dellet

Gold $$ Contributor

As the title says, these are my first thoughts. Any one who has done any product testing, knows better than to believe any manufacturer that you haven’t previously developed a relationship with. or to get too hung up on yourself and your own way of thinking. Thinking this will never work, or be the best thing ever.

I have had serious doubts about the claims made for this bullet, and that a bullet more or less designed for a certain cartridge, 300 Blackout, took in to account the idiosyncrasies of that cartridge. I have raised these concerns in multiple threads, and have mostly been ignored.

Let’s make a few things clear. I never asked for free bullets, nor were any offered. My posts and questions to @HappyHellfire have been reasonably polite, but clearly contentious. I don’t expect any exchange in this thread to be much different. I can generally take what I give. Without running home to mother.

I am not a top notch or pro shooter by any stretch of the imagination, but the 300 BLK caught my attention and I think I understand the cartridge quite well. So when someone comes out with the magic bullet for that cartridge, I tune in. There are probably a couple people On this forum that will vouch for my knowledge, maybe a couple that will say I’m full of crap. That will sort itself out in the next few weeks testing this bullet takes. The longer it takes, the more promise the bullet has.

All that said as a disclaimer, let the rat killing begin.

Order places in the morning, tracking number before lunch, bullets in hand in a couple of business days. Pretty good service I’d say.

Opening the box and enclosed was some load data, drop chart and drag curve. This is where the problems begin. The drag curve plots the G7 norm, a non existent bullet and the Aerospike. This was discussed in one of the threads. It is basically a pointless comparison.

Then there is the load data. Min and Max. charge weights, but no loaded length. This will become critical later.

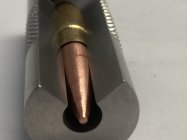

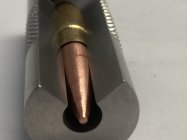

A Quick Look at the bullets raises some other concerns.

The parting on the base, leaves them any thing but concentric or repeatable. Maybe with the new tail design, the steering end is not important as I have been led to believe. If these were cast bullets, they would go back in the pot. Sorry for the dirty fingers.

Then there is tip of the nose. You can feel 2-3 transitions to the tip. Honestly not sure if the tip is centered.

First check is in a chamber gauge. Since the gauge also checks overall length, first thing I do is confirm it can be loaded to magazine length or longer. This bullet, in this chamber will touch the lands around 2.320”. Nice to know for a bolt action, and that loading to SAAMI max is safe.

But can it really be loaded to that length?

Take a look at where the boat tail begins and neck in the chamber ends. It’s easier to see here, but the bearing surface is so short and so far back, that the bullet is out of the case, before the ogive contacts the lands.m

So if you want a jam, and load from a magazine, it’s off the table. Not a deal killer, but…..

My brass is trimmed to 1.365”, .003” off max.this bullet will have minimum .060-.080” jump, before you seat the bullet in the neck depending on your trim length.

Easier to see with brass in the gauge.

The jump will already be .050”+, that will only grow as you begin to seat the bullet. I hope these bullets like a long jump, because it will be .200-.300”. It’s just not practical in a AR to only have .125” of bearing surface in the neck giving you only .175-200” jump.

Again this is first glance, a lot of what I’ve flagged here can be worked around. If you have the experience of a few different cartridges and thousands of rounds with different bullets under your belt. But at first glance this bullet will be frustrating for a lot of people to load and shoot. It may also be dangerous for a few novice loaders.

The first thing that needs to be included in the load data is a maximum COAl. Not to include that is asking for trouble.

Hopefully this weekend I can load some up, honestly I’m a bit worried about spin rate. I think it will quite possible that at a spin rate approaching 300,000 rpm’s, that nose may just be a problem. Maybe it will balance out the base. Who knows.

Anyone know if you can hold A bullet manufacturer responsible for a baffle strike?

Over time I’ll try and run this bullet in every twist from 5-10 and velocities from 900-2400 fps. Probably will have some interesting feed back.

I hope this helps some other folks that may be working with or considering this bullet.

All that will really matter is what the targets show, but initial load might take some time. I will load to the manufacturer tested velocity first, then develop my own loads.

I have had serious doubts about the claims made for this bullet, and that a bullet more or less designed for a certain cartridge, 300 Blackout, took in to account the idiosyncrasies of that cartridge. I have raised these concerns in multiple threads, and have mostly been ignored.

Let’s make a few things clear. I never asked for free bullets, nor were any offered. My posts and questions to @HappyHellfire have been reasonably polite, but clearly contentious. I don’t expect any exchange in this thread to be much different. I can generally take what I give. Without running home to mother.

I am not a top notch or pro shooter by any stretch of the imagination, but the 300 BLK caught my attention and I think I understand the cartridge quite well. So when someone comes out with the magic bullet for that cartridge, I tune in. There are probably a couple people On this forum that will vouch for my knowledge, maybe a couple that will say I’m full of crap. That will sort itself out in the next few weeks testing this bullet takes. The longer it takes, the more promise the bullet has.

All that said as a disclaimer, let the rat killing begin.

Order places in the morning, tracking number before lunch, bullets in hand in a couple of business days. Pretty good service I’d say.

Opening the box and enclosed was some load data, drop chart and drag curve. This is where the problems begin. The drag curve plots the G7 norm, a non existent bullet and the Aerospike. This was discussed in one of the threads. It is basically a pointless comparison.

Then there is the load data. Min and Max. charge weights, but no loaded length. This will become critical later.

A Quick Look at the bullets raises some other concerns.

The parting on the base, leaves them any thing but concentric or repeatable. Maybe with the new tail design, the steering end is not important as I have been led to believe. If these were cast bullets, they would go back in the pot. Sorry for the dirty fingers.

Then there is tip of the nose. You can feel 2-3 transitions to the tip. Honestly not sure if the tip is centered.

First check is in a chamber gauge. Since the gauge also checks overall length, first thing I do is confirm it can be loaded to magazine length or longer. This bullet, in this chamber will touch the lands around 2.320”. Nice to know for a bolt action, and that loading to SAAMI max is safe.

But can it really be loaded to that length?

Take a look at where the boat tail begins and neck in the chamber ends. It’s easier to see here, but the bearing surface is so short and so far back, that the bullet is out of the case, before the ogive contacts the lands.m

So if you want a jam, and load from a magazine, it’s off the table. Not a deal killer, but…..

My brass is trimmed to 1.365”, .003” off max.this bullet will have minimum .060-.080” jump, before you seat the bullet in the neck depending on your trim length.

Easier to see with brass in the gauge.

The jump will already be .050”+, that will only grow as you begin to seat the bullet. I hope these bullets like a long jump, because it will be .200-.300”. It’s just not practical in a AR to only have .125” of bearing surface in the neck giving you only .175-200” jump.

Again this is first glance, a lot of what I’ve flagged here can be worked around. If you have the experience of a few different cartridges and thousands of rounds with different bullets under your belt. But at first glance this bullet will be frustrating for a lot of people to load and shoot. It may also be dangerous for a few novice loaders.

The first thing that needs to be included in the load data is a maximum COAl. Not to include that is asking for trouble.

Hopefully this weekend I can load some up, honestly I’m a bit worried about spin rate. I think it will quite possible that at a spin rate approaching 300,000 rpm’s, that nose may just be a problem. Maybe it will balance out the base. Who knows.

Anyone know if you can hold A bullet manufacturer responsible for a baffle strike?

Over time I’ll try and run this bullet in every twist from 5-10 and velocities from 900-2400 fps. Probably will have some interesting feed back.

I hope this helps some other folks that may be working with or considering this bullet.

All that will really matter is what the targets show, but initial load might take some time. I will load to the manufacturer tested velocity first, then develop my own loads.