You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Attention all hoarders......

- Thread starter bobm

- Start date

I had cans from my father that had 79 cents on them, I had 57 cans late 50’s 60’s 70’s 57 of them some never opened some open, a guy gave me 1500 for all of themSome of my oldest cans.....when's the last time you paid $3.49 for a pound of powder?

View attachment 1416501

no so. the powder and the can/rust are not one product like soup mixed with can would be.Ok so based on what I've seen and read in this thread a combination of metal cans and storage in environments with little or no temperature and humidity controls are probably what causes problems.

A can of soup from the 80s wouldn't be fit to eat. Makes sense powder would be questionable at best.

i have proven and tested that in cases where RUST is the only issue, it can be removed, the powder can be tested and shot. yes it takes time, but some of us with out stacks of money have time to invest in our sport.

END OF REPLIES

DShortt

Gold $$ Contributor

I never said nor implied it was a money issue. It's a safety issue. If you're convinced that's a bet worth making obviously it's your decision.no so. the powder and the can/rust are not one product like soup mixed with can would be.

i have proven and tested that in cases where RUST is the only issue, it can be removed, the powder can be tested and shot. yes it takes time, but some of us with out stacks of money have time to invest in our sport.

END OF REPLIES

However your theory about a lack of a chemical/environmental reaction is incorrect.

Sorry if the reality upsets you. Wasn't my intention. It's simply fact.

I've spent a little time researching deterrents and how they are applied. It appears liquid coating is the method, but how. Probably batch submersed then dried? Multiple times dipped or in different batch concentrations? Adherence integrity? Is deterrent coating what gives the powder that glossy appearanceIf I remember correctly, extruded powder is surface coated with burn deterrents in order the regulate its burn rates.

Rust, rubbing perhaps other things have removed this coating. It's obviously contaminated.

EDIT......found it....

US3637444A - Process of making deterrent-coated and graphite-glazed smokeless powder - Google Patents

Text from an internet article:

Smokeless powder consists of nitrocellulose (single-base powders), frequently combined with up to 50 percent nitroglycerin (double-base powders), and sometimes nitroglycerin and nitroguanidine (triple-base), corned into small spherical balls or extruded into cylinders or flakes using solvents such as ether. Other minor ingredients, such as stabilizers and ballistic modifiers, are also added. Double-base propellants are common in handgun and rifle ammunition. Triple-base propellants are more common in artillery guns.

The reason that they are smokeless is that the combustion products are mainly gaseous, compared to around 55% solid products for black powder (potassium carbonate, potassium sulfate etc).

Smokeless powder burns only on the surfaces of the granules, flakes or cylinders - described as granules for short. Larger granules burn more slowly, and the burn rate is further controlled by flame-deterrent coatings which retard burning slightly. The intent is to regulate the burn rate so that a more or less constant pressure is exerted on the propelled projectile as long as it is in the barrel so as to obtain the highest velocity.

Cannon powder has the largest granules, up to thumb-sized cylinders with seven perforations (one central and the other six in a circle halfway to the outside of the cylinder's end faces). The perforations stabilize the burn rate because as the outside burns inward (thus shrinking the burning surface area) the inside is burning outward (thus increasing the burning surface area, but faster, so as to fill up the increasing volume of barrel presented by the departing projectile).

Fast-burning pistol powders are made by extruding shapes with more area such as flakes or by flattening the spherical granules. Drying is usually performed under a vacuum. The solvents are condensed and recycled. The granules are also coated with graphite to prevent static electricity sparks from causing undesired ignitions.

Last edited:

Skedaddle Shooter

Gold $$ Contributor

Your going to need a big magnetDo you think this is ok to use? Picked up the can and my fingers went right through it. Wouldn’t burn at all.

DShortt

Gold $$ Contributor

Very soon there will be another thread about how detrimental to barrel life shooting powder with iron oxide in it is. Lol

I hope this doesn’t start an “iron ring” next to or on top of any “carbon ring”

Attachments

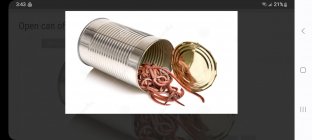

For those that have not yet checked the condition of your powder stored in steel cans. This photo is for you, the beginning stages of the photo shown in post #24.

Note the zone of little rust above where propellant had no contact with the can.

Additional photo under different lighting.

Note the zone of little rust above where propellant had no contact with the can.

Additional photo under different lighting.

Attachments

Last edited:

rjtfroggy

Gold $$ Contributor

I found a can of Dupont IMR 4320 on the shelf yesterday, bought in the early 70's, no signs of rust looks almost new. I removed the cap and no foul odor but sure enough "red dust" coating the powder.

It was probably less than $5 and if I haven't used it in over 50 years, I guess I won't miss it after I dump it out.

It was probably less than $5 and if I haven't used it in over 50 years, I guess I won't miss it after I dump it out.

Great lawn fertilizer.I found a can of Dupont IMR 4320 on the shelf yesterday, bought in the early 70's, no signs of rust looks almost new. I removed the cap and no foul odor but sure enough "red dust" coating the powder.

It was probably less than $5 and if I haven't used it in over 50 years, I guess I won't miss it after I dump it out.

The can of worms has been opened.What do you think about the red iron oxide potentially ruining the barrel like an abrasive? Any thoughts that way?

This from google search:

Is iron oxide abrasive?

Although not a major use, red iron oxide finds use as a mild abrasive, used especially for high-value cleaning and finishing applications, such as: Powder – usually mixed with an emollient and used for polishing fine silver.

What is red rouge polishing compound made of?

Jeweler's rouge is a jewelry polishing compound, used especially for achieving a high shine with precious metals such as silver and gold. Made from finely ground iron oxide, or more commonly known as “rust”, jeweler's rouge comes in a dark red color, following its namesake rouge.

------------------------------------------------------------------------------------------------------------------------

I would rather not have any iron oxide in quantity pushed through my barrels under high pressure.

Last edited:

No, it is crappy lawn fertilizer. Hodgdon told me to dispose of the recalled powder properly. What would that be? Burn it.Great lawn fertilizer.

Both you and I have old cans that appear in good exterior condition, but the contents have compromised the interiors. Mine discovered at 30 years, yours at 50. What conditions led to the complete transformation and destruction of the can in post #24?I found a can of Dupont IMR 4320 on the shelf yesterday, bought in the early 70's, no signs of rust looks almost new. I removed the cap and no foul odor but sure enough "red dust" coating the powder.

It was probably less than $5 and if I haven't used it in over 50 years, I guess I won't miss it after I dump it out.

Last edited:

Well that’s not terrible. Couldn’t be any worse than Flitz or IOSSO could it?The can of worms has been opened.

This from google search:

Is iron oxide abrasive?

Although not a major use, red iron oxide finds use as a mild abrasive, used especially for high-value cleaning and finishing applications, such as: Powder – usually mixed with an emollient and used for polishing fine silver.

What is red rouge polishing compound made of?

Jeweler's rouge is a jewelry polishing compound, used especially for achieving a high shine with precious metals such as silver and gold. Made from finely ground iron oxide, or more commonly known as “rust”, jeweler's rouge comes in a dark red color, following its namesake rouge.

------------------------------------------------------------------------------------------------------------------------

I would rather not have any iron oxide in quantity pushed through my barrels under high pressure.

Jguseil

Gold $$ Contributor

I can’t figure it out. I got that can and others when my father passed away in 1998. Some had been opened and some were still sealed. All of the cans were in great shape. This is the only can that deteriorated. I checked all of the opened cans and the powder in those looks and smells fine. I’m going to extra cautious if I ever get around to using it.No, it is crappy lawn fertilizer. Hodgdon told me to dispose of the recalled powder properly. What would that be? Burn it.

Both you and I have old cans that appear in good exterior condition, but the contents have compromised the interiors. Mine discovered at 30 years, yours at 50. What conditions led to the complete transformation and destruction of the can in post #24?

There you have it; rusty powder will iron out a rough throat.

Perhaps the next Hodgdon powder along the lines of CFE product line- IDTR Iron Dust Throat Rejuvinator. Hey- it doesn't sound any cornier than copper fouling ERASER.There you have it; rusty powder will iron out a rough throat.

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.