I am going to have a 6br built to shoot 105 Amax's using Lapua brass using a 28'Brux barrel. A friend offered me the use of his reamer & was wandering if someone could read the print for me & tell me if it will be suitable for my combination.I tried to attach the print but can't,however, I can email it or PM it to anyone that wishes to help. Thanks.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6br reamer specs. question

- Thread starter madmixerman

- Start date

If you'll email me the reamer print I'll have a look at it, and I'll try to post it here so others can see it, too.

Toby Bradshaw

baywingdb@comcast.net

Toby Bradshaw

baywingdb@comcast.net

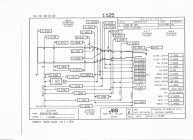

Here's the reamer print. The freebore is 0.116, which looks perfect for the 105 A-Max. This should put the base end of the bullet bearing surface,the heel) just above the neck-shoulder junction with the bullet touching the lands.

Toby Bradshaw

baywingdb@comcast.net

Toby Bradshaw

baywingdb@comcast.net

Attachments

Thanks Toby. BTW,my Lapua brass says 6br Norma on it & this print says 6 br Remington. Does that pose any problems?

I'm not sure why your reamer print says Rem instead of Norma, since the diameter at 0.200 above the base,0.4714), and the overall length,1.570) are right for the Norma but too fat/long for the Rem. I.e., your 'Rem' reamer is cutting a chamber appropriate for Lapua 6BR Norma brass and 105-108gr bullets. [BTW, nominal length for the 6BR Norma case is 1.560, so most reamers that I've seen are 1.565 to give 0.005 clearance for max-length cases. My Lapua brass is very close to 1.555 out of the box, so you'll have a little extra room past the case mouth.]

Oh, and note that the neck on your reamer is tapered from 0.272 at the shoulder to 0.271 at the mouth. That 0.271 could be cutting it close if you use a 'fat' bullet,some flat-base bullets can be 0.2433-0.2435 in the shank-pressure ring). You might get your smith to make you a neck gauge from a piece of barrel stub when he chambers the barrel. This gauge will help you set up initial bullet seating depth as well as serving as a safety check on loaded round neck dimension. Keep those necks clean.

Toby Bradshaw

baywingdb@comcast.net

Oh, and note that the neck on your reamer is tapered from 0.272 at the shoulder to 0.271 at the mouth. That 0.271 could be cutting it close if you use a 'fat' bullet,some flat-base bullets can be 0.2433-0.2435 in the shank-pressure ring). You might get your smith to make you a neck gauge from a piece of barrel stub when he chambers the barrel. This gauge will help you set up initial bullet seating depth as well as serving as a safety check on loaded round neck dimension. Keep those necks clean.

Toby Bradshaw

baywingdb@comcast.net

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.