You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AMP vs Flame Group Sizes

- Thread starter rijndael

- Start date

There is a Youtube of Lou Merdica shooting in his tunnel.

It's covered here: https://www.ampannealing.com/articles/58/annealing-under-the-microscope/

Which is what sparked me to make this thread.

Thanks for this.It's covered here: https://www.ampannealing.com/articles/58/annealing-under-the-microscope/

Which is what sparked me to make this thread.

Don't forget to show us group size for each condition. All the numbers mean nothing if the groups are not small.i'm going to start a series with my new br dasher build on youtube. i think i'm going to break in the barrel by doing a bunch of random testing with annealing on some new alpha brass.

i was debating doing flame, but it would be something like this:

starting with all virgin brass, 3 cases in each set.

unannealed

amp annealed

flame annealed

after each firing, i will be recording group size, velocity, amp press graph force, shoulder bump, and neck spring back.

repeat this probably 5 times each

let me know if you all would like to see this done. i am open to any other ideas as well.

although I am excited to see, i'm not super concerned about group size for this test, i'm mainly concerned about obtaining the other metrics.Don't forget to show us group size for each condition. All the numbers mean nothing if the groups are not small.

i will be including group size as a serious metric, but according to the input from many members here, world class precision can be obtained either way.

I really want to see how consistent the amp keeps the brass and i want to use the amp as a baseline to see the effects of the cold working dynamics of the unannealed brass until it settles in.

for any of those wondering, the "test gun" is a drop port borden brmxd bedded and glued and screwed into a cerus XR stock, brux 7.83 twist 4 groove, alpha no turn reamer (0.120 fb), nightforce comp scope, berger 105 hybrids, 21st century front rest, dr flat top rear bag. smith work done by @Greg Taylor

Last edited:

none currently sir, I wanted to start competing this year at MCSA here in PA, which they have groundhog score matches (200,300,500) and 600 yard IBS style matches (no longer sanctioned by IBS). Maybe get involved at Williamsport down the road.@Benchrest Braxton

Which Benchrest disciple do you compete in Long range, short range , mid range ? IBS , NBRSA ? Freedom ?

This year is tough for me with all the OT at work (wife wanting lots of home improvements) and being a night shifter, but hope to come out swinging next year.

I do have a 300-500 yard backyard range that I shoot at when I get some spare minutes in the day in which I will conduct my testing.

Your measuring many variables related to brass only and ignoring everything else. Can you really test with an ordinary rifle, inexpensive bench rest, average shooting skills, poor wind reading skills, and average qualty bullets. Some guys test in a temperature controlled tunnel with a $6000 rifle with a $3500 scope and a $1200 front rest. Good luck. I decided my rifle with my skills will average around .350" sometime bigger which keeps me happy.why do we anneal? we anneal because we want to restore the brass to its state of original hardness from the factory.

why do we do want this? extend brass life, consistent springback (shoulder bump/neck tension) everytime, and consistent bullet seating forces. we want the brass to act the same before and after firing, everytime.

I think most people believe that keeping these factors consistent is conducive towards precision, therefore expect to achieve this through annealing.

How will annealing potentially show a difference on target? through keeping these factors (in which we can measure) consistently everytime. The flame isn't doing something else magical to the brass (that we cant measure) that makes it somehow change the way it makes a difference on the target.

This is why obtaining these measurements is the best way IMO to test annealing vs not annealing.

Your measuring many variables related to brass only and ignoring everything else. Can you really test with an ordinary rifle, inexpensive bench rest, average shooting skills, poor wind reading skills, and average qualty bullets. Some guys test in a temperature controlled tunnel with a $6000 rifle with a $3500 scope and a $1200 front rest. Good luck. I decided my rifle with my skills will average around .350" sometime bigger which keeps me happy.

i think a borden brmxd in a cerus stock with a brux barrel ($6k rifle) with a nightforce scope ($2,400), berger bullets, $2,200 front rest, etc etc is a pretty good rifle for some decent data.

i wont comment about my wind reading skills, but my young eyes are still good and i am capable of shooting in the 1's.

i'm not doing this to be some sort of definitive test, just want to collect some data, might put other things into perspective, who knows

Last edited:

DLT

Silver $$ Contributor

Let us knowI have split my share of Lapua 6br, Alpha 6 Dasher, and LC+Starline in 223. Seems like after 4-6 loads those necks do not like to get spread. None were annealed (but shot great). I just started annealing so i will see if the trend stops.

Dolomite

Silver $$ Contributor

Keep us updated, any test results would be interesting.i think a borden brmxd in a cerus stock with a brux barrel ($6k rifle) with a nightforce scope, berger bullets, $2,200 front rest, etc etc is a pretty good rifle for some decent data.

i wont comment about my wind reading skills, but my young eyes are still good and i am capable of shooting in the 1's.

i'm not doing this to be some sort of definitive test, just want to collect some data, might put other things into perspective, who knows

I noticed when the cases exited the flame on the Bench Source it looked like one side of the case was orange and the other side was black. He could have adjusted the flames better. Looks like he is trying to put the flame point (the hottest part of the flame) on the case. I don't like this alignment since it's a tiny hot location. I push the case into the flame so it wraps around the neck. The necks get orange in about 8 seconds with this method with a single handheld torch. I put the cases in a case holder from a neck turner and spin them in a small electric drill. The necks are uniform all the way around in orange color. I don't care what the hardness numbers or seating pressure is. It's good enough for my needs.This video was done by Eric Cortina

I’m looking forward to seeing what results you get @Benchrest Braxton

For me, I anneal after every firing. I have definitely noticed a difference with every new step I incorporated into my reloading practices over the years. I will say, the end result is a combination of all the steps involved. When I reload, I keep a checklist of all my steps so I don’t skip a step (work and married life don’t usually allow for a complete session, start to finish. Plus I reload standing up the entire session)

Here's my reloading process for anyone curious

This is the process that works for me, some may say it’s too much, I used to be one of those but I never attacked those that did.

All these steps give me a round that is as consistent as the last one and the next. The way I look at it is, the more variables I can eliminate the easier it is to diagnose things when performance changes.

I recently experienced this with my 22 Creedmoor, the accuracy went from a consistent .25 MOA to just over .5 MOA. Now that’s no big deal considering the rifle is still performing great, but I know what I was able to consistently print on paper and that wasn’t it. Because I know everything is the same everytime, I cleaned the rifle thoroughly, stripped the bolt, remade a dummy round to where the lands eroded to and made 4 sets of 3 rounds .015“ off the lands where I knew this rifle shot .25 MOA. I also added .20 grs of powder to compensate for the added case capacity from seating further out. Sure enough, the rifle went back to performing as it did before.

Here’s the target for those that are curious… FYI: I Use a Harris bipod and Armageddon Schmedium Rear Bag and some patience..

Again, my point here is I document everything I can or what I currently am able to with the tools that I have and it makes the hobby more enjoyable for me and not so much of a chore. I don’t use an apron like @Benchrest Braxton does, but do use the same surgical gloves like he does because, there’s no sense in getting chemicals and junk on my hands if I don’t have to. I love my wife and enjoy being with her as well as shooting, so cleanliness and preserving good health is important to me for her..

I hope this helps someone here and that’s the point of sharing. This forum has been good to me for a long time now and I feel it’s my responsibility to give back to it, that’s what keeps this community alive. Also, making friends is always gold and I’ve made my fair share on here too.

For me, I anneal after every firing. I have definitely noticed a difference with every new step I incorporated into my reloading practices over the years. I will say, the end result is a combination of all the steps involved. When I reload, I keep a checklist of all my steps so I don’t skip a step (work and married life don’t usually allow for a complete session, start to finish. Plus I reload standing up the entire session)

Here's my reloading process for anyone curious

- AMP Anneal Cases

- De-Prime

- Measure Headspace & Neck OD

- FL Resize to -.002” with neck Bushing

- Scrub Primer Pockets with RCBS Brass Boss

- Ultrasonic Wash (30 Mins)

- Wet Tumble Polish (30 Mins)

- Dry Brass

- Inspect Primer Pockets with Go/No-Go Gauge

- Prime Brass to -.008” with Derraco PCPS

- Mandrel Expand Case Necks

- Trim/Debur/Chamfer with Henderson Trimmer

- Dry Lube Inside Case Necks (Graphite/Mica Mix)

- Charge case with powder using RCBS Matchmaster

- Seat Bullet

- Measure loaded round CBTO

- Measure Loaded Round Concentricity

This is the process that works for me, some may say it’s too much, I used to be one of those but I never attacked those that did.

All these steps give me a round that is as consistent as the last one and the next. The way I look at it is, the more variables I can eliminate the easier it is to diagnose things when performance changes.

I recently experienced this with my 22 Creedmoor, the accuracy went from a consistent .25 MOA to just over .5 MOA. Now that’s no big deal considering the rifle is still performing great, but I know what I was able to consistently print on paper and that wasn’t it. Because I know everything is the same everytime, I cleaned the rifle thoroughly, stripped the bolt, remade a dummy round to where the lands eroded to and made 4 sets of 3 rounds .015“ off the lands where I knew this rifle shot .25 MOA. I also added .20 grs of powder to compensate for the added case capacity from seating further out. Sure enough, the rifle went back to performing as it did before.

Here’s the target for those that are curious… FYI: I Use a Harris bipod and Armageddon Schmedium Rear Bag and some patience..

Again, my point here is I document everything I can or what I currently am able to with the tools that I have and it makes the hobby more enjoyable for me and not so much of a chore. I don’t use an apron like @Benchrest Braxton does, but do use the same surgical gloves like he does because, there’s no sense in getting chemicals and junk on my hands if I don’t have to. I love my wife and enjoy being with her as well as shooting, so cleanliness and preserving good health is important to me for her..

I hope this helps someone here and that’s the point of sharing. This forum has been good to me for a long time now and I feel it’s my responsibility to give back to it, that’s what keeps this community alive. Also, making friends is always gold and I’ve made my fair share on here too.

Last edited:

Like you, I also use a reloading check list that I also make notes on for each time I reload. I only stand up during brass prep.I’m looking forward to seeing what results you get @Benchrest Braxton

For me, I anneal after every firing. I have definitely noticed a difference with every new step I incorporated into my reloading practices over the years. I will say, the end result is a combination of all the steps involved. When I reload, I keep a checklist of all my steps so I don’t skip a step (work and married life don’t usually allow for a complete session, start to finish. Plus I reload standing up the entire session)

Here's my reloading process for anyone curious

And don’t forget the best step of all.. SHOOT!!! LoL

- AMP Anneal Cases

- De-Prime

- Measure Headspace & Neck OD

- FL Resize to -.002” with neck Bushing

- Scrub Primer Pockets with RCBS Brass Boss

- Ultrasonic Wash (30 Mins)

- Wet Tumble Polish (30 Mins)

- Dry Brass

- Inspect Primer Pockets with Go/No-Go Gauge

- Prime Brass to -.008” with Derraco PCPS

- Mandrel Expand Case Necks

- Trim/Debur/Chamfer with Henderson Trimmer

- Dry Lube Inside Case Necks (Graphite/Mica Mix)

- Charge case with powder

- Seat Bullet

- Measure loaded round CBTO

- Measure Loaded Round Concentricity

This is the process that works for me, some may say it’s too much, I used to be one of those but I never attacked those that did.

All these steps give me a round that is as consistent as the last one and the next. The way I look at it is, the more variables I can eliminate the easier it is to diagnose things when performance changes.

I recently experienced this with my 22 Creedmoor, the accuracy went from a consistent .25 MOA to just over .5 MOA. Now that’s no big deal considering the rifle is still performing great, but I know what I was able to consistently print on paper and that wasn’t it. Because I know everything is the same everytime, I cleaned the rifle thoroughly, stripped the bolt, remade a dummy round to where the lands eroded to and made 4 sets of 3 rounds .015“ off the lands where I knew this rifle shot .25 MOA. I also added .20 grs of powder to compensate for the added case capacity from seating further out. Sure enough, the rifle went back to performing as it did before.

Here’s the target for those that are curious… FYI: I Use a Harris bipod and Armageddon Schmedium Rear Bag and some patience.. View attachment 1558538

Again, my point here is I document everything I can or what I currently am able to with the tools that I have and it makes the hobby more enjoyable for me and not so much of a chore. I don’t use an apron like @Benchrest Braxton does, but do use the same surgical gloves like he does because, there’s no sense in getting chemicals and junk on my hands if I don’t have to. I love my wife and enjoy being with her as well as shooting, so cleanliness and preserving good health is important to me for her..

I hope this helps someone here and that’s the point of sharing. This forum has been good to me for a long time now and I feel it’s my responsibility to give back to it, that’s what keeps this community alive. Also, making friends is always gold and I’ve made my fair share on here too.

- De-Prime

- Clean primer pockets with pocket uniformer

- Flame Anneal

- Clean Neck Shoulder with steel wool (~1/2 hr. per 100)

- FL size with non-bushing die, no expander ball (Imperial Sizing Die Wax)

- Dry tumble with rice (medium grain size), ~1hr

- Remove rice/media by handful and inspecting primer pockets and flash holes for remaining media

- Run expander mandrel through neck

- Check neck tension

- 3-way trim to length

- Prime cases to touch, seating depth depending on primer pocket depth and primer used (Lee ACP)

- Inspect primer seating depth sample for proper seating

- Charge cases with powder (powder weighed with FX-120i)

- Seat bullets (Harrell arbor press with Wilson seating die)

- Check for desired seating depth

This target should give you an idea of the kind of results I get with just a Ruger Precision Rifle 6.5 PRC with a 26" Preferred Barrel Blanks barrel that's got over 1,900 rounds on it now:

Nice Work. I also turn necks, I was just sharing my process after firing.Like you, I also use a reloading check list that I also make notes on for each time I reload. I only stand up during brass prep.Though the following are the steps in my reloading process, fire forming then turning the necks after the second firing is the only other thing I do, only once. After that, this:

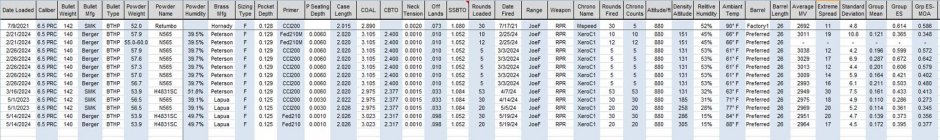

I record loading details and result details for all my outings:

- De-Prime

- Clean primer pockets with pocket uniformer

- Flame Anneal

- Clean Neck Shoulder with steel wool (~1/2 hr. per 100)

- FL size with non-bushing die, no expander ball (Imperial Sizing Die Wax)

- Dry tumble with rice (medium grain size), ~1hr

- Remove rice/media by handful and inspecting primer pockets and flash holes for remaining media

- Run expander mandrel through neck

- Check neck tension

- 3-way trim to length

- Prime cases to touch, seating depth depending on primer pocket depth and primer used (Lee ACP)

- Inspect primer seating depth sample for proper seating

- Charge cases with powder (powder weighed with FX-120i)

- Seat bullets (Harrell arbor press with Wilson seating die)

- Check for desired seating depth

View attachment 1558548

This target should give you an idea of the kind of results I get with just a Ruger Precision Rifle 6.5 PRC with a 26" Preferred Barrel Blanks barrel that's got over 1,900 rounds on it now:

View attachment 1558549

I was pleasantly surprised when I tried an elimination diet on my reloading process. I started pulling steps out, one at a time and shooting for several hundred rounds to see if things got worse or stayed the same. Occasionally I add a step back in again if I get worried about it but I have found that I don’t see any benefit to a great many things people swear by. Sometimes I swear people are attributing what was an increase in their shooting skill from shooting more often to some arbitrary step they added to their reloading process that they are “testing thoroughly”.

I have tried all the tricks, and when I started eliminating everything that didn't make a difference on target, I found a lot more time to shoot, as well as a much more enjoyable reloading process. Couldn't agree more.I was pleasantly surprised when I tried an elimination diet on my reloading process. I started pulling steps out, one at a time and shooting for several hundred rounds to see if things got worse or stayed the same. Occasionally I add a step back in again if I get worried about it but I have found that I don’t see any benefit to a great many things people swear by. Sometimes I swear people are attributing what was an increase in their shooting skill from shooting more often to some arbitrary step they added to their reloading process that they are “testing thoroughly”.

Similar threads

- Replies

- 43

- Views

- 2,193

- Replies

- 3

- Views

- 427

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.