BuffaloBill

Silver $$ Contributor

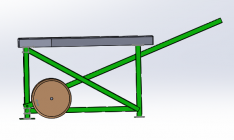

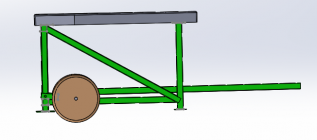

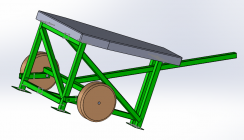

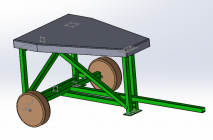

I have a farm to use as a gun range, but a permanent bench would in the way of farming activities. So I’m thinking about making one as shown below. The top would be concrete and shaped/dimensioned similar to those I read people liked at the St. Louis range (if I found the right discussion threads).

I believe the tongue weight would be about 90lbs with a total weight of about 550lbs. As drawn the tubing is 2” square. I liked the use of diagonals for rigidity and smaller tubing, as opposed to larger tubing w/o diagonals. I’m thinking 11ga wall thickness for the axle/tongue ass’y and 14ga for the rest of the tubing.

Do you think the axle ass’y is taking up too much foot room?

I believe the tongue weight would be about 90lbs with a total weight of about 550lbs. As drawn the tubing is 2” square. I liked the use of diagonals for rigidity and smaller tubing, as opposed to larger tubing w/o diagonals. I’m thinking 11ga wall thickness for the axle/tongue ass’y and 14ga for the rest of the tubing.

Do you think the axle ass’y is taking up too much foot room?