me to the source of your 1.9 sec at 1000F calculation?

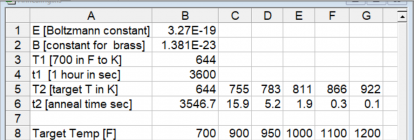

B=1.38065x10^-23 (Boltzmann constant)

E=0.327x10^-18 (constant for the material, in this case brass)

T1 in Kelvin = 644 (700 F)

t1 in sec = 3600 (1hour)

T2 in Kelvin = target temp

t2 in sec = time to anneal

t2=t1*exp^(-E/B*(1/T1 - 1/T2))

This is easy to plug into Excel and if you pick 810.9 K (1000 F) for your target temp you will anneal in 1.88 seconds. Note that brass starts to glow between 950 F and 1050 F depending on the exact composition. Using 900 F changes the required time to 16.1 seconds.

Thanks. Source of the formula?

While the discussion made sense, it's a shame that he made no effort to source, explain or derive the formula. (Definitely not worth the subscription fee to watch it.)

FYI I've attached the Ambrell paper I have mentioned a few times here. They used 113kHz and 1250F. In the video relating to the paper (see below) they mentioned a time of 3 secs which of course includes the time it takes to get to 1250F. It is interesting to plug in 1250F into this guy's formula and see that the time required is de minimus, 3 hundredths of a second. Touch 1250F and you're done...

FYI I've attached the Ambrell paper I have mentioned a few times here. They used 113kHz and 1250F. In the video relating to the paper (see below) they mentioned a time of 3 secs which of course includes the time it takes to get to 1250F. It is interesting to plug in 1250F into this guy's formula and see that the time required is de minimus, 3 hundredths of a second. Touch 1250F and you're done...

Attachments

Last edited:

The Metal Engineer makes a lot of sense. His formula (may be he is the author or comes from his text books) reflects the obvious fact (as you said "make sense") that brass annealing is time-temperature dependent. If Ambrell Corporation has any scientific formulations of the brass annealing , we all be grateful to look into it and implemented in our builds. From the attached material I saw just another annealer.While the discussion made sense, it's a shame that he made no effort to source, explain or derive the formula. (Definitely not worth the subscription fee to watch it.)

"brass annealing is time-temperature dependent."

Yes, that's obvious with even cursory thought. Very, very little time at some temperature and longer at a lower temperature. The question has always been "how much time at what temperature?" This has typically been considered in the form of 'touching' a target temp, ie trying to understand what the "very, very little" time end of the scale is.

"The Metal Engineer"

This we are left to take on faith. Unfortunately he doesn't provide any credentials in the video. Again, it's a shame he doesn't provide a little background on himself and his metallurgical skills. (The rest of the video could easily have been a quarter of its length to accommodate this.) Perhaps he discussed his background more in another video?

"His formula (may be he is the author or comes from his text books)"

That's my point. Unfortunately we have no idea where it came from and he doesn't make an attempt to explain it. As a result it's disappointing in this regard.

Ambrell Corporation make, amongst many other things, custom commercial annealing machines, including those for ammunition casings. They come with a lot of credibility. Two good things come from the little case study they posted on their website. The frequency their demonstration annealer operated at, 113kHz (something that's been debated here before) and their target temperature, 1250F, each stated in their pdf.

About the only defense of Reese's formula I've found is from this Ambrell case study. Plug in their target temp of 1250F from their PDF and you need only hit it for a tiny fraction of a second (which seems to be supported by their video).

Anyone working with a simpler GinaErik implementation would likely do well to use 1200F or even 1300F Tempilaq as their target. (Given the vagaries of deciphering color changes in Tempilaq 1200F or 1300F is likely accurate enough as attempting greater accuracy is likely spurious.) It also supports the idea that you want to deliver a great deal of power very quickly to the area of interest.

Yes, that's obvious with even cursory thought. Very, very little time at some temperature and longer at a lower temperature. The question has always been "how much time at what temperature?" This has typically been considered in the form of 'touching' a target temp, ie trying to understand what the "very, very little" time end of the scale is.

"The Metal Engineer"

This we are left to take on faith. Unfortunately he doesn't provide any credentials in the video. Again, it's a shame he doesn't provide a little background on himself and his metallurgical skills. (The rest of the video could easily have been a quarter of its length to accommodate this.) Perhaps he discussed his background more in another video?

"His formula (may be he is the author or comes from his text books)"

That's my point. Unfortunately we have no idea where it came from and he doesn't make an attempt to explain it. As a result it's disappointing in this regard.

Ambrell Corporation make, amongst many other things, custom commercial annealing machines, including those for ammunition casings. They come with a lot of credibility. Two good things come from the little case study they posted on their website. The frequency their demonstration annealer operated at, 113kHz (something that's been debated here before) and their target temperature, 1250F, each stated in their pdf.

About the only defense of Reese's formula I've found is from this Ambrell case study. Plug in their target temp of 1250F from their PDF and you need only hit it for a tiny fraction of a second (which seems to be supported by their video).

Anyone working with a simpler GinaErik implementation would likely do well to use 1200F or even 1300F Tempilaq as their target. (Given the vagaries of deciphering color changes in Tempilaq 1200F or 1300F is likely accurate enough as attempting greater accuracy is likely spurious.) It also supports the idea that you want to deliver a great deal of power very quickly to the area of interest.

This is a great scientific article on annealing brass:

vacaero.com

vacaero.com

Deformation and Annealing of Cartridge Brass

Copper and its alloys are among the most malleable metals and alloys in existence. Cartridge brass, Cu – 30% Zn, has been used for many years to produce cartridge cases for ammunition due to its superior cold forming characteristics. This article shows the microstructure and hardness of...

Thanks. There's a lot of busted links for this article out there. Finally one that works. (I also came across an article done recently as someone's Phd, IIRC, and which was done with the assistance of Norma. Unfortunately, again, the anneal times used were very long.)

Check out the hardness vs temp for 30 minutes chart. Plug in the 900F point (where the curve begins to 'flatten') into Reese's formula as T1. Implies brass needs a lot of annealing if its been cold-worked...

Check out the hardness vs temp for 30 minutes chart. Plug in the 900F point (where the curve begins to 'flatten') into Reese's formula as T1. Implies brass needs a lot of annealing if its been cold-worked...

Check out the hardness vs temp for 30 minutes chart. Plug in the 900F point (where the curve begins to 'flatten') into Reese's formula as T1. Implies brass needs a lot of annealing if its been cold-worked...

Reese formula gives 16 minutes. It is not clear if Mr. Voort has taken pictures at 15-th or 20-th etc minutes to show the annealing progress. Most likely the sample is being already fully annealed in the half time. If this is the case the formula is on target.

Also see at 1200 F - 0.1 sec annealing time - actually Ambrell from your video indirectly confirms the formula.

From a practical point view - the time difference [~3 sec between 950 and 1000 F ] gives us ample opportunity to observe the tempilaq and determine anneal timing or to calibrate a flame sensor.

The formula is very complex and it reflects all the curves that Mr Reese has shown us. As you have said before, about the curves " it make sense", I believe the formula is correct and quite useful for our hobby.

Fill free to ask Mr Reese for his credentials (no need to say "Again, it's a shame he doesn't provide a little background on himself and his metallurgical skills.") or the origination of the formula. I admire the person who put this formula on paper,

Similar threads

- Replies

- 74

- Views

- 47,364

- Replies

- 0

- Views

- 1,576

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.