I guess I was bored today and I'm sure this has been discussed before at some point but I'll let you know what I found anyway.

Let me start by saying I weighed 10 random pieces in every sample.

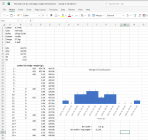

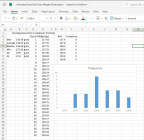

I started by weighing same yr LC 223 brass and found about a max spread of 1.2gr in LC 10 and 1.1gr in some LC 14. I then weighed some once fired 22-250 brass that was cleaned but not processed and it had a max weight difference of 1.4 gr. and then I weighed some once fired but processed Prime 6.5 CM brass and found about the same weight difference.

So I then decided to start weighing my reloads vs factory loads and taking into account the 1.0-1.5gr difference in just the brass I wanted to see how factory ammo compared to my own loads. I won't get into specifics, but I weighed 2 different batches of my 223 loads, 2 batches of my 22-250 loads, and a batch of my 6.5 Creedmoor loads and found a MAX spread of between 1.2gr to 1.7gr of my own loaded ammo so I assume most of that weight difference is strictly in the brass weight differences.

I then weighed 3 different 223 factory loads, one 204 Ruger factory load, and 3 different 22-250 factory loads.

I was finding anywhere from 1.4gr to 3.9gr differences in factory ammo. The Frontier 223 55gr HP Match had the lowest spread, but everything else had double or more the difference in weights. There was a 3.9gr difference in some 204 Ruger factory ammo which surprised me to see that much of a difference in a smaller case like that. 2 of the 3 different 22-250 factory loads I weighed were within about 2.5 -2.7gr, but one was almost 3.5gr. and I suppose that's why that last factory load was the least accurate out of my 22-250 and the other two were about the same and pretty decent for accuracy.

At any rate, I just found this interesting today and thought maybe some of you would too. If nothing else it affirms why I reload and the #1 reason is to get much more consistent ammo than factory ammo can give me plus the cost difference is definitely a benefit as well.

Have a good weekend and I'm looking forward to Super Bowl 1/2 time commercials tomorrow, the game itself doesn't mean much to me since my team didn't make it. GO NINERS!

GO NINERS!

Let me start by saying I weighed 10 random pieces in every sample.

I started by weighing same yr LC 223 brass and found about a max spread of 1.2gr in LC 10 and 1.1gr in some LC 14. I then weighed some once fired 22-250 brass that was cleaned but not processed and it had a max weight difference of 1.4 gr. and then I weighed some once fired but processed Prime 6.5 CM brass and found about the same weight difference.

So I then decided to start weighing my reloads vs factory loads and taking into account the 1.0-1.5gr difference in just the brass I wanted to see how factory ammo compared to my own loads. I won't get into specifics, but I weighed 2 different batches of my 223 loads, 2 batches of my 22-250 loads, and a batch of my 6.5 Creedmoor loads and found a MAX spread of between 1.2gr to 1.7gr of my own loaded ammo so I assume most of that weight difference is strictly in the brass weight differences.

I then weighed 3 different 223 factory loads, one 204 Ruger factory load, and 3 different 22-250 factory loads.

I was finding anywhere from 1.4gr to 3.9gr differences in factory ammo. The Frontier 223 55gr HP Match had the lowest spread, but everything else had double or more the difference in weights. There was a 3.9gr difference in some 204 Ruger factory ammo which surprised me to see that much of a difference in a smaller case like that. 2 of the 3 different 22-250 factory loads I weighed were within about 2.5 -2.7gr, but one was almost 3.5gr. and I suppose that's why that last factory load was the least accurate out of my 22-250 and the other two were about the same and pretty decent for accuracy.

At any rate, I just found this interesting today and thought maybe some of you would too. If nothing else it affirms why I reload and the #1 reason is to get much more consistent ammo than factory ammo can give me plus the cost difference is definitely a benefit as well.

Have a good weekend and I'm looking forward to Super Bowl 1/2 time commercials tomorrow, the game itself doesn't mean much to me since my team didn't make it.