Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sorting by empty case weight?

- Thread starter JeffG

- Start date

Wild Bill IV

Gold $$ Contributor

I'll throw a scenario out with that 1.25 MOA at 200. Your climbing a hill got some cross wind, breathing going on a good buck jumps up in front of you and now you got a little buck fever going on now whats your 1.25 MOA like you had at the range?

Or a buck or bull of a lifetime presents itself at 400 now is that 1.25 MOA with the above conditions now what do you do with your 1.25 MOA gun?

These minute of deer guns are never that in hunting conditions there not the same as at the range.

I agree!!! Getting yourself worked up before a shot is not like shooting at the range!!!

However, if you do your scouting early, you don't have to stalk and/or flush your trophy!!! Look for the opens and beanfield shoot (sniper) your prey!!!! I have several nice racks in the house!!! You have to work long before the season to be able to take down the big ones with ONE COLD BARREL SHOT!!!!

I see your point for out of state hunts!!! They are tough!!! Getting in shape and practicing a lot is essential for filling that type of tag!!!

Shooting the sage rats with that hunting rifle in the off season can aid in reducing the buck fever heartbeat and tune the shooter to the full capability of the rifle/loads (learning the minutes of deer)!!! It also helps the shooter learn windage, elevation, and ranging corrections (firing solutions) for the rifle!!

Plus, a hunter needs to learn to control the heartbeat rate!!! I work on that while watching TV and playing with the finger clamp monitor!!! Learn to get the rate down to 40 beats/min!!! Go on a low sodium diet (1200-1600mg of sodium/day) about a month before the season will allow the hunter to control his heartbeat by lowering the blood pressure!!!! Mine is 120/85 at age 69!!!

I'm an old BEANFIELD SHOOTER with tuned rifles and loads that shoot less than 0.5MOA!!! That once in a lifetime bull is going down at 400!!! That heart is about 4 inches, with the rifle capable of shooting 2in at 400, that leaves twice the human error!!! HE GOING DOWN!!! The rapid heart beat (buck fever) is easier to control in my older, and more experience body now!!!

Last edited:

Thanks for taking the time to share real data. My “assumption” has been that weight variation could be attributed to differences in the case head or other areas that would not impact volume.I've measured case weights and volumes using plugs; no statistical difference. i.e. the spent primer weight-to-weight variation is statistically insignificant.

Here are my plots showing the trend line and the "R-Squared". The R-Squared is a statistical calculation that determines how good the data correlates. A value of 1.0 is a perfect correlation and 0.0 means there's absolutely no correlation. For reference, in soft sciences like social sciences, a value of 0.2 - 0.4 is considered good. In pure sciences, a value of 0.6 is considered good. The R-Squared results I got are too small to indicate any correlations between case + spent primer weight and case capacity.

I have a lot more data, including on Nosler cases, but it all led me down the same pathway...........there isn't a statistical correlation between weights and capacities.

View attachment 1685827

View attachment 1685828

View attachment 1685829

Your data actually shows a pretty good correlation between weight and internal volume. R-squared is interpreted as the amount of variation in the output that can be explained by variation n the input. Here (for 223 ) your data suggests that over 45% of the variation in volume can be attributed to case weight variation… statistically, that is pretty solid. However, the real question is, “is the observed variation in case capacity practically significant?”

CharlieNC

Gold $$ Contributor

If you take the time to weigh the brass to at least assure there are no outliers, then you will know the degree of variability as well. Since you have then invested 95% of the time required, why would you not segregate them if there is >1gr variability. Especially if you are a .02gr powder charge accuracy type of guy.Thanks for taking the time to share real data. My “assumption” has been that weight variation could be attributed to differences in the case head or other areas that would not impact volume.

Your data actually shows a pretty good correlation between weight and internal volume. R-squared is interpreted as the amount of variation in the output that can be explained by variation n the input. Here (for 223 ) your data suggests that over 45% of the variation in volume can be attributed to case weight variation… statistically, that is pretty solid. However, the real question is, “is the observed variation in case capacity practically significant?”

222Jim

Silver $$ Contributor

Is the observed variation practically significant? Good question @cdgaydosThanks for taking the time to share real data. My “assumption” has been that weight variation could be attributed to differences in the case head or other areas that would not impact volume.

Your data actually shows a pretty good correlation between weight and internal volume. R-squared is interpreted as the amount of variation in the output that can be explained by variation n the input. Here (for 223 ) your data suggests that over 45% of the variation in volume can be attributed to case weight variation… statistically, that is pretty solid. However, the real question is, “is the observed variation in case capacity practically significant?”

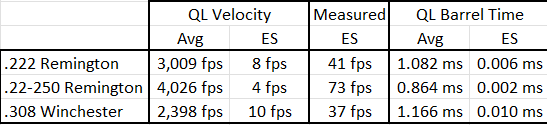

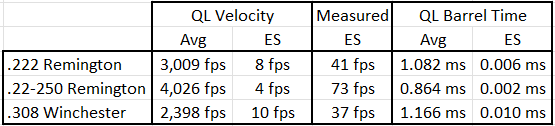

My simple answer is "not really". The basis for that is how much of the measured velocity variation would be based on case weights IF case capacities perfectly correlated with case weights, i.e. the slope of the regression line on those charts has an R-Squared of 1.0. How I worked out the math was:

- I took the average case weights +/- 2 stand deviations, which covers 95% of expected results, and

- Used the slope of the regression line to estimate the implied change in case capacities, then

- Determined the change in velocity (and barrel time) using my tuned version of QuickLoad (QL):

Given how small the velocity impact is between the extremes of +2 standard deviations to -2 standard deviations, I couldn't justify weight sorting cases.

I threw in barrel time because many people use it too......the calculated change in barrel time is also negligible.

Jim

Attachments

Last edited:

When do you weigh cases? Should it be done on new brass or can it be done on fired brass?

ELR LVR

Silver $$ Contributor

"Don't practice missing"I appreciate all your suggestions about "practical" precision, all very true and practiced in my non-competitive experience too.

And to qualify my latent obsession with precision in my reloading practices, it comes from my also-latent practical shooting practice of; "aim small = miss small" , and "DON'T practice missing" .

These on-line discussions help me focus, slow my heart rate and breathing, and give me time to reconsider my target, before I pull the trigger,

---I like that

That goes along with 2 of my motto's

"Aim small, and DON'T miss"

"Dont practice until you finally get it right,... practice until you can no longer get it wrong"

------------------------------------------------

There is a lot that goes into the psychology of the Human Brain

Power of suggestion is very powerful, Psyching yourself up to do good for instance ...works

The idea of allowing yourself to miss small, is still missing

You may think I am being hard, No, I am hard on myself

I am demanding of myself

And I know the results of that

---------------------------------------------------

a Self induced prophecy of "missing" will be the result of thinking

"Aim small miss small"

Instead keep telling yourself

"Aim small, and DON'T miss"

-----------------------------------------------------

It's kind of like the difference of saying to yourself

"I'll try" vs. "I will"

Last edited:

222Jim

Silver $$ Contributor

I only weigh cases as part of the process of calculating their capacity, and that's best done once they have been fired and have grown to fit your rifle's chamber.When do you weigh cases? Should it be done on new brass or can it be done on fired brass?

ELR LVR

Silver $$ Contributor

BTW, this is how I now sort my brass

It doesn't matter what it weighs, or how far apart they are from each other

This lot of brass was 22 BR.... Approx 127 to 132 grains weight

all up to 5 grains apart, but puts them all into the same hole (all that matters)

-----------------

As long as it puts them all into the same hole

I don't care

When I test now, the brass that shot like this....gets lumped together with the brass that did exactly the same thing, regardless of weight, brand, length, neck thickness etc

Makes more sense to me to sort them according to how they actually perform on target

than how much Juju I massaged into them on the reloading bench

It doesn't matter what it weighs, or how far apart they are from each other

This lot of brass was 22 BR.... Approx 127 to 132 grains weight

all up to 5 grains apart, but puts them all into the same hole (all that matters)

-----------------

As long as it puts them all into the same hole

I don't care

When I test now, the brass that shot like this....gets lumped together with the brass that did exactly the same thing, regardless of weight, brand, length, neck thickness etc

Makes more sense to me to sort them according to how they actually perform on target

than how much Juju I massaged into them on the reloading bench

Attachments

ELR LVR

Silver $$ Contributor

Why?

Because I have also weight sorted brass to all be exactly the same

yet shoot like this

which for me, is unacceptable unless it's a hunting, varmint or factory rifle

then it's pretty dang decent, but not really something to boast about

so why weight sort brass if it wont shoot better than this?

So yeah, I sort according to test results instead of weight

It used to make me "Feel" better weighing them, until I realized some would still shoot different for some reason which cannot be explained. While others that varied, would still hold within the group.

So now I think it's about as useful of an exercise as cleaning primer pockets

(I will cull out any brass that are extreme outliers though)

For the most part I will sort it into 3 groups, Light, Medium, Heavy

Because I have also weight sorted brass to all be exactly the same

yet shoot like this

which for me, is unacceptable unless it's a hunting, varmint or factory rifle

then it's pretty dang decent, but not really something to boast about

so why weight sort brass if it wont shoot better than this?

So yeah, I sort according to test results instead of weight

It used to make me "Feel" better weighing them, until I realized some would still shoot different for some reason which cannot be explained. While others that varied, would still hold within the group.

So now I think it's about as useful of an exercise as cleaning primer pockets

(I will cull out any brass that are extreme outliers though)

For the most part I will sort it into 3 groups, Light, Medium, Heavy

Attachments

Last edited:

As soon as a guy thinks he has this figured out, something will change.

Some days I see a correlation between weight and speed then I don’t and then it’s back again.

Today I shot some lighter weight brass with a load from last weekend and not only did they run 40 fps slower they also impacted a minute low on the target.

It makes my head hurt. Lol

Jim

Some days I see a correlation between weight and speed then I don’t and then it’s back again.

Today I shot some lighter weight brass with a load from last weekend and not only did they run 40 fps slower they also impacted a minute low on the target.

It makes my head hurt. Lol

Jim

I’ve been sorting by weight, H2O volume and now I’m using the Bison Armory Volume Gauge to periodically check my case capacity looking for an occasional outlier

There’s a slight learning curve to get consistent results with this tool but once you figure it out it’s the quickest and most reliable method I’ve tried so far

There’s a slight learning curve to get consistent results with this tool but once you figure it out it’s the quickest and most reliable method I’ve tried so far

222Jim

Silver $$ Contributor

Nice! Results look good and it's got to be faster than the standard "weigh, add water, weigh again" that most of us use.I’ve been sorting by weight, H2O volume and now I’m using the Bison Armory Volume Gauge to periodically check my case capacity looking for an occasional outlier

There’s a slight learning curve to get consistent results with this tool but once you figure it out it’s the quickest and most reliable method I’ve tried so far

View attachment 1686319

View attachment 1686320View attachment 1686321

Sadly I went to their website and saw they had to increase their price from $199 to $299. Why? Their electronics are imported from China and now include a hefty tariff.

Mark , you have the best toys by far …I’ve been sorting by weight, H2O volume and now I’m using the Bison Armory Volume Gauge to periodically check my case capacity looking for an occasional outlier

There’s a slight learning curve to get consistent results with this tool but once you figure it out it’s the quickest and most reliable method I’ve tried so far

View attachment 1686319

View attachment 1686320View attachment 1686321

So my question is , in a 100 box of Lapua 6br brass how many outliers do you usually find ?

Last edited:

Jim, I like nice toys and don't mind the $$ IF I can shrink my agg just a little bit

I ran 250 BRA cases getting ready for the Rendezvous and haven't found any outliers that I had to scrap but I take my brass prep to OCD level X 10 and I think that might help with consistency

I ran 250 BRA cases getting ready for the Rendezvous and haven't found any outliers that I had to scrap but I take my brass prep to OCD level X 10 and I think that might help with consistency

My primary interest is ELR and when TOFs are several seconds, differences in velocity really show up.

I set up the Bison case volume tool with a pneumatic drive and used a 21st century plug turned to match the bottom of a shell holder. I'm satisfied with the Bison tool, but as mentioned above, there is a learning curve and there are limitations.

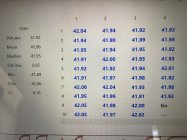

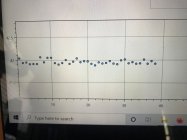

The test results below are a bad case of TMI. The cases are 33XC that had been fired once in a seasoned barrel. New cases have volume differences that are relics from the manufacturing process. Fired cases can be much more uniform in volume if the pressure histories are the same. That excludes brass used for pressure ladders or the early stages of barrel break in. Some differences in pressure history can be covered up with sizing, but all of the cases must need sizing and none of them can have significantly more spring back than the others.

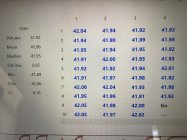

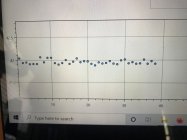

I used the 5 heaviest and 5 lightest cases in the lot. Each case volume was tested 10 times to estimate the repeatability of the measurement. The case number is the horizontal axis, the test count are the series. The Bison tool is designed for much smaller cases. I used a steel dowel with 52 grains of volume to bring the case volume down into a range nearer what the tool was designed for. The tool has a warmup period. My thoughts are both the extra volume and steel dowel extended that.

There is a lot of noise, but the case volume tracks the case weight to a significant degree.

This is the raw data.

If the differences were entirely the result of things above the extractor groove, the weight and volume would be related by the specific gravity of cartridge brass. That's 8.5, giving a volume difference of 0.35 grains of water for a weight difference of 3 grains. Comparing the weight and volume differences between the 5 heaviest and 5 lightest cases and averaging through the noise, the measured volume estimate comes out to 0.31. That's not a bad match. The rest of the story is the problem is on the volume measurement side of the comparison. The difference in volume measurements on an individual case is larger than the difference between cases. The results are pretty consistent for 10 cases but the temperature drift would catch up to you if you tried to measure 100 cases this large.

That 0.3 grains of water capacity works out to 3 fps in QL. If the ES is estimated at 20 fps from 4X an SD of 5 fps and we eliminate that 3 fps, the new ES isn't 17. A better estimate would be:

(20^2-3^2)^0.5 =19.8 fps

So no, you won't see it.

This is an extreme example. A heavy, high volume case from boutique manufacturer in a set that was weight sorted from a larger batch.

I can sort brass on weight at a sustained rate of ~5 per minute. With new brass, checking the volume isn't really an option. Even using water and fired brass, the volume estimates vary by almost half a grain on an individual case this large. Sorting by weight isn't a bad option.

A trick for sorting brass by weight quickly is to try a few and find one with a median value. Zero the scale with that case and set it aside to check drift as you go. I have a strip of masking tape in front of the scale marked -2, -1, 0, 1, 2. They're separated by enough to fit 10 cases between them. Drop a case on the scale and set the case down on the bench at the appropriate point on the tape. No math, no thinking, fewer errors. 100 cases in about 20 minutes. Do it the first time and be done with it.

The color of the box the brass is shipped in won't save you. My first box of 300PRC that came in a blue box only had 99 cases in it. The first 10 cases I measured were 7 grains apart. Hornady has been running 2.5-3 grains. ADG is below 2.

I set up the Bison case volume tool with a pneumatic drive and used a 21st century plug turned to match the bottom of a shell holder. I'm satisfied with the Bison tool, but as mentioned above, there is a learning curve and there are limitations.

The test results below are a bad case of TMI. The cases are 33XC that had been fired once in a seasoned barrel. New cases have volume differences that are relics from the manufacturing process. Fired cases can be much more uniform in volume if the pressure histories are the same. That excludes brass used for pressure ladders or the early stages of barrel break in. Some differences in pressure history can be covered up with sizing, but all of the cases must need sizing and none of them can have significantly more spring back than the others.

I used the 5 heaviest and 5 lightest cases in the lot. Each case volume was tested 10 times to estimate the repeatability of the measurement. The case number is the horizontal axis, the test count are the series. The Bison tool is designed for much smaller cases. I used a steel dowel with 52 grains of volume to bring the case volume down into a range nearer what the tool was designed for. The tool has a warmup period. My thoughts are both the extra volume and steel dowel extended that.

There is a lot of noise, but the case volume tracks the case weight to a significant degree.

This is the raw data.

If the differences were entirely the result of things above the extractor groove, the weight and volume would be related by the specific gravity of cartridge brass. That's 8.5, giving a volume difference of 0.35 grains of water for a weight difference of 3 grains. Comparing the weight and volume differences between the 5 heaviest and 5 lightest cases and averaging through the noise, the measured volume estimate comes out to 0.31. That's not a bad match. The rest of the story is the problem is on the volume measurement side of the comparison. The difference in volume measurements on an individual case is larger than the difference between cases. The results are pretty consistent for 10 cases but the temperature drift would catch up to you if you tried to measure 100 cases this large.

That 0.3 grains of water capacity works out to 3 fps in QL. If the ES is estimated at 20 fps from 4X an SD of 5 fps and we eliminate that 3 fps, the new ES isn't 17. A better estimate would be:

(20^2-3^2)^0.5 =19.8 fps

So no, you won't see it.

This is an extreme example. A heavy, high volume case from boutique manufacturer in a set that was weight sorted from a larger batch.

I can sort brass on weight at a sustained rate of ~5 per minute. With new brass, checking the volume isn't really an option. Even using water and fired brass, the volume estimates vary by almost half a grain on an individual case this large. Sorting by weight isn't a bad option.

A trick for sorting brass by weight quickly is to try a few and find one with a median value. Zero the scale with that case and set it aside to check drift as you go. I have a strip of masking tape in front of the scale marked -2, -1, 0, 1, 2. They're separated by enough to fit 10 cases between them. Drop a case on the scale and set the case down on the bench at the appropriate point on the tape. No math, no thinking, fewer errors. 100 cases in about 20 minutes. Do it the first time and be done with it.

The color of the box the brass is shipped in won't save you. My first box of 300PRC that came in a blue box only had 99 cases in it. The first 10 cases I measured were 7 grains apart. Hornady has been running 2.5-3 grains. ADG is below 2.

Only the dashed black case weight series uses the secondary, case weight, axis. The rest use the primary, volume axis. The step from the 5 lightest to the 5 heaviest is obvious.

Top to bottom along a given case number is the same case being measured 10X. It shows the temperature drift.

Left to right are strings of case measurements with different cases. It shows the case to case variation in volume.

Cases 1 through 10 were measured.

Then they were measured again until all of them had been measured 10X to see where the temperature drift stopped.

Top to bottom along a given case number is the same case being measured 10X. It shows the temperature drift.

Left to right are strings of case measurements with different cases. It shows the case to case variation in volume.

Cases 1 through 10 were measured.

Then they were measured again until all of them had been measured 10X to see where the temperature drift stopped.

6BRA

Gold $$ Contributor

From my use with this, so far 2 things effect the volumizer.I’ve been sorting by weight, H2O volume and now I’m using the Bison Armory Volume Gauge to periodically check my case capacity looking for an occasional outlier

There’s a slight learning curve to get consistent results with this tool but once you figure it out it’s the quickest and most reliable method I’ve tried so far

View attachment 1686319

View attachment 1686320View attachment 1686321

Your pull on the press handle must be very consistent..but even more so, you must be in a pressure stable room. If the AC or Heat is running it seems to have variance when it kicks on/off.

I may have come to the conclusion if you are able to reload to tight tolerances, the Garmin chrono is a better culling tool.

I agree, that's why I use this tool with my Prazi Press which is super smooth, I also wear a thin cotton glove to make sure I don't affect the temp by handling cases and I have a small fan blowing ambient air over cases I'm measuring.

As far as Garmin is concerned IMO it takes the entire loading process into equation like brass prep, neck tension, powder charge and primer where the Bison Gauge is measuring just the case volume allowing you to eliminate one inconsistency at a time, I weigh primers I use AMP press to eliminate neck tension variance and test neck tension with several different bushings during load development trying to leave no stone unturned

As far as Garmin is concerned IMO it takes the entire loading process into equation like brass prep, neck tension, powder charge and primer where the Bison Gauge is measuring just the case volume allowing you to eliminate one inconsistency at a time, I weigh primers I use AMP press to eliminate neck tension variance and test neck tension with several different bushings during load development trying to leave no stone unturned

Similar threads

- Replies

- 20

- Views

- 2,327

- Replies

- 67

- Views

- 8,974

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.