L.Sherm

Silver $$ Contributor

Exactly same as bullet the correct?Sir, The final lap goes in and out.

Exactly same as bullet the correct?Sir, The final lap goes in and out.

So when the bullet gets to the muzzle it follows the lap back to the chamber? I wasn't aware of that.Exactly same as bullet the correct?

OMG Butch let sleeping dogs lie.So when the bullet gets to the muzzle it follows the lap back to the chamber? I wasn't aware of that.

I'm sorry I stepped on your toes young man. I don't believe that I even knew that you did rifle work, so I had no reason to doubt your ability. So, do you mfg button or cut rifle barrels?OMG Butch let sleeping dogs lie.

How many barrels you made that have won the SWN?

Here is an example of messages ove got on barrels ive made, ill let results speak for my methods.

I'm done with this

You have a PM.They were button Butch. I'm not here to debate processes i did alot of testing on lapping, heat treating, barrel steel etc.

Unfortunately to continue what I had going the owner made promises that weren't kept so I left.

Theres a very small handful that know what I did and I kept it that way all the way upto today its why I edited what I did

not looking for pats on the back.

All I cared about was results what a couple good shooters could tell me if I was doing what my test results told me I was. If a barrel maker thinks its an advantage for them to not lap then do it my tests said otherwise. At the end of the day the target is what matter thats it.

I waited 10 weeks and received my barreled action back earlier than expected. The outside looked great. The inside looked like something from a civil war machine shop that had humidity problems. The chamber looked like chips got stuck in the chambering process and boogered up the chamber walls (forget about trying to reload good brass that came out of that chamber!) and the rifling looked really bad. Rusted and rounded lands edges that reminded me of a hack saw blade. I thought it would clean up with a good cleaning. Being a brand new barrel I tried cleaning it out with WD-40...no help...then tried Hoppe's...no help...then tried Wipe-Out (over night)...no help. Finally resorted to JB Bore polish...virtually no difference!!! THIS IS A BRAND NEW BARREL???!!! Sent it back to PBB and their response was that "the barrel was not lapped" and both the customer service rep and owners examined it and both "have no issues with this barrel". Got a full refund but lost my summer shooting and respect for PBB which for me now stands for "Pretty Bad Barrels". The "finished" product I received was the worst I've ever seen...good thing I had a bore scope. I do NOT recommend PBB especially if this POS has "no issues" per their staff and owners. Photos available upon request.https://preferredbarrelblanks.com/ Anyone ever use their barrels ? there lead time is 3 weeks . so you don't have to wait 8 months .

Didn't you post about buying a "307 ratherby" from PTG? Talk about unproven! I kid of course, id opt for a proven blank, and I agree I wouldn't use one over a Krieger, Bart, brux etc, but I feel there are enough reviews out there that prove the PBB barrels are shooters and completely acceptable for PRS and non competition shooting. Guys over on the hide are quite fond of them.$350 for a lapped, contoured barrel blank?? I think not. No twist slower than 10 in 243?

Sorry, I will opt for a proven blank even waiting on one.

The ratherby has been shipped and I'm waiting on a CM 22 cal blank from Shilen. I have an H&S stock and Shilen trigger are waiting on the barrel blank. It will become a 223AI or a 222 Rem. Mag Ackley. I'm good on brass and vae dies.Didn't you post about buying a "307 ratherby" from PTG? Talk about unproven! I kid of course, id opt for a proven blank, and I agree I wouldn't use one over a Krieger, Bart, brux etc, but I feel there are enough reviews out there that prove the PBB barrels are shooters and completely acceptable for PRS and non competition shooting. Guys over on the hide are quite fond of them.

Nice! I ordered one too once I saw your post on it.The ratherby has been shipped and I'm waiting on a CM 22 cal blank from Shilen. I have an H&S stock and Shilen trigger are waiting on the barrel blank. It will become a 223AI or a 222 Rem. Mag Ackley. I'm good on brass and vae dies.

I waited 10 weeks and received my barreled action back earlier than expected. The outside looked great. The inside looked like something from a civil war machine shop that had humidity problems. The chamber looked like chips got stuck in the chambering process and boogered up the chamber walls (forget about trying to reload good brass that came out of that chamber!) and the rifling looked really bad. Rusted and rounded lands edges that reminded me of a hack saw blade. I thought it would clean up with a good cleaning. Being a brand new barrel I tried cleaning it out with WD-40...no help...then tried Hoppe's...no help...then tried Wipe-Out (over night)...no help. Finally resorted to JB Bore polish...virtually no difference!!! THIS IS A BRAND NEW BARREL???!!! Sent it back to PBB and their response was that "the barrel was not lapped" and both the customer service rep and owners examined it and both "have no issues with this barrel". Got a full refund but lost my summer shooting and respect for PBB which for me now stands for "Pretty Bad Barrels". The "finished" product I received was the worst I've ever seen...good thing I had a bore scope. I do NOT recommend PBB especially if this POS has "no issues" per their staff and owners. Photos available upon request.

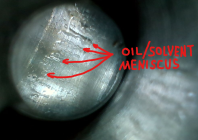

The first photo is the chamber and the next two are rifling after 2 days of cleaning with various cleaners including JB Bore Polish. I think I polished this "brand new barrel" from 6.5 to 7mm.Did you take any bore scope pics of the barrel?

Did you take any bore scope pics of the

I have this Cop buddy who believes "as long as bullets spit out the end of the barrel,The first photo is the chamber and the next two are rifling after 2 days of cleaning with various cleaners including JB Bore Polish. I think I polished this "brand new barrel" from 6.5 to 7mm.

Strike 1 was the rifling, strike 2 was the chamber, strike 3 was the response from PBB that there were no issues.