Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6BR Pressure Found Low Charge

- Thread starter MikeG08

- Start date

Deleted member fkimble@charter.net

268 loaded round neck dia. is going into a .269 - .271 neck

So your neck is at least .271 and maybe a hair bigger. That gives you at least .003 clearance. You should be fine on clearance. We need to see a couple pics of the head end of those cases that were hard to open. Need to see them with the fired primer still in them. A good close-up with good focus.

Frank

So your neck is at least .271 and maybe a hair bigger. That gives you at least .003 clearance. You should be fine on clearance. We need to see a couple pics of the head end of those cases that were hard to open. Need to see them with the fired primer still in them. A good close-up with good focus.

Frank

dgeesaman

Gold $$ Contributor

Regarding the dented necks, just use your fingertip to keep the front of the case from pushing out until the bolt is entirely open. Then that fired brass will suitable to check for the bullet slipping cleanly out.

I'd call the smith who chambered this barrel and find out what the reamer neck diameter is. I have a .271 neck and that's as small as I'd ever consider a 'no-turn' neck because some brass is too thick for that. .272-.273 is far more common.

I'd call the smith who chambered this barrel and find out what the reamer neck diameter is. I have a .271 neck and that's as small as I'd ever consider a 'no-turn' neck because some brass is too thick for that. .272-.273 is far more common.

Larry Koch

Silver $$ Contributor

MikeG08

Silver $$ Contributor

That’s a beautiful thing. Yeah I’ve got nothing like that..268 nk 68 grain bt. Old brass still showing sine wave.

MikeG08

Silver $$ Contributor

I do run a bore scope every cleaning. I also clean my suppressor after each outing or if less than 50 rds every other. Excessive but I like to keep it clean. I keep the entire barrel bare metal after each outing.You might want to bore scope the muzzle end of the barrel, I run a suppressor on my 6 dasher and get a carbon build up from the muzzle in about 6 inches.

MikeG08

Silver $$ Contributor

The smith was Alpha and Omega tool in MO. They closed up shop. And unfortunately he is not reachable. Caleb Morris was the one who chambered.Regarding the dented necks, just use your fingertip to keep the front of the case from pushing out until the bolt is entirely open. Then that fired brass will suitable to check for the bullet slipping cleanly out.

I'd call the smith who chambered this barrel and find out what the reamer neck diameter is. I have a .271 neck and that's as small as I'd ever consider a 'no-turn' neck because some brass is too thick for that. .272-.273 is far more common.

spike-55

Gold $$ Contributor

Brass trim is 1.550 with Giraud Trimmer, Bullet is .040" back of JamFor measuring tools I only have a tube micrometer and a few pairs of Mitutoyo calipers.

All of the case mouths have a dented side, I’m assuming from extraction?

The bullet will fit in the fired case, but there is definite resistance.

The fired mouth is measuring .269” on the low side, then the other 3/4 of the case mouth measure .270-.271”

Loaded unfired round measures .268” all the way around.

So does that mean I’m only working with .001-.003” neck clearance?

Trimming to 1.550” OAL

you could be on the ragged edge of too long brass OAL. spec is 155.98 and depending on how the chamber is cut you could be a tad too long??? for as often as you clean there is no downside to being a couple thou short on brass OAL to prevent the brass from jamming into the end of the chamber. your cleaning routine will not allow a carbon ring to form if there were an increased chance. you might try on a few rounds and see if it will make a difference . - not sure what those dents in the case mouth are???? are they in the same location on the case each time???? can you pull one carefully by hand without letting it hit anything to see if the ejector is causing???

stan

MikeG08

Silver $$ Contributor

That was something I was getting at in my OP. I don't care about speed in this barrel. If I can get in a window at the lower charge and shoot I'm fine with that.You could fix it all by just going with the 28.0 gr load, it is your smallest group too...

I suppose as long as I'm not getting pressure signs it should be fine?

MikeG08

Silver $$ Contributor

I sized the brass already. My plan was to keep it separate and use that brass for foulers. I could load a couple at that lower charge where pressure starts if it would be beneficial.268 loaded round neck dia. is going into a .269 - .271 neck

So your neck is at least .271 and maybe a hair bigger. That gives you at least .003 clearance. You should be fine on clearance. We need to see a couple pics of the head end of those cases that were hard to open. Need to see them with the fired primer still in them. A good close-up with good focus.

Frank

MikeG08

Silver $$ Contributor

Another member posted on the dent, I will use my finger to keep the case pushed in so it doesn't dent right as its coming out.Brass trim is 1.550 with Giraud Trimmer, Bullet is .040" back of Jam

you could be on the ragged edge of too long brass OAL. spec is 155.98 and depending on how the chamber is cut you could be a tad too long??? for as often as you clean there is no downside to being a couple thou short on brass OAL to prevent the brass from jamming into the end of the chamber. your cleaning routine will not allow a carbon ring to form if there were an increased chance. you might try on a few rounds and see if it will make a difference . - not sure what those dents in the case mouth are???? are they in the same location on the case each time???? can you pull one carefully by hand without letting it hit anything to see if the ejector is causing???

stan

What would a good trim length be 1.545"?

spike-55

Gold $$ Contributor

yes i think you would be fine with 1.540 or 1.545. there will be no issue with accuracy and with you cleaning regimen a carbon ring will never form and that would be the only downside of slightly short brass. i too am surprised at your seating depth??? most BR cases like to be in the .010 in the lands to .010 jump. you usually find a load within .005 either direction that will remain pretty stable.Another member posted on the dent, I will use my finger to keep the case pushed in so it doesn't dent right as its coming out.

What would a good trim length be 1.545"?

stan

ps- i like about .004 into the lands

Last edited:

MikeG08

Silver $$ Contributor

So when I say jam I’m using Erik Cortina’s method for finding the stuck bullet jam point.yes i think you would be fine with 1.540 or 1.545. there will be no issue with accuracy and with you cleaning regimen a carbon ring will never form and that would be the only downside of slightly short brass. i too am surprised at your seating depth??? most BR cases like to be in the .010 in the lands to .010 jump. you usually find a load within .005 either direction that will remain pretty stable.

stan

ps- i like about .004 into the lands

Prep case as normal, seat very long, apply imperial wax to the ojive and chamber the round so that the barrel is seating the bullet further down the neck. I repeated this twice and took the longer of the 2. They were within .002” of each other.

I believe this method likely goes deeper in than just touching?

I have the Hornady tool but not a BR case to measure.

MikeG08

Silver $$ Contributor

So I loaded up some more rounds this evening and plan to shoot them Sunday. Looks like a lighter wind day.

Loaded up 3rds @27.60 and 3 @27.80. I will shoot these on the same target style as the previous powder ladder.

I loaded 8 foulers @ 28.0.

I also loaded 16@ 28.0 to shoot some more groups to see if the previous groups repeat.

I trimmed all of the cases to 1.545” OAL.

Loaded up 3rds @27.60 and 3 @27.80. I will shoot these on the same target style as the previous powder ladder.

I loaded 8 foulers @ 28.0.

I also loaded 16@ 28.0 to shoot some more groups to see if the previous groups repeat.

I trimmed all of the cases to 1.545” OAL.

what is your chamber length ?? most of mine are 1.570 and most new Lapua brass is 1.555 out of the box and rarely need trimmed--I suspect a donut in those cases that were high pressure--see if a bullet will drop thru the neck --if you have resized them them seat a bullet and measure the neck dia. right at the shoulder junction and see if they are near .271-.272--I think the donut is causing your problem--Roger

MikeG08

Silver $$ Contributor

Ended up getting out back today. Probably should have waited until tomorrow. The wind was stronger than when I tested last time.

This photo was virgin brass trimmed to 1.545”

28.0gr. The impact to the far right and the left both had heavy bolt lift. The one on the right was very heavy. I took some pictures of the brass as I was out there since the light was so good.

3 of the 5 shots had heavy lift with the one on the right being very heavy. Here are the pieces of brass that were heavy fresh out of the chamber.

I noticed 2 levels of rings around the necks. Are they too short now?

Lol..

This photo was virgin brass trimmed to 1.545”

28.0gr. The impact to the far right and the left both had heavy bolt lift. The one on the right was very heavy. I took some pictures of the brass as I was out there since the light was so good.

3 of the 5 shots had heavy lift with the one on the right being very heavy. Here are the pieces of brass that were heavy fresh out of the chamber.

I noticed 2 levels of rings around the necks. Are they too short now?

Lol..

Attachments

Last edited:

MikeG08

Silver $$ Contributor

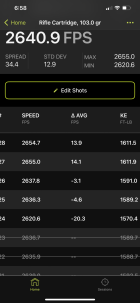

Here’s the chrono data on the last 5 shots.Ended up getting out back today. Probably should have waited until tomorrow. The wind was stronger than when I tested last time.

This photo was virgin brass trimmed to 1.545”

28.0gr. The impact to the far right and the left both had heavy bolt lift. The one on the right was very heavy. I took some pictures of the brass as I was out there since the light was so good.

3 of the 5 shots had heavy lift with the one on the right being very heavy. Here are the pieces of brass that were heavy fresh out of the chamber.

I noticed 2 levels of rings around the necks. Are they too short now?

View attachment 1494391

Lol..

That's a sweet group Larry and I won'tr disagree but I'm not sure how much value the sine wave on necks really has. If I post a group or several that are the same or even smaller, but with cases that don't show the sine much at all, does that mean anything? I can but my point is not that but I used to look for that pattern a lot and I can't say that I can conclude much from it on target. So, I'm not sure what it's telling us..268 nk 68 grain bt. Old brass still showing sine wave.

I don't get it nearly as much with 6 Grendel Lapua brass as I'm use to seeing with most others. I suspect it has something to do with the neck being a tad shorter than ppc or br necks but I'm not sure. All I know is two things. I've had tight neck and no turn versions of 6 Grendels and I can't see the sine on either and the target tells me there is no difference on paper. Not saying it doesn't have some value. Again, I lived by the same rule for a long time. This is strictly experience doing it both ways and not seeing it matter on the target. I've always heard that the sine will correspond with the lugs too...a 2 lug has two dips, a 3 lug has three dips and they line up with the lugs. I can't confirm that either as I've never found it to be consistently true.

I'd like to know what it's telling me for sure but whatever it is is small and I can't say that I can shoot the difference either way. The guns/bbls have good records so it's not like they are non-competitive either way. To the contrary, they've been very competitive both ways. So, I don't know.

Last edited:

Similar threads

- Replies

- 11

- Views

- 3,591

- Replies

- 23

- Views

- 2,092

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.