You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cloudrepair

Silver $$ Contributor

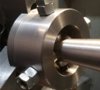

A couple ideas for using the spiders I sent you that will prevent barrel flex.

You could also duplicate the radius on the set screws I sent grinding some hss to match.

This is a very stable setup that can eliminate barrel flex.

Instead of the four jaw

You could also duplicate the radius on the set screws I sent grinding some hss to match.

This is a very stable setup that can eliminate barrel flex.

Instead of the four jaw

Attachments

I just went thru that on my lathe last week. Threads started looking a little rough until I adjust the crossslide and compound Gibs, that made all the difference in the world.

Being a new lathe and your using threading inserts it looks like the gibs may need to be tightened up on the compound and cross slide

View attachment 1031362

View attachment 1031362

The lathe is for chambering only it is a UCIMU made in ItalyView attachment 1031362this other lathe I do extractor cuts on.What model lathe you running there Stan ?

Last edited:

Someoldguy

I won’t have my go gauge for a week and want to practice more.

Would that be the same gauge you've posted a 'want to buy' ad for in the forum Marketplace'?

Well they seem to shoot pretty good it is hard to teach a old dog new tricks you know.lolACK!!!! A turret lathe!! With a steady rest no less!!Blasphemy.

I bet none of those barrels ever shot any good either, right?

mram10

Lots to reply to. Looked at the threader insert and it was actually a turning tool. 60deg, but nose was flat. I just grabbed some steel to mount the lathe to and give it a once over making sure all is level and true. Was going to order a go gauge, but found a member selling one, so that helped.

Going to stick to using a relief cut. There are .050 of threads under the recoil lug in case I need to set it back a little. Also, got my threading inserts today! Should fix any issues I’m having with wrong depth, angle, size, shape, etc.

Going to stick to using a relief cut. There are .050 of threads under the recoil lug in case I need to set it back a little. Also, got my threading inserts today! Should fix any issues I’m having with wrong depth, angle, size, shape, etc.

mram10

The barrel was a cm stock rem barrel. Sorry it took so long. Did another practice, won’t post pics, but it worked out much much better. Tried out my new carbide threading inserts and they made a world of difference. I like hss when it is shaped right, but I like that the inserts require no work.

These new carbide inserts what speed are you threading at .The barrel was a cm stock rem barrel. Sorry it took so long. Did another practice, won’t post pics, but it worked out much much better. Tried out my new carbide threading inserts and they made a world of difference. I like hss when it is shaped right, but I like that the inserts require no work.

mram10

Stan, 1100 rpm.

paperpuncher

Gold $$ Contributor

Your'e threading at 1100 RPM?Stan, 1100 rpm.

hogpatrol

Gold $$ Contributor

I like Tubecain's work but but cutting steel threads that technique unloads the carriage when making serious cuts.

Just curious and for the sake of discussion, what would be the size of a serious cut? For gunsmith thread cutting, most of it's light or ultralight cutting. For me, cutting 8 or fewer threads per inch on large diameters might be considered serious thread chasing.

WHAT ?Stan, 1100 rpm.

mram10

I thread at 180 and cut the shank at 1100

Just curious and for the sake of discussion, what would be the size of a serious cut? For gunsmith thread cutting, most of it's light or ultralight cutting. For me, cutting 8 or fewer threads per inch on large diameters might be considered serious thread chasing.

More of a generalisation. The technique on a light lathe may be problematic but if very light cuts are taken it may be fine. I can see merits in the technique but not in every situation.

It may be better to have insert and tool upside down cutting on the back side and run the leadscrew in reverse but chuck in normal rotation relative to cutting a rh thread. More than one way to skin the cat.

Last edited:

hogpatrol

Gold $$ Contributor

More of a generalisation. The technique on a light lathe may be problematic but if very light cuts are taken it may be fine. I can see merits in the technique but not in every situation.

I may be better to have insert and tool upside down cutting on the back side and run the leadscrew in reverse but chuck in normal rotation. More than one way to skin the cat.

I don't cut threads that way. I prefer to see what I'm doing.

This seems to be the common theme, when it comes to tooling, in most of these threads,,,,,I like hss when it is shaped right, but I like that the inserts require no work.

"I want, but I don't want to work for it"

The quest for knowledge and "know-how" should be never ending, not even for the hobby guys. You probably won't discover anything new because this 'industrial revolution' has been underway since the late 1700s, and there have been some pretty sharp characters solving problems and situations full time, around the clock since then. You will have learned something, if you learn to hand grind turning and threading tools for your use on your lathe. Something that just might apply to another problem or situation you'll encounter later on. The lessons I have learned by 'doing' over the passed 40+ years of machining are the lessons I won't soon forget. Even the "old guys" still pick-up on the subtleties they encounter cutting steel everyday if they keep their eyes open and don't just run on "auto pilot". Many things learned in one sector of the industrial arts can apply to some other task you might undertake. By not learning to hand grind those turning and threading tool from a high speed blank an opportunity has been lost. By picking that insert out of that little box and fastening it to its tool holder, someone else has "done it for you" in your haste to 'chamber your own barrels'. You have 'robbed' yourself of a learning opportunity that might help you with a problem later on in your barrel chambering.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.