You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

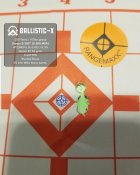

223 single digit S.D.

- Thread starter 6fatrat

- Start date

I would say that is outstanding.Drew

20 shots, 40 minutes, 2 strings.

Best I can do

Bob

About as good as anyone can get it I'm guessing. 85.5?

Ned Ludd

Silver $$ Contributor

N135 seems to work...uhhh...very well indeed. I never tried that with the 90s, but thought about it. What kind of barrel and feebore length do you need to hit 2925+ fps with 90 VLDs without killing the brass in a single firing? Or is that merely a benefit of using N135? If so, it's a remarkable powder in that particular combination. Nicely done!Lapua brass, Federal 205M, N135 and Berger 90 VLD

Have to believe that you are running 200+ freebore. There is a node around 2910 that I found back in the day with 8208xbr, but virgin Lapua brass' primer pocket did not survive. Congratulations for finding success there.30”

7 twist

I’m using my original lot of (1000) brass, (fired 9 and loaded 10). Just short of 900 left.

Bob

Ned Ludd

Silver $$ Contributor

Thanks for the details @rcgill. I have previously tested N140 under heavies in the .223 Rem. Velocities were similar to Varget on a charge weight basis, but I found the transition to "over-pressure" to be very abrupt with N140. Based on your results, the N135 powder seems to be better suited for this purpose.

It took me a few years and shooting every weekend and loading all week but I have been having great luck lately with 2 thousands neck tension, powders like n133, n140, power pro Varmint even got me a SD of 5 recently! And that one was a ball powder. I anneale every firing, and use an expander mandrel and Mighty Armory FL die. I seat primers 4 thousands below flush with 21st century. I can say that at least 70% of the time I can get a SD of 10 or less, but it's not as easy as a 308 case forsure. Both Starline and Lapua brass is what I been using lately. I seat with a redding micrometer and use the Short Action customs bullet comparitor. 2 thousands shoulder bump. Barrels are WOA and Shilen service rifle. This most recent group was 4 shots with a 5SD with a ball powder Powder Pro Varmint and 55 grain nosler BT. I know my techniques are working but sometimes I will get a higher SD but tiny groups so I don't obsess over that anymore just group size with 223.

Attachments

Jeff Porter

Gold $$ Contributor

Now you are just showing off Bob. Is that your Palma load ?

Edit - ok I saw the later post.

Edit - ok I saw the later post.

CharlieNC

Gold $$ Contributor

Respectfully I would say you have the process backwards, ie develop a good load based on the target and then check the Chrono if necessary. Using measures of variability such as Chrono SD and target group size are fraught with a high degree of uncertainty, which must be considered and accounted for when planning an evaluation vs just looking at a result in isolation and deeming it satisfactory.

Yes I know but my lack of health today prevented me from putting up a target so I was only able to crony the loads .Respectfully I would say you have the process backwards, ie develop a good load based on the target and then check the Chrono if necessary. Using measures of variability such as Chrono SD and target group size are fraught with a high degree of uncertainty, which must be considered and accounted for when planning an evaluation vs just looking at a result in isolation and deeming it satisfactory.

But even with the magneto speed bayonet fixed to the barrel I was able to blow up 6 cowturds in a row ranging from 380 to 420 yards

At least I have a speed to work with .

Ned Ludd

Silver $$ Contributor

Respectfully, there are numerous top F-Class shooters that would disagree with you. Due to the long strings of fire in F-Class matches, minimizing velocity variance is a critical step in load development, which is why they pay such close attention to ES/SD values during load development. That is also why testing different primers has become more commonplace amongst F-Class shooters. Tuning group size using seating depth is a relatively simple task once combustion (powder, charge weight, primer, etc.) has been optimized for a given load, and acceptably low ES/SD achieved. I understand the statistical limitations of using a relatively small sample size. The ES/SD values for small sample sizes can be associated with a large degree of uncertainty, and in any event, ES/SD will almost always increase as the number of shots increases. To a large degree, those issues can be overcome by sufficient testing and load validation.Respectfully I would say you have the process backwards, ie develop a good load based on the target and then check the Chrono if necessary. Using measures of variability such as Chrono SD and target group size are fraught with a high degree of uncertainty, which must be considered and accounted for when planning an evaluation vs just looking at a result in isolation and deeming it satisfactory.

A load with excessively high ES/SD values will usually come back to bite you in a match at 1000 yd, regardless of how well it shoots at shorter distances during load development. Dropped points "out the corners" is usually the result. Not many F-Class shooters have the opportunity to regularly develop loads at 1000 yd; 100 to 300 yd is more typical. If one carries out load development at shorter distances without recording chronograph data during the process, only to find unacceptably high ES/SD at the very end with a load they thought looked great on the target, then they are back to square one. It requires only minimal effort to record velocity measurements during the load development process. Whether one chooses to actually use the velocity data as an integral part of the process or not, it can't be used if it isn't recorded.

CharlieNC

Gold $$ Contributor

I have not as yet found a load which yielded a stable point of imact across a decent charge weight range during ladder testing, which suffered from velocity variability both within a match or across seasons of the year. While the velocity deviations are quite different during ladder testing, the velocity effects can be mitigated by positive compensation. On the other hand, such a node developed at "short" range will not necessarily hold up at "longer" range because their ballistic drops are quite different vs the part of the harmonic cycle which was chosen. Of course there is a point where the effect of excessive velocity variability cannnot be overcome with harmonics, just like the "wrong" bullet won't shoot.Respectfully, there are numerous top F-Class shooters that would disagree with you. Due to the long strings of fire in F-Class matches, minimizing velocity variance is a critical step in load development, which is why they pay such close attention to ES/SD values during load development. That is also why testing different primers has become more commonplace amongst F-Class shooters. Tuning group size using seating depth is a relatively simple task once combustion (powder, charge weight, primer, etc.) has been optimized for a given load, and acceptably low ES/SD achieved. I understand the statistical limitations of using a relatively small sample size. The ES/SD values for small sample sizes can be associated with a large degree of uncertainty, and in any event, ES/SD will almost always increase as the number of shots increases. To a large degree, those issues can be overcome by sufficient testing and load validation.

A load with excessively high ES/SD values will usually come back to bite you in a match at 1000 yd, regardless of how well it shoots at shorter distances during load development. Dropped points "out the corners" is usually the result. Not many F-Class shooters have the opportunity to regularly develop loads at 1000 yd; 100 to 300 yd is more typical. If one carries out load development at shorter distances without recording chronograph data during the process, only to find unacceptably high ES/SD at the very end with a load they thought looked great on the target, then they are back to square one. It requires only minimal effort to record velocity measurements during the load development process. Whether one chooses to actually use the velocity data as an integral part of the process or not, it can't be used if it isn't recorded.

Regarding the statistical reliability of the results, it is quite reasonable to use the SD of 5 shots and examine the trend with charge weight or seating depth and if there is a clear correlation then use that result. Conversely shooting loads which do not vary in some systematic matter, and simply choosing the one which has the "lowest" SD is where sample size is a big deal and it is easy to draw a false conclusion.

Plenty of room on velocity to spare Bob! Cool to see

Similar threads

- Replies

- 5

- Views

- 1,282

- Replies

- 38

- Views

- 5,449

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.