Isnt that just a scroll chuck not a set-tru? Im in the same boat needing a set tru. I like the gator as of right now

I put a Gator on my TBAS. They are nice chucks, but the first one had the bolt holes for the 2pc jaws drilled and tapped crooked. I sent a pic to lathe-chucks.com and they quickly responded and rectified the situation. Since they didn't have another cast body one in stock, they immediately shipped out an upgraded steel body chuck. The only thing they asked was that I pay return shipping on the old one after I received the replacement.

I have no complaints with the new one.

I made one years ago from a regular scroll chuck and back plate when I was working in a tool and die shop. I don't remember the details but I remember it took a ton of time, even with all the right tools at my disposal. I'm thinking 10 hours machining time for some reason. It's been a long time ago. I thought about doing it again but I had a print to work from then and that's a lot of time and money to scrap something out vs just paying the $800 plus a semi finished back plate.

How big of a chuck you need?

M.Ezell

Gold $$ Contributor

How big of a chuck you need?

I'd just like to be able to chamber in it so, 1.350-1.500ish id. It's a small lathe but has a 1.410 spindle ID. So, the right 6" would work, I'm thinking...but I wouldn't be averse to a little bigger chuck.

M.Ezell

Gold $$ Contributor

How big of a chuck you need?

Wouldn't mind one for my 13x40 Jet with a d1-4 too but am thinking for the heavy 10 at the moment.

I'd just like to be able to chamber in it so, 1.350-1.500ish id. It's a small lathe but has a 1.410 spindle ID. So, the right 6" would work, I'm thinking...but I wouldn't be averse to a little bigger chuck.

I think i want a 6. Im running an 8 right now but its so heavy. I just dont know what id be missing besides a little smoother finish

M.Ezell

Gold $$ Contributor

I think i want a 6. Im running an 8 right now but its so heavy. I just dont know what id be missing besides a little smoother finish

I have no problem with that difference in weight. Would prefer a little too big than the other way around...same reason. It threads nice with a light 6" 4 jaw but I'd like a little more weight, which the set true will be.

I do mostly 308 chambers... so in my last order of reamers I got a JGS spiral core drill (rougher)

Not seeing these on the JGS website.

Not seeing these on the JGS website.

Give em a call or get our man

@Ray Gross to get you one

I put a Gator on my TBAS. They are nice chucks, but the first one had the bolt holes for the 2pc jaws drilled and tapped crooked. I sent a pic to lathe-chucks.com and they quickly responded and rectified the situation. Since they didn't have another cast body one in stock, they immediately shipped out an upgraded steel body chuck. The only thing they asked was that I pay return shipping on the old one after I received the replacement.

I have no complaints with the new one.

Did they install the Gator on the TBAS or you did?

Wouldn't mind one for my 13x40 Jet with a d1-4 too but am thinking for the heavy 10 at the moment.

I'm running a 6" Buck Set-Tru on my Jet, and have been for years. !3 x 40 is what I chamber on , and it's too small for 99% of the other machining I do, and the CNCs are 10 station "turret" lathes, not really conductive for chambering. I've got a 6" PBA 4 jaw for the Jet that I use, too. They (6" chucks) don't take an overhead to c/o like the bigger lathe does.

Not seeing these on the JGS website.

They're in the catalog.

Give em a call or get our man

@Ray Gross to get you one

We have roughers.

Isnt that just a scroll chuck not a set-tru? Im in the same boat needing a set tru. I like the gator as of right now

Just a scroll chuck. It runs out a thou. I bought it as a just in case thing. First time I've used it in almost 15 years.

You got the piloted core drills?

You got the piloted core drills?

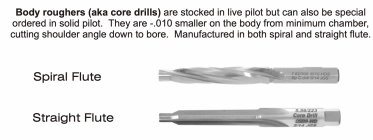

They call the core drills roughers in the catalog. They also say the live pilot are stocked but solid can be ordered.

special

They call the core drills roughers in the catalog. They also say the live pilot are stocked but solid can be ordered.

special

View attachment 1410030

Very good

You got the piloted core drills?

We (Manson) only make the roughers, no core drills. It would be nice to be able to offer that and a few other things, but for now we're just trying to keep up with orders for the stuff we do make

I think i want a 6. Im running an 8 right now but its so heavy. I just dont know what id be missing besides a little smoother finish

Bruce had us get a Bison Set True for the HJ-1100. It is a nice chuck. I think it's an 8". Bruce put a test bar in it and he was impressed.

I was having our new guy dial in a piece of a barrel before he cut the tenon and threaded it, and I needed to figure how the chuck worked first. It was pretty easy. I got him close and let him finish.

It's backwards from a spider--you tighten one of the adjuster screws and it pulls the adjustment, but that was easy to remember. We had the lock screws snug but not overly tight. Bruce later said that's how he ran his and never had an issue with it coming loose.

Ours is a three jaw and it's on a dedicated barrel chambering machine. I asked Bruce why he didn't have us get a six jaw. Now this is where an argument is going to occur, if I am remembering correctly.

He said because barrels are not perfectly round in the OD, a six-jaw almost never grips evenly with all six jaws. He said it's usually only four. He said that with a three-jaw, all three jaws will engage evenly.

I pointed out that we were going to have to put aluminum strips over the jaws for carbon wrapped barrels. He agreed.

I do like the chuck. It is very smooth. Wondering if I should get a D1-4 6 or 8" for my 1340GT at home, even though I did just build an inboard spider which I like very much. I'll know soon how well it holds its adjustment. That said, I am about 50/50 in having to tweak my spider when I check it between threading and chambering.

Bruce had us get a Bison Set True for the HJ-1100. It is a nice chuck. I think it's an 8". Bruce put a test bar in it and he was impressed.

I was having our new guy dial in a piece of a barrel before he cut the tenon and threaded it, and I needed to figure how the chuck worked first. It was pretty easy. I got him close and let him finish.

It's backwards from a spider--you tighten one of the adjuster screws and it pulls the adjustment, but that was easy to remember. We had the lock screws snug but not overly tight. Bruce later said that's how he ran his and never had an issue with it coming loose.

Ours is a three jaw and it's on a dedicated barrel chambering machine. I asked Bruce why he didn't have us get a six jaw. Now this is where an argument is going to occur, if I am remembering correctly.

He said because barrels are not perfectly round in the OD, a six-jaw almost never grips evenly with all six jaws. He said it's usually only four. He said that with a three-jaw, all three jaws will engage evenly.

I pointed out that we were going to have to put aluminum strips over the jaws for carbon wrapped barrels. He agreed.

I do like the chuck. It is very smooth. Wondering if I should get a D1-4 6 or 8" for my 1340GT at home, even though I did just build an inboard spider which I like very much. I'll know soon how well it holds its adjustment. That said, I am about 50/50 in having to tweak my spider when I check it between threading and chambering.

Put your indicator on the bottom and try that

Did they install the Gator on the TBAS or you did?

I ordered them separately and installed the Gator myself.