I was wondering what others are seeing for anneal times for the Annie? I have only done about 50 cases so far and was wondering what settings others are using for various cases. I have annealed thousands of cases with a benchsource but the results are a little different with the annie since there is no flame leaving much if any coloration.

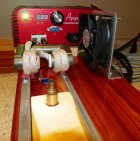

The picture is of some cull blue box 6br brass from various stages of forming dasher cases and annealed with the annie and 650 tempilac. necks are not turned. In a completely dark room I see the necks just start to glow about 3.2 seconds. anything less than 2.0 and I don't see the tempilac consistantly turn color on all of the neck.

I did some 260 lapua at 2.3 seconds and the neck tension was cut from about 50-60 lb to 18-24 seating force on my hydro seater and seated very nice.

-

101_0222xx.jpg

127.9 KB

· Views: 149

I determine annealing time on my BenchSource using the neck glow method i.e. if the setting gives a slight red glow, I dial down ¼ of a second so that there is no glow and that is the right time. Should not be any different with the Annie?

What Tempilac are you using and are you using the neck glow method with the Benchsource and if so how does that affect neck tension? i.e. are they the same or different than with the Annie?

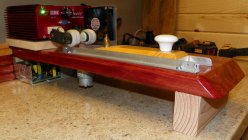

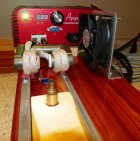

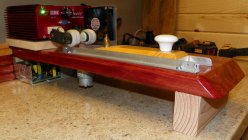

Here are a few pictures of my setup for the annie. I can add various spacers under the annie to raise it up for taller cases. I also installed a small 12v motor that spins the cases while being annealed. The shuttle has a stop at the front that stops it in the exact same spot on top of the spinner so that the cases are always in the same position while being annealed. When I pull it all the way back the case drops through the hole into a cake pan and then I slide it forward a 1/2 inch and place a new case in and start over.

The 12v fan I have moves a fair amount of air and may be slowing my anneal times down compared to others.

-

101_0223x.jpg

160.9 KB

· Views: 218

-

101_0226x.jpg

115.2 KB

· Views: 220

-

101_0228x.jpg

126.4 KB

· Views: 189

jlow, most of my anneal times with the benchsource were around 3-4 seconds. One of the reasons I am asking about times is that the annie manual says most cases anneal in under 2 seconds but i don't think that's really enough from what i am seeing. The actual neck is annealed at 2.0 but I'm not really sure if it's migrating enough into the shoulder. The brand is Tempil. I haven't done enough to compare seating results yet.

Dakota_Mike – that is a sweet setup! Very nicely done indeed. Some good ideas there!

My experience with the BenchSouce is that the annealing time can and do vary even with the same case and torches since the aim, flame strength, and distance to the case neck/shoulder can very with each setup but my time is around 3-5 seconds.

I personally find it hard to see how the company that makes the Annie can know the exact correct time since even though they can control the distance and strength of the annealing because the size, thickness of the neck can affect it, plus as you say air movement. So my guess is that that is just a very generalized statement not to be taken too literally.

One of the potential difference between the torch-base vs. the induction-based annealer is it seems like the induction-based annealer is a slight bit more focus in terms of the area of the neck that it anneals and this of course can affect how far up or down the neck/shoulder the anneal affects. The flame-based especially the two torch approach can in fact be more diffuse especially if you aim one at the neck and one lower down to the shoulders which is what I do since I want to anneal both areas.

In general and just speaking off the top of my head, It would seem that one would not want the anneal area to spread because that would imply that the center area would in fact get hotter than the desired temperature. I think what we are looking for is a relatively even anneal?

Still, without testing, it would be hard to see if the two are equivalent? Some seating force measurement would help you figure out the necks but I am not sure how one would test the shoulder and the area between it and the neck?

I've only had my Annie for a week and have used it twice so I'm not exactly sure that I'm doing it correctly but am seeing very similar results as you. I've only done Lapua .260 cases and found that 2.1 seconds had the case mouth just starting to glow. I'm only getting the color change down to just above the neck/body junction and 750 Tempilaq confirms this. It seems that the process happens so fast that the temp doesn't travel as far down as it would using the torch method. It heats up so fast that I hold the brass in my bare hands without getting burned. I bumped shoulders on this brass after annealing it and found the shoulder to base measurements to be very consistent, which is what I'm looking for, so I'm not concerned about the temp not getting high enough on the lower shoulder. I'm hoping for consistent neck tension which it sounds like you have achieved.

I'm using the jaws that are the closest together and pushing the brass in horizontally far enough to catch the shoulder and neck.

So far I'm am completely pleased with the unit. Works as advertised and very easy to set up. Garett promised me a foot pedal when I ordered it however forgot to send it but I'm sure he will after I email him.

You are not going to know whether you have done it right after 1or 2 uses, the reason being that your brass does not work harden that fast.

In terms of the jaws, it sounds like you have a choice i.e. some are closer together. My guess is the closer together one will anneal faster and that is why its done in 2.1 seconds. Faster is not always better as you have already said, the heat may not have time to travel. Do you have thicker jaws? That might help the shoulders.

jlow said:

You are not going to know whether you have done it right after 1or 2 uses, the reason being that your brass does not work harden that fast.

In terms of the jaws, it sounds like you have a choice i.e. some are closer together. My guess is the closer together one will anneal faster and that is why its done in 2.1 seconds. Faster is not always better as you have already said, the heat may not have time to travel. Do you have thicker jaws? That might help the shoulders.

Yeah I'm using the jaws that are recommended, if I understand their directions well, but that may be the thing to try. I may be misunderstanding the whole reason for annealing but my thought is that the neck is the important part that you're trying to condition back to normal. I was concerned about the shoulder however when I bump it I come up with the correct setback and they are consistent from case to case. I'd think that is what you would strive for. In the past when bumping shoulders after 4 or 5 firings I couldn't get consistent setbacks. I assume because the shoulder was springing back at a different amount. This was one of the reasons that I wanted to try annealing. I may have to try some of the different setups to see if I can slow the annealing time down to get the entire shoulder annealed.

Any thoughts on that from you veterans?

loneranger04 said:

jlow said:

You are not going to know whether you have done it right after 1or 2 uses, the reason being that your brass does not work harden that fast.

In terms of the jaws, it sounds like you have a choice i.e. some are closer together. My guess is the closer together one will anneal faster and that is why its done in 2.1 seconds. Faster is not always better as you have already said, the heat may not have time to travel. Do you have thicker jaws? That might help the shoulders.

Yeah I'm using the jaws that are recommended, if I understand their directions well, but that may be the thing to try. I may be misunderstanding the whole reason for annealing but my thought is that the neck is the important part that you're trying to condition back to normal. I was concerned about the shoulder however when I bump it I come up with the correct setback and they are consistent from case to case. I'd think that is what you would strive for. In the past when bumping shoulders after 4 or 5 firings I couldn't get consistent setbacks. I assume because the shoulder was springing back at a different amount. This was one of the reasons that I wanted to try annealing. I may have to try some of the different setups to see if I can slow the annealing time down to get the entire shoulder annealed.

Any thoughts on that from you veterans?

I anneal both the necks and shoulders. The neck for consistent neck tension, and the shoulders for consistent bump. Yes, after more firing, pretty sure the shoulder can work harden and that would cause inconsistent bump. I wonder if you can run the case through twice, once at the neck and one at the shoulder?

When I size and shoulder bump I leave the brass in the die for 10 sec.while I ready another piece of brass ( helps with spring back A LOT ). Then I remove it and put it in the comparitor die to make sure I am where I want to be. If not I put it back in the sizer and let it "cook" a bit longer then check again. Just a bit of something to chew on...... 8)

jlow said:

I anneal both the necks and shoulders. The neck for consistent neck tension, and the shoulders for consistent bump. Yes, after more firing, pretty sure the shoulder can work harden and that would cause inconsistent bump.

Same here (necks and shoulders) and the italics I added for the

very reason why I took up annealing cases back about ten years ago. Messing with two 6.5 Grendel match uppers back then & inconsistent shoulder bump was giving me fits. Side benefit back then was more consistent neck tension, now they're

both primary motivators.

This Annie thing sure is a neat gizmo but at this point my cash flow'll only support buying more propane for my torch....

Armored Transport said:

When I size and shoulder bump I leave the brass in the die for 10 sec.while I ready another piece of brass ( helps with spring back A LOT ).

That too but it sure extends a brass prep session when you're staring at a pile of 500+ cases....

I've found even a slight pause at the TDC point helps over wham-bam-style sizing operations.

Armored Transport said:

When I size and shoulder bump I leave the brass in the die for 10 sec.while I ready another piece of brass ( helps with spring back A LOT ). Then I remove it and put it in the comparitor die to make sure I am where I want to be. If not I put it back in the sizer and let it "cook" a bit longer then check again. Just a bit of something to chew on...... 8)

Your "trick" is well known. The only thing is it will only help slightly if your shoulders are work hardened and it will not help you if your shoulders have different degree of work hardening... The proper way to do this is to even things out by annealing. With that, you shoulders will effortlessly bump to the correct headspace every time.

Never did think of it as some sort of "trick". Just a little thing that has helped me.....Thought it might help you as well. Some day I hope to know so much as to not accept others "tricks".......

I did not use the word "trick" in a negative way in any sense. As I said, it does help but not in the case where there are different degrees of work hardening. That of course does not mean it would not help if you don't have an annealer and have brass with consistent degree of work hardening. I use "tricks" that people teach me all the time, sometimes they make all the difference.

I use my Annie for three cases, 6BRX, 284 WIN and 7X57.

I have experimented with both core spacings and various times while monitoring with 750 Tempilaq as well as brass glow with subdued lighting.

i found that while a bit slower, the wide spaced core seems to have a bigger flux concentration area so I get the tip all the way to a bit below the shoulder area pretty evenly heated. The 6BRX of course is only 1.8 sec or so, the 7X57 about 2.5 sec and the 284 Win about 2.8 sec.

The narrower core spacing makes for a tighter flux concentration with higher flux density so it heats faster, but it heats a smaller area.

I try to set the shoulder in the middle of the core. The neck will naturally heat up faster since there is less material.

I tried 2.2 sec on some dasher brass and it was a little too much. Neck tension was 10-14 where I normally seen 14-22 with the bench source.

Nice to see seating pressure differences from annealing. Great stuff. I like real numbers. It proves that annealing for a very short time at a low temperature does change the tension. If the shoulder is at 750F the neck has to be higher because it gets a faster heat transfer.

normmatzen said:

I use my Annie for three cases, 6BRX, 284 WIN and 7X57.

I have experimented with both core spacings and various times while monitoring with 750 Tempilaq as well as brass glow with subdued lighting.

i found that while a bit slower, the wide spaced core seems to have a bigger flux concentration area so I get the tip all the way to a bit below the shoulder area pretty evenly heated. The 6BRX of course is only 1.8 sec or so, the 7X57 about 2.5 sec and the 284 Win about 2.8 sec.

The narrower core spacing makes for a tighter flux concentration with higher flux density so it heats faster, but it heats a smaller area.

That is exactly what I was wondering about. The area of the induction field that affects the brass would be wider with the wider spaced core since the case is further away which will give you a more diffuse anneal. It would be slightly slower but that is of little consequence.

This thread is getting real informative. I have been waiting for this next batch of Annies for some weeks and I am really liking the sorting out of the unit that is going on here. Thank You... 8)....Keep it coming.......Rick