I had a customer recently tell me that he was aware of GM barrels but was concerned of the quality because the price was so much lower than other barrels. Not the first time I’ve heard this. Don’t get me wrong, I use any and all barrel manufacturers that are requested from the customer and honestly don’t think there is a bad barrel blank on the market today, unless one slips past the goalie, but due to increased machine standards that take out a lot of human error and guess work. It’s purely a simple matter of manufacturing economics. Let me explain…

I will use Green Mountain for this example, which is a button barrel, because I use a ton of them, have a long working relationship with GM, (in addition to Krieger, Bartlein, Brux, ect.) and the rifled hole in the middle of the blank is done very well each time. I also know (haven’t confirmed lately) that they the largest privately held barrel manufacturer in the US and supply a great deal of OEM barrels to firearms manufacturers in the US and internationally. They don’t advertise to the end user for the same reason BASF doesn’t, although BASF has a hand in almost anything manufactured today. They didn’t get to this point over the decades by producing crap.

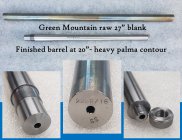

They start by using steel bar stock that is produced to their spec, deep hole drill / ream that stock to size, and force a carbide button just like any button barrel manufacturer has done for the last 70 years. The barrel stock can now be called a rifled barrel blank. That blank is then stress relieved in a nitrogen oven, turned between centers so that the hole goes down the middle of the blank diameter, then stress relieved again. The barrel blank then goes through inspection before it makes it to the shipping dept. This process is performed thousands of times a month which brings the individual piece price down dramatically compared to a manufacturer a fraction of their size. I don’t know exactly how long one piece takes to produce due to batch processing, but I know when producing in such large lot sizes, it ain’t long. Obviously, there’s a great deal more here to be articulated, but there it is in a nutshell. They employ a significant number of American workers to produce this product, turn a good profit at their spot price, and have an unbelievable backlog.

End user pricing is based on cost to produce. We already discussed the origin of the product, now let’s move to the finish machine process that consists of many reputable small companies like mine and others across the country that service the industry. Speaking for myself and using a RimX pre-fit barrel for illustration purposes, we continue. Once the barrel blanks are in stock, they are loaded into a CNC lathe for contour and action thread spec. They are cut to desired length and again loaded into the CNC for muzzle threads if needed. All diameters are checked and threaded tenons are checked with a ring gage for a 3B fitment. At this point the barrel is visually taking shape. The barrel is then loaded into a manual tool room lathe for specific chambering, unless a large quantity is ordered of the same exact piece. The chamber is then polished and moved to another lathe for crowning. Once the barrel is more or less complete, it’s polished, marked, and packaged for shipment. The entire finish process from the time the barrel blank arrives takes about a half hour to complete barring any hicups along the way. Just for reference, this process took Remington about a minute and a half to completely produce a center fire barrel.

To sum things up, time is money. The only way to take less time is to streamline using automated tooling and evolved processes in order to produce without sacrificing quality. When I first started, this process took all morning for one piece. Things change, processes change, people learn from mistakes, ect, ect… All of this time cost is considered to offer pricing that will deliver a great product as well as turn an acceptable profit. No one works for free, nor should they ever be expected to. This is capitalism at it’s finest. I hope it stays around a little while longer.

Now, for an insider’s scoop….some in this industry happen to use Green Mountain barrels and call them by their own made up name or say “this is proprietary info”, never the less, it’s a good product and mainly comes down to the finisher. Other finishers must include multiple layers of profit in order to pay both the guy you are buying the barrel from as well as the guy who is actually doing the work in addition to anyone else in the chain of sale and distribution.

Hope this sheds some light on the subject…

JS

I will use Green Mountain for this example, which is a button barrel, because I use a ton of them, have a long working relationship with GM, (in addition to Krieger, Bartlein, Brux, ect.) and the rifled hole in the middle of the blank is done very well each time. I also know (haven’t confirmed lately) that they the largest privately held barrel manufacturer in the US and supply a great deal of OEM barrels to firearms manufacturers in the US and internationally. They don’t advertise to the end user for the same reason BASF doesn’t, although BASF has a hand in almost anything manufactured today. They didn’t get to this point over the decades by producing crap.

They start by using steel bar stock that is produced to their spec, deep hole drill / ream that stock to size, and force a carbide button just like any button barrel manufacturer has done for the last 70 years. The barrel stock can now be called a rifled barrel blank. That blank is then stress relieved in a nitrogen oven, turned between centers so that the hole goes down the middle of the blank diameter, then stress relieved again. The barrel blank then goes through inspection before it makes it to the shipping dept. This process is performed thousands of times a month which brings the individual piece price down dramatically compared to a manufacturer a fraction of their size. I don’t know exactly how long one piece takes to produce due to batch processing, but I know when producing in such large lot sizes, it ain’t long. Obviously, there’s a great deal more here to be articulated, but there it is in a nutshell. They employ a significant number of American workers to produce this product, turn a good profit at their spot price, and have an unbelievable backlog.

End user pricing is based on cost to produce. We already discussed the origin of the product, now let’s move to the finish machine process that consists of many reputable small companies like mine and others across the country that service the industry. Speaking for myself and using a RimX pre-fit barrel for illustration purposes, we continue. Once the barrel blanks are in stock, they are loaded into a CNC lathe for contour and action thread spec. They are cut to desired length and again loaded into the CNC for muzzle threads if needed. All diameters are checked and threaded tenons are checked with a ring gage for a 3B fitment. At this point the barrel is visually taking shape. The barrel is then loaded into a manual tool room lathe for specific chambering, unless a large quantity is ordered of the same exact piece. The chamber is then polished and moved to another lathe for crowning. Once the barrel is more or less complete, it’s polished, marked, and packaged for shipment. The entire finish process from the time the barrel blank arrives takes about a half hour to complete barring any hicups along the way. Just for reference, this process took Remington about a minute and a half to completely produce a center fire barrel.

To sum things up, time is money. The only way to take less time is to streamline using automated tooling and evolved processes in order to produce without sacrificing quality. When I first started, this process took all morning for one piece. Things change, processes change, people learn from mistakes, ect, ect… All of this time cost is considered to offer pricing that will deliver a great product as well as turn an acceptable profit. No one works for free, nor should they ever be expected to. This is capitalism at it’s finest. I hope it stays around a little while longer.

Now, for an insider’s scoop….some in this industry happen to use Green Mountain barrels and call them by their own made up name or say “this is proprietary info”, never the less, it’s a good product and mainly comes down to the finisher. Other finishers must include multiple layers of profit in order to pay both the guy you are buying the barrel from as well as the guy who is actually doing the work in addition to anyone else in the chain of sale and distribution.

Hope this sheds some light on the subject…

JS

Attachments

Last edited: