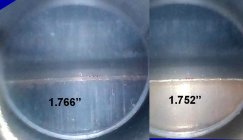

I think I have figured it out. It was a series of mistakes I will never make again. I built two AR's for a close friend, one of them being a .223. Well, he went out and bought 1000 rounds of once fired military brass. First problem, the cases are slightly less in volume, so produce more pressure. Then even though he was an experienced reloader, he had no case guage for .223 and did not measure his cases. These were the first two AR's he owned. He was getting on in years and passed four weeks or so ago. That's when I bought a lot of 1000 primed .223 cases from his estate, and promptly loaded them. I DID NOT CHECK CASE LENGTH. Second mistake. Some were nearly 1.780. This is why I was puzzled when I found cartridges overlength in my stuff, when I always measure. But I incorrectly assumed that he had measured them, because he had fifty years of reloading experience. I figured incorrectly that they had been measured, since I always measure and trim before I prime. My bad. Maybe he bought them pre-primed, I don't know, I never will. I should have measured them. That whole bad bag was all stuff from his estate. The combination of military brass and overlength I believe is what did it. The cases crimped when fired causing what was a mimic of a squibb in the chamber, blowing out the back of the brass and destroying the rifles. Had I trimmed the cases, given the loads even with the variances, they would have been fine. Never, ever, trust reloading from anyone else, period. That was the lesson. I got it. They were all either 25 grains of H335 or under, and my AR manual specifically lists 26 grains as max. for an AR. I am going back through all 1000 rounds and measuring each one with my Wilson Case guage, and pulling any one of them 1760 over. The powder wasn't the problem so I'm saving it and using it to reload all the correct length cases now. What a huge job. But I like my face. Thanks for all the replies.