I would think with the leverage in a Rockchucker press that it would be hard to get accurate measurements. I would even think the speed at which you pull the handle would change the pounds of force. You are talking alot of leverage. Much better getting a 21st Century or K&M arbor press with the guages. Matt

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Force guage for bullet seating

- Thread starter Jennb

- Start date

I would think with the leverage in a Rockchucker press that it would be hard to get accurate measurements. I would even think the speed at which you pull the handle would change the pounds of force. You are talking alot of leverage. Much better getting a 21st Century or K&M arbor press with the guages. Matt

you would need to get a robotic right arm calibrated to be able to get a consistent steady pull on the lever every single time applying the same exact pressure at the exact same speed or the readings will vary no matter what press and pressure sensing setup you are using. The accuracy of any test can only be as accurate as the least accurate component of the test procedure, which in the case of an arbor press would the person pulling the handle which is why I have not ordered a hydro press long ago.

edit -

Arbor press of choice - $100

4 channel data logger - $200 https://www.onsetcomp.com/products/data-loggers/ux120-006m

AC gear motor with a reverse ??

Pulley, cable and wiring and a weekend in the shop and you are in business to get accurate seating force measurements

Last edited:

The arbor press, both with K&M and 21st Century are really accurate. We tested both extensively. You need to go slow to read the guage. We tested both against each other and used a load cell to verify. They dont have the 50,000 pound or whatever compound leverage of a press. Mattyou would need to get a robotic right arm calibrated to be able to get a consistent steady pull on the lever every single time applying the same exact pressure at the exact same speed or the readings will vary no matter what press and pressure sensing setup you are using. The accuracy of any test can only be as accurate as the least accurate component of the test procedure, which in the case of an arbor press would the person pulling the handle which is why I have not ordered a hydro press long ago.

edit -

Arbor press of choice - $100

4 channel data logger - $200 https://www.onsetcomp.com/products/data-loggers/ux120-006m

AC gear motor with a reverse ??

Pulley, cable and wiring and a weekend in the shop and you are in business to get accurate seating force measurements

Last edited:

J F Johannes

AKA "RatRifle"

I'm not quite sure what all that means but I gotta have one.That's the new laser model no needle required " very cool

This exciting new technology divides the number of the unit by the factor !

Darrin

The arbor press, both with K&M and 21st Century are really accurate. We tested both extensively. You need to go slow to read the guage. We tested both against each other and used a load cell to verify. They dont have the 50,000 pound or whatever compound leverage of a press. Matt

your muscle memory may be very very good and you may have the ability to apply the same force on the pump or press lever consistently but I sure don't.

If force changes on one side of the equation the force will change proportionally on the other side whether the press transmits via gears or a hydraulics. That's high school physics. All manually operated presses do is transfer force from your body to the object seating the bullet. Whether the press is conventional linkage, Co-axial linkage, gear operated or if the force is transmitted hydraulically the presses only function is to transfer energy and multiply force. Just speaking for myself there is no way I could apply that force consistently enough to matter.

Now just to confuse everyone the, energy used to seat the same bullet in the same case each time would be exactly the same at the end of the day assuming all exterior factors affecting the resistance on the bullets movement are exactly the same. That is what we are trying to measure. To get meaningful measurements you need some way to make sure the energy applied is constant and then measure the amount of energy required or record peak force applied from a consistent and repeatable source of energy when seating. If force applied is inconsistent then there is no way to separate the force inconsistency from the friction inconsistency

edit - after some thought I believe most here could get fairly consistent on operation but when seeing a pressure spike there would be the question of whether I applied the force faster or slower than on the previous round. It would require some serious concentration but then so does firing that round properly. If a manufacturer came out with a electro mechanical version of the K&M hydro with a digital data recorder for $1000 I think they would sell quite a few to precision shooters. I would seriously consider putting one under my Christmas tree and my shooting is not nearly as precise as I would like

Last edited:

dcali

Bullet Maker

It's over three feet long, and would not fit.Where's the needle?

Darrin

I would think with the leverage in a Rockchucker press that it would be hard to get accurate measurements. I would even think the speed at which you pull the handle would change the pounds of force. You are talking alot of leverage. Much better getting a 21st Century or K&M arbor press with the guages. Matt

I think you can get a better feel with a arbor press for tighter or uneven seating force with or without a gage but the consistency of the force applied would still be uneven and therefore any reading would still be suspect.

I found some really inexpensive 1- 50 pound digital postal scales with high reading locks you could put under a Wilson seating die that would do the same thing as a gage for those who think they can provide a constant and repeatable pressure on the handle. Another thought on getting the force consistent would be to extend the operating lever and put a weight on the end of the lever and let the weight seat the bullet. That would give a consistent force for comparison. Spring loading the ram would be another simple alternative.

With the gauges, you need to go slow to read. When you go slow, the force required is about equal. If you never seated with an arbor press, you need to visit somebody who has and try it. Everybody i ever had seat a bullet with one, bought one. MattI think you can get a better feel with a arbor press for tighter or uneven seating force with or without a gage but the consistency of the force applied would still be uneven and therefore any reading would still be suspect.

I found some really inexpensive 1- 50 pound digital postal scales with high reading locks you could put under a Wilson seating die that would do the same thing as a gage for those who think they can provide a constant and repeatable pressure on the handle. Another thought on getting the force consistent would be to extend the operating lever and put a weight on the end of the lever and let the weight seat the bullet. That would give a consistent force for comparison. Spring loading the ram would be another simple alternative.

With the gauges, you need to go slow to read. When you go slow, the force required is about equal. If you never seated with an arbor press, you need to visit somebody who has and try it. Everybody i ever had seat a bullet with one, bought one. Matt

I really see no need to change anything in my reloading techniques at the moment. An arbor without a gage may be in my future but for now I doubt it would do anything for my shooting. Unless you have a way to apply consistent force at a consistent speed any readings on a gage are suspect at best because any deviation in the stroke will give a different reading.

My only complaint with my scores now has to do with shooting technique issues. Wind, mirage, and group centering are my score killers not the occasional flyer. A few bricks of quality .22LR down the barrel with windflags and the targets shot at 100 and 200 combined with a lot of .223 shot at 300 and 600 will do my scores more good than any new reloading gear.

Once my horizontal spreads are consistently equal to or smaller than my vertical spreads I will re examine my loading techniques and rifle. My loading technique has has hardly changed at all in the last 12 months but my scores improve with each new month because of practice not new bench toys or $5000 scopes. When they stop improving then I will look for something to get the momentum back but for the moment I feel as if my money is better spent on consumables and trigger time

My original idea of a hydraulic system or gear motor would probably be too costly and complicated to be cost effective but after mulling it over I think a spring operated system may be able to accomplish the same thing for less money. Someday I may buy a Grizzly or K & M arbor and see if I can modify it with a spring or a leveraged weight to apply force consistently then use a digital scale or load cell to get the readings

Dusty Stevens

Shiner

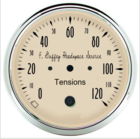

With the pressure gauge on the 21st and the correct technique when you start seating its high then it levels out until you bottom out. I can read the seating pressure just fine as can everybody else thats used one- no robotic arm needed. Dont dismiss a piece of equipment everybody thats ever had one says works when youve never pulled the handle on one. Theres a reason you never see any for sale used

I am ordering a Bald Eagle or K&M press and a Wilson micrometer seating die in .260 Rem today because I have been convinced me a arbor press will provide better "feel" when seating for a while now. I can feel some changes in pressure using a RC but a arbor would be more sensitive. Offtopic but I have been using a .308 Forster micrometer seating die on my .260's for over 7 years now and my runout has been consistently below .0015. I did not have a lot of extra cash for a micrometer die when I went to .260 and when the .308 worked I decided why bother. If it works don't mess with it and all that

back to the pressure gage. I am not trying to troll or be a butthead but physics is physics and the laws of hydraulics are the same in any application and they state that the pressure of a fluid is defined as the force acting per unit area within the fluid, change the force acting upon the fluid and you change the pressure. Change the pressure on one side of a hydraulic cylinder and piston assembly and you change the pressure on the other side proportionally. If you want to measure changes in force on one side of a hydraulic system consistent force will have to be applied to the other side of the cylinder. That's just the way the laws of physics work

Pascal's law, the Bernoulli equation and Newtons second law of motion all apply to basic hydraulic theory if you want to dig deeper.

In the meantime I am still looking for a inexpensive data logger and a strain gage capable of measuring in the 0 - 100 or 200 psi range. I am thinking a pneumatic cylinder or weight and pulley system might be the simplest and cheapest way to get a consistent force. I would think most of us already have a air compressor in the garage. A better way to measure seating pressure would make a good winter project but I need to do it for less than $500 total. If all else fails a cheap $20 scale with high reading lock would give max pressure but a data logger would be needed to measure breakaway force needed and change in the sliding friction. Ideally there should be a spike as the bullet starts to move and then the force should be a smooth slope until seating depth is reached if the force applied is constant from beginning to end.

Any press manufacturer or hobbyist with a home machine shop should be able to design and build one in a week or two, my feeling is they are not cost effective however. Off topic but my next house will have a Smithy set up in a corner of my shop for playing with projects like this

back to the pressure gage. I am not trying to troll or be a butthead but physics is physics and the laws of hydraulics are the same in any application and they state that the pressure of a fluid is defined as the force acting per unit area within the fluid, change the force acting upon the fluid and you change the pressure. Change the pressure on one side of a hydraulic cylinder and piston assembly and you change the pressure on the other side proportionally. If you want to measure changes in force on one side of a hydraulic system consistent force will have to be applied to the other side of the cylinder. That's just the way the laws of physics work

Pascal's law, the Bernoulli equation and Newtons second law of motion all apply to basic hydraulic theory if you want to dig deeper.

In the meantime I am still looking for a inexpensive data logger and a strain gage capable of measuring in the 0 - 100 or 200 psi range. I am thinking a pneumatic cylinder or weight and pulley system might be the simplest and cheapest way to get a consistent force. I would think most of us already have a air compressor in the garage. A better way to measure seating pressure would make a good winter project but I need to do it for less than $500 total. If all else fails a cheap $20 scale with high reading lock would give max pressure but a data logger would be needed to measure breakaway force needed and change in the sliding friction. Ideally there should be a spike as the bullet starts to move and then the force should be a smooth slope until seating depth is reached if the force applied is constant from beginning to end.

Any press manufacturer or hobbyist with a home machine shop should be able to design and build one in a week or two, my feeling is they are not cost effective however. Off topic but my next house will have a Smithy set up in a corner of my shop for playing with projects like this

Last edited:

Dusty Stevens

Shiner

I am ordering a Bald Eagle or K&M press and a Wilson micrometer seating die in .260 Rem today because I have been convinced me a arbor press will provide better "feel" when seating for a while now. I can feel some changes in pressure using a RC but a arbor would be more sensitive. Offtopic but I have been using a .308 Forster micrometer seating die on my .260's for over 7 years now and my runout has been consistently below .0015. I did not have a lot of extra cash for a micrometer die when I went to .260 and when the .308 worked I decided why bother. If it works don't mess with it and all that

back to the pressure gage. I am not trying to troll or be a butthead but physics is physics and the laws of hydraulics are the same in any application and they state that the pressure of a fluid is defined as the force acting per unit area within the fluid, change the force acting upon the fluid and you change the pressure. Change the pressure on one side of a hydraulic cylinder and piston assembly and you change the pressure on the other side proportionally. If you want to measure changes in force on one side of a hydraulic system consistent force will have to be applied to the other side of the cylinder. That's just the way the laws of physics work

Pascal's law, the Bernoulli equation and Newtons second law of motion all apply to basic hydraulic theory if you want to dig deeper.

In the meantime I am still looking for a inexpensive data logger and a strain gage capable of measuring in the 0 - 100 or 200 psi range. I am thinking a pneumatic cylinder or weight and pulley system might be the simplest and cheapest way to get a consistent force. I would think most of us already have a air compressor in the garage. A better way to measure seating pressure would make a good winter project but I need to do it for less than $500 total. If all else fails a cheap $20 scale with high reading lock would give max pressure but a data logger would be needed to measure breakaway force needed and change in the sliding friction. Ideally there should be a spike as the bullet starts to move and then the force should be a smooth slope until seating depth is reached if the force applied is constant from beginning to end.

Any press manufacturer or hobbyist with a home machine shop should be able to design and build one in a week or two, my feeling is they are not cost effective however. Off topic but my next house will have a Smithy set up in a corner of my shop for playing with projects like this

Youre right about the hydraulics, but with this press youll just have to see it in action. It matters how big your pressure ring is, case mouth chamfer, friction, seating depth etc. you cant use a max hold/recall just because of the way it works all together. And if you dont have the right stroke and know what to look for youll never catch the seating force we’re looking for. Once you get it youll see. None of the electronic projects youre thinking about will help with this. I like the hydraulic arbor presses over the k&m belleville washer setup

Youre right about the hydraulics, but with this press youll just have to see it in action. It matters how big your pressure ring is, case mouth chamfer, friction, seating depth etc. you cant use a max hold/recall just because of the way it works all together. And if you dont have the right stroke and know what to look for youll never catch the seating force we’re looking for. Once you get it youll see. None of the electronic projects youre thinking about will help with this. I like the hydraulic arbor presses over the k&m belleville washer setup

I am sure that with practice you could spot anomalies in the pressure with the hydro unit with practice. I would imagine the gage would be fairly snsitive. Without a gage I can sense a difference between a case neck lubed with Imperial dry and one that is not using a Rockchucker. I expect the arbor will give me even better tactile feedback. At least that is what I am telling myself as a incentive to buy one. Common sense tells me my ammo is more already more accurate than I am capable of shooting it so I should catch up to it before making changes.

edit - darn you guys - now I am second guessing myself and seriously considering a hydro unit. I think I will sleep on this another day or two. Question - can you seat a .264 VLD style bullet with a single ram stroke if the ram is pre positioned on the die.

and apologies to the OP for derailing this thread. I should have started a separate one

Last edited:

Even without a gauge, when using the inline dies on an arbor press I can feel anomalous 'seaters' that are seating way soft or way hard and can cull them for use as foulers or first sighters. With a gauge I can sort them in perhaps two different groups for separating them into different strings of fire. However, with very stringent and consistent case prep I find less segregation needed.

Ccrider

Gold $$ Contributor

Even without a gauge, when using the inline dies on an arbor press I can feel anomalous 'seaters' that are seating way soft or way hard and can cull them for use as foulers or first sighters. With a gauge I can sort them in perhaps two different groups for separating them into different strings of fire. However, with very stringent and consistent case prep I find less segregation needed.

You can feel someb of these differences with s Coax too. Just not as sensitive as the arbor press. I am more interested in trying to figure out the cause. I am pretty sure it’s poor case prep on my part.

Still, the differences in seating pressure do not consistently show on the target.

There is no direct correlation between seating force and neck tension(what actually matters) until FRICTION is normalized.Still, the differences in seating pressure do not consistently show on the target.

Similar threads

- Replies

- 2

- Views

- 489

- Replies

- 19

- Views

- 5,050

- Replies

- 9

- Views

- 1,548

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.