Sounds like a job for a quantum computer. We may never know.

Let me expand a little bit more on my theory of neck tension and brass

let us first say

We take a piece of brass flat bar and bend it at 45 degrees

Then we straighten it back out flat

Then anneal it

-----------------------------------------

I believe many people are under the impression of we give it a little extra back bend this will build in more memory tension

So now we bend it at -10 degrees and bend it back out to 45 degrees

-----------------------------------------

Bending it at -10 degrees first before then bending it to 45 degrees does not make the brass spring back to 35 degrees

It stays at whatever angle we bend it to

both pieces may have 2-3 degrees spring back after bending to 45.... sure.

But putting any back bend does not make it spring back more

-----------------------------------------

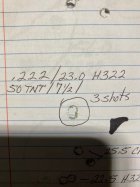

So I ran an experiment last night to try and proof my theory with some 22 BR brass

I neck sized 2 pieces of annealed brass, both with same neck thickness of .009"

1. was sized down to internal ID of .218"

2. was sized down to .221" ID

I then inserted a bullet into each one

-----------------------------------------

NOW - if peoples thoery is correct, the one that was sized down further should have some more built in spring back right? Or = More neck tension.

IF it is true that sizing the case down more builds in more neck tension, then when I pull the bullets out the one sized down to .218" should spring back further to less of an ID.

---more than the brass that was sized down to .221"

------------------------------------------

When I pulled each bullet and measured the ID of each case

They were both exactly the same .224

The case that was sized down smaller did not spring back further

------------------------------------------

Yes it may take more seating pressure to seat a bullet into the .218 neck sized case

because you are stretching the brass more

But once it is stretched, they are both stretched the same amount

------------------------------------------

I will however admit that if we do not anneal, sizing down more will work harden the brass enough to allow MORE spring back if sized down further and possibly apply more neck tension

Yet if we are annealing our brass so all cases are just as soft and stretchable

Once stretched....it does not matter if I sized the neck down to .100, then seat a bullet.

-----------------------------------------

This is with MY brass at MY neck thickness

Other brass with thicker necks may act differently

which is why I say,

"Tuning your neck tension is done with neck thickness, more so than the dia. it is sized down to."

Hope this makes sense