The real key is to carry out some velocity testing with relatively small number of cases to determine exactly how much internal volume variance you can get away with before the velocity change becomes significant. The easiest way to do this is to select 5 cases (each) with the highest and lowest volumes you can from a given brass prep, load them up identically, then determine velocity. For this experiment, it's better to use actual case volume, but I would also weigh the cases prior to loading. As the total number of cases required is small, it shouldn't be too painful. Once you have determined velocities, you can decide for yourself how much internal volume variance you can really stand, and how to achieve that level of volume variance. IMO - chances are pretty good you can come very close to doing it simply by weight-sorting the cases into 3 to 5 distinct groups.

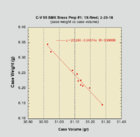

The data in the graph below is derived the exact same brass prep for which I showed the effect of case weight on velocity earlier in this thread. Notice the two cases of weight greater than 6.30g at the upper left. Those are from the same "heavy" subgroup that represents about one in 4 cases within this Lot of brass and gave me almost 30 fps greater velocity than the three cases in the 6.17 to 6.22 gr weight range. Sorting 150 cases (or more) by weight can easily be done in less than an hour using an analytical balance, which many also use to weigh powder.

View attachment 1098249