Wild Bill IV

Gold $$ Contributor

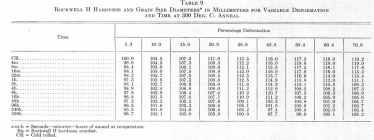

The link at the bottom has a chart shows the different hardness name (Dead Soft, Soft, Halve Hard, Hard, Extra Hard, and Spring Hard) and the Vickers Hardness (HV) ranges for the type of hardness Names for BRASS!!!!

OK YOU TWO!!! ELR VLR and Straightshooter1!!!!!!!!!

I recommend using a water bath 1st!!!!

Quench as soon as possible 2nd!!!!

Reasons below!!!!!

As Straightshooter1 has found, Lapau brass is, at the neck 100 HV (Half Hard)!

Go to the Norma Bullet home page, and scroll down an see their different grain structure and HV numbers, grain sizes and structured! In COLOR!!! This info below is from the Home Page!!!

IMO, the punched disk or slug is classified Dead Soft Brass with very large Crystalline grains!!!

1st draw cup: 69 HV, Large crystalline grain (lower Soft)

2nd draw cup: 81 HV, Large flattened grain (Soft)

Head of finished case: 190 HV very fine small grain (Spring hard)

Lower body: 170 HV a little large elongated crystalline grain (Extra Hard)

Neck: 120 HV large (Half Hard)

WOOOO! SPRING BRASS HARD IN THE HEAD!!! Everyone knows, you don't want heat on a spring!!!!!!! Unfortunately, we get heat from the fired round!!! Thank God the head only sees a few milliseconds of heat!!!! Try to avoid adding addition heat to the head/lower body which could change their properties some!!!

OK, 120HV (Norma neck) vs 100HV (Lapau neck)!!

Why the difference??? Norma's market is geared towards the hunter/shooter and has been around for a long time!!! Lapau's market is geared, mostly towards the COMP shooters now!!!

Rifle brass vs Target brass!!!!!!!!!!!!!!!!!

IMO, You could make Rifle brass into Target brass and maybe avoid CLICKERS!!!

I NEVER WANT TO HEAR THE TERM "SOFT" WHEN TALKING ABOUT BRASS AGAIN, UNLESS IT HAS AN ADJECTIVE IN FRONT OF THE TERM!!!!!!!

NOTE: Hard brass starts at 130HV!!! The start of possible neck slitting or cracking!!!!

www.bing.com

www.bing.com

OK YOU TWO!!! ELR VLR and Straightshooter1!!!!!!!!!

I recommend using a water bath 1st!!!!

Quench as soon as possible 2nd!!!!

Reasons below!!!!!

As Straightshooter1 has found, Lapau brass is, at the neck 100 HV (Half Hard)!

Go to the Norma Bullet home page, and scroll down an see their different grain structure and HV numbers, grain sizes and structured! In COLOR!!! This info below is from the Home Page!!!

IMO, the punched disk or slug is classified Dead Soft Brass with very large Crystalline grains!!!

1st draw cup: 69 HV, Large crystalline grain (lower Soft)

2nd draw cup: 81 HV, Large flattened grain (Soft)

Head of finished case: 190 HV very fine small grain (Spring hard)

Lower body: 170 HV a little large elongated crystalline grain (Extra Hard)

Neck: 120 HV large (Half Hard)

WOOOO! SPRING BRASS HARD IN THE HEAD!!! Everyone knows, you don't want heat on a spring!!!!!!! Unfortunately, we get heat from the fired round!!! Thank God the head only sees a few milliseconds of heat!!!! Try to avoid adding addition heat to the head/lower body which could change their properties some!!!

OK, 120HV (Norma neck) vs 100HV (Lapau neck)!!

Why the difference??? Norma's market is geared towards the hunter/shooter and has been around for a long time!!! Lapau's market is geared, mostly towards the COMP shooters now!!!

Rifle brass vs Target brass!!!!!!!!!!!!!!!!!

IMO, You could make Rifle brass into Target brass and maybe avoid CLICKERS!!!

I NEVER WANT TO HEAR THE TERM "SOFT" WHEN TALKING ABOUT BRASS AGAIN, UNLESS IT HAS AN ADJECTIVE IN FRONT OF THE TERM!!!!!!!

NOTE: Hard brass starts at 130HV!!! The start of possible neck slitting or cracking!!!!

Hardness of Brass - Bing

Intelligent search from Bing makes it easier to quickly find what you’re looking for and rewards you.

Last edited: