No manches"

Gold $$ Contributor

Wow!..

Very intriguing..surprised to say the least

Last edited:

Wow!..

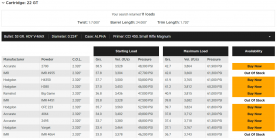

charge is 37.2 gr of 8208xbr coal is 2.31 (1.865 to ogive) Case capacity of a new GAP (hdy) 6 GT case necked to 22 is 44.1gr. H2O. 450 primers look good, no heavy bolt lift.Sounds a little too hot?

Just for reference, here is the Hodgdon online data for 22 GT at 24" with a variety of powders and pressures using Alpha brass and we would take a little more speed off of these numbers at 22"

View attachment 1661320

If it were my friend, I would back way down.

The 53 VMax is a pretty good bullet for it's weight, so it will do fine even below the velocity in the Hodgdon 24" bbl chart.

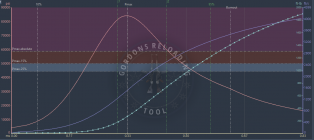

He would be looking at roughly 3680 fps for a typical 22 GT with 22" and a 53 VMax to be roughly 61.3 ksi. He is at 4014, so he is running more than 62 KSI.

Be happy to run a model estimate for them if they like, would need their COAL and case volume with their powder and charge.

charge is 37.2 gr of 8208xbr coal is 2.31 (1.865 to ogive) Case capacity of a new GAP (hdy) 6 GT case necked to 22 is 44.1gr. H2O. 450 primers look good, no heavy bolt lift.

Running this in Gordon’s?

The hodgdon data was a 1-7T this is a 12T. Could that help soften the pressure?

I weighed these, filling each the same with a syringe and water. The Alpha is 44.2gr of H20 once fired. The Hornady new and sized to 22 is 44.1. So not much difference. The primer pockets on the alpha are tighter so they should handle pressure longer.The faster the twist, the sooner it will pressure out. Or more correctly, the slower the bullet will go at the same charge. I know that for a fact.

Two totally different kinds of brass. My guess is that Alpha is smaller.

No, the twist doesn't account for this. I will just beg you to stop and inspect everything. Something is way off.charge is 37.2 gr of 8208xbr coal is 2.31 (1.865 to ogive) Case capacity of a new GAP (hdy) 6 GT case necked to 22 is 44.1gr. H2O. 450 primers look good, no heavy bolt lift.

Running this in Gordon’s?

The hodgdon data was a 1-7T this is a 12T. Could that help soften the pressure?

I will back it down, It was working quite well with alpha brass. You might go back and read through this thread, as there are other folks saying they are seeing 3950ish with 50-55gr in this UrbanBrad 12T barrel.No, the twist doesn't account for this. I will just beg you to stop and inspect everything. Something is way off.

After I stopped and thought about it for a second, I realized how crazy high the pressure must be to account for the speed.

If we take things at face value for muzzle energy, they are potentially very dangerous.

That you got 4000 fps, and also report the brass and primers don't show signs, means something is not making sense.

The only way a 53 grain bullet in a 22" bbl gets to over 4000 fps in a 22GT, is with enough pressure to account for that muzzle energy.

In back of the envelope terms, you would be way over pressure to get a muzzle energy of 2571 Joules (1896 Ft*Lbs) For that to be explained by a typical pressure pulse, your pressure would be in the neighborhood of 82 ksi. Brass is usually run well below 65 ksi and is going to flow above 70 ksi.

A typical 22 GT would give you something like 2161 Joules or 1594 ft*lbs with a pressure peak of 62 ksi. Your energy level is 2571/2161 = 119% or 19 % higher than normal.

Do a sanity check on everything and lets hope the chronograph was wonky.

I will back it down, It was working quite well with alpha brass. You might go back and read through this thread, as there are other folks saying they are seeing 3950ish with 50-55gr in this UrbanBrad 12T barrel.

I will back it down, It was working quite well with alpha brass. You might go back and read through this thread, as there are other folks saying they are seeing 3950ish with 50-55gr in this UrbanBrad 12T barrel.

RangeRat I do appreciate your feedback on this. I had not seen any data on 8208xbr in the 22 GT so I ran very conservative test loads from 35gr on up .3 gr apart. When I reached the speeds I had seen using Varget I quit. This was all in alpha brass with 53gr Vmax. Pressure signs to me are flattened primers, firing pin dimples and any increase in bolt lift. The Alpha brass and SR cci 450 primers could very well sustain pressures above wise numbers. Three times through a few pieces of brass and I don’t feel any loosening of primer pockets.I am just as guilty as anyone when it comes to pushing pressure into the redline on my varmint rigs.

(However, I can also measure my pressure and analyze my design margin to make sure it is understood before I proceed.)

If the chamber and brass get along, you can run hotter than industry safety standards would recommend but just make sure you know what you have so you understand the risks.

Very few folks know the burst pressure of their rigs or their brass, nor do they understand how we margin those issues when weapon systems are designed.

I'm not trying to be the fun police by any means but just giving you a qualified perspective just in case you didn't realize how hot you are running.

If it shoots like that, I would just double check everything and that the rig is happy. That is going to put the hurt on them, and they won't know what hit them. In for the range reports.