Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

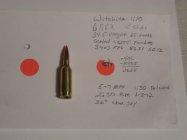

Freebore Mug Shots 6BRX

- Thread starter tclaunch

- Start date

Re: Freebore Mug Shots 6BRX More Mug Shots

Tim,

If a shooter already had such a chamber or reamer, wouldn't a correctly dimensioned sizing die accomplish the same thing? I got my .284 Shehane die from Warner Tool and it perfectly sizes both body and shoulder .001".

http://www.warner-tool.com/reloading.htm

tclaunch said:I will also let you know there has been a run of bad advise from tool a maker to use a .470" diameter at the .200" line above the base or boltface. I urge anyone to add .001" to this to help eliminate the horrible "click" at the top of extraction of the bolt handle. Incorporate a .471" @.200" .Freebore diameter can get too tight and a .2436" is my preference.

Tim,

If a shooter already had such a chamber or reamer, wouldn't a correctly dimensioned sizing die accomplish the same thing? I got my .284 Shehane die from Warner Tool and it perfectly sizes both body and shoulder .001".

http://www.warner-tool.com/reloading.htm

Re: Freebore Mug Shots 6BRX More Mug Shots

Agreed, if your project was in the planning stages. Warner's die also has a few other advantages but it is not inexpensive.

Agreed, if your project was in the planning stages. Warner's die also has a few other advantages but it is not inexpensive.

Re: Freebore Mug Shots 6BRX More Mug Shots

How are you loading them? Jam, jump, touch? How much?

How are you loading them? Jam, jump, touch? How much?

bozo699

Gold $$ Contributor

Re: Freebore Mug Shots 6BRX More Mug Shots

Tim,

Here was what I came up with today, I had a little time so I loaded 6 rounds for my 1:10 6BRX Witchita ground hog gun. I chambered it with the same reamer I use on my long range rifles, it is pt&g .104 free bore I have about .090 of bearing surface in the case and I am touching the lands. It was a little windy but it was clear out so I thought I would go for it. the other picture shows my 6brx with 107SMK and the other is the 65 V-Max so I would agree with you much more free bore is really needed for 105's - 115's then .104

I hope it is calm in the a.m I am going to try for a group in the teens.

Wayne.

Tim,

Here was what I came up with today, I had a little time so I loaded 6 rounds for my 1:10 6BRX Witchita ground hog gun. I chambered it with the same reamer I use on my long range rifles, it is pt&g .104 free bore I have about .090 of bearing surface in the case and I am touching the lands. It was a little windy but it was clear out so I thought I would go for it. the other picture shows my 6brx with 107SMK and the other is the 65 V-Max so I would agree with you much more free bore is really needed for 105's - 115's then .104

I hope it is calm in the a.m I am going to try for a group in the teens.

Wayne.

Attachments

Re: Freebore Mug Shots 6BRX More Mug Shots

Good luck with it Wayne, go for it!!

For anyone interested in the reamer print of the .140" BRX, I just ordered my replacement today and was sent my print. You are welcome to try this out and am hopeful it does for you what it has recently been doing for me. I left the freebore diameter at .2435". I did change the diameter @.200"

Good luck with it Wayne, go for it!!

For anyone interested in the reamer print of the .140" BRX, I just ordered my replacement today and was sent my print. You are welcome to try this out and am hopeful it does for you what it has recently been doing for me. I left the freebore diameter at .2435". I did change the diameter @.200"

Tim,

How did I miss that print you posted.. I've read so many BRX post researching new rifle my head is gonna explode..

That's Great

Thanks

Ron

How did I miss that print you posted.. I've read so many BRX post researching new rifle my head is gonna explode..

That's Great

Thanks

Ron

This print was a replacement for a PT&G reamer that the smith I was using at the time, refused to ever use again. Said it cut very poorly. I since bought my lathe, and find that reamer cuts fantastic. I just run my lathe slow while chambering, and have learned how to burnish the cutting edges with an Arkansas hardstone.Ha, I been back to when you first got on Tim. Lots of info from way back...

Guessing this is the reamer you used?

I actually dont chamber anymore straight BRX`s for me personally, and have purchased a new reamer with an .080" long version of the BRX, that is .080" long over the parent BR case instead of the .100" long BRX. This gives a longer neck on the BRX case which is better to my liking.

Last edited:

I recall that, glad it is working out for you!!!I think I bought that particular reamer from Tim a couple years ago. And it shoots very well!

I actually dont chamber anymore straight BRX`s for me personally, and have purchased a new reamer with an .080" long version of the BRX, that is .080" long over the parent BR case instead of the .100" long BRX. This gives a longer neck on the BRX case which is better to my liking.

Tim forgive me if im prying too much and apologize if i sound too new at this..

And thanks again for sharing

i noticed your 6brx claunch print shows a 1.1902" body.. which is almost .120" longer than 6BR body of 1.071... so now you shortened the body .020"ish to give longer neck..

correct me if in wrong but now your using a body similar to std +.100 over 6BR eg 1.171"ish.. or are .020 shorter yet and have a body of 1.151"

do you still like .471" at the .200" line/ reason i ask is new Lapua measures .468" at the .200" then my Redding FL die with my crude tool measures .466" with my vernier ( not correct method ).. im worried if i blow out to .471" after few firings without dies to match larger at .200" im gonna work brass too much possibly be trimming a often..

Ron

Similar threads

- Replies

- 44

- Views

- 4,608

- Replies

- 13

- Views

- 1,406

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.