So decided to give annealing a try

Now just to be clear why I didnt to begin with. KAK has stated ,that they made this up to be a simple deal for guys wanting to get into a .17cal centerfire. In their videos they stated all you need to do to convert brass is a single run into the resizing die. I wanted to test those claims. If I just went and ran buckwild on some more advanced ( yes annealing is kinda advanced for some) stuff then what would just kinda nullify that . It's like if I company said their after market engine will fit perfectly in a car but before you even tired to test fit you start cutting out the engine bay to make room or something. If that makes sense . Now according to them you want once fired brass because it's work hardened for initial forming. They said they initially tried annealing their brass but it resulted in too many crushed necks due to the soft annealed brass collapsing. And I can post a link to the video where they explain this if anyone wants.

Ok anyhow the test. Not the most scientific, took 20rd of brass from the same bag I've been working with. It's all been de capped cleaned ect . All same head stamp 23 Lake city 5.56. Made sure to chey they all had good looking case mouth and the like.

As far as the annealing just some Podunk flame change annealing with a 3/8's deep socket on a drill and a propane and torch. Angle isn't the best but trying to hit just that neck shoulder junction like your supposed to. Would have used my 750 tempilaq but I couldn't open the jar at all, and flame change always seems to work decent.

So our if the 20 , ten where annealed ten where not .

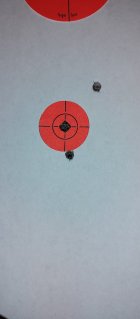

Interesting enough all the annealed ones seemed to have this same mark/pattern on them

So the it's the same as it's always been since I stared this . No de capping die, shoulder getting bumped back to 1.450". Hand lubing each one individually with imperial sizing wax

So our if the ten in annealed ones I got one crush

And the annealed ..... Well

All ten annealed ones where crushed , not one properly converted case....so yeahhhh, look like KAK was right with this one lol. Will be ordering a .20 cal due soon though as a step die.just gotta see what will work best , looking at possibly a .204 Ruger die or a .20 practical. Well see