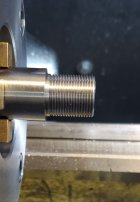

It's a rod that you can put a pilot bushing on.

One end in the barrel, other end in your tailstock chuck. Hang a small weight from the rod, and now you can indicate on the rod to dial your barrel.

They're especially handy for finding the right size pilot you'll need.

Thinking about it, probably the worst way to hold a barrel--in terms of potential over-tightening--is with a 4-Jaw with small aluminum shims at the end of the jaws....the shims we use to allow the barrel to articulate. Those small contact points with the clumsy way we have to tighten a 4-Jaw would seem to easily allow over tightening.

Then again, I have shot several screamer groups at 1000 yds with barrels I have chambered using a 4-Jaw with small shims, so maybe none of this is a big deal......

The four jaw chuck with short aluminum shims works well if you are careful with the tightening. The aluminum shims grip the barrel well. This is probably the preferred setup for those doing only a few chambers.

I've been using this front spider for 8 years now on my Jet 1024 because I am too lazy to make a threaded backplate for a set thru chuck.

Once I thought I am dialed in, I loosen a screw to check deflection, re-dial if need be. I try to achieve equal torque between opposing screws where I can loosen a screw and see very minimal needle movement.

Seems to work well in this lightweight 90s vintage even threading straight in with the cross slide.

I like that style of set up... but I want to figure out a way to make those 4 blocks fixed to the bolts... similar to a typical F style clamp

I like that style of set up... but I want to figure out a way to make those 4 blocks fixed to the bolts... similar to a typical F style clamp

View attachment 1426010

Do like they did on that clamp and peen the entry around the back half of the ball.

Do like they did on that clamp and peen the entry around the back half of the ball.

Could make a die of sorts and use a hydraulic press to move enough material to capture the end of the screw if you wanted to get really fancy.

Could make a die of sorts and use a hydraulic press to move enough material to capture the end of the screw if you wanted to get really fancy.

He has bearing balls epoxied into the tips. Figure out a way to weld those on there then move the material and it would be nice. Theres no pressure coming back out so it wouldnt take much just enough to keep em from falling off

I like that style of set up... but I want to figure out a way to make those 4 blocks fixed to the bolts... similar to a typical F style clamp

View attachment 1426010

Modify the feet

He has bearing balls epoxied into the tips. Figure out a way to weld those on there then move the material and it would be nice. Theres no pressure coming back out so it wouldnt take much just enough to keep em from falling off

I was thinking.. cut a groove in the bolt... then in each of the "barrel blocks" I could put a pin/set screw that falls into that groove.

Would be hard to fit that into a 2 inch opening

Simple way to check if your setup is trying to flex the barrel is to loosen up the outboard spider and pull the barrel off center. Then tighten up you inboard spider. Does the muzzle end move? If it does then your setup will flex a barrel. Or another way would be to dial in a barrel, then loosen the outboard spider. The barrel should still be dialed in.

Would be hard to fit that into a 2 inch opening

I've used these before, pocket in the pads, epoxy tip into it

Shame they dont have those in fine thread.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

www.mcmaster.com

I could make those work...

This is a great idea , and to make the blocks "floating " and captured you could radius machine the jack bolt and block then machine a clearence counterbored loose fit capture screw from the bottom ?

I like it... but I'm not sure I can drill and tap a ball bearing very well

I still think this is a slick idea.

I still think this is a slick idea.

View attachment 1426072

That is the best way if you could come up with an edm machine

I still think this is a slick idea.

View attachment 1426072

That will fight you. The contact point changes if the barrel is not straight. It will want to self center.

That is the best way if you could come up with an edm machine

Many lathe chucks use a modular jaw system where you can bolt "soft jaw" blanks to the hardened scrolling backers and machine the blanks as required. Heres the concept