Does bullet lube spin off after leaving muzzle? If not could it affect flight of a bullet? I see my paper patch is shredded off about 4-10 feet after muzzle

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does bullet lube spin off after leaving muzzle?

- Thread starter Free Trapper

- Start date

Yes, 97% of it.

Well, in my experiences of "mining" lead from various impact areas since about 1965 (until maybe 2000 when I gave up searching) it appears to me that in most cases it stays in the groves.

Now, with that as background I have found a number of spent rounds that showed evidence of having some sort of lube. If it spun off in flight or was ground off by impact, I have no clue.

Also, I should mention that the lubes I remember were of different colors and I guess that means different quality/manufacturer/ and other variables that would effect the lubes ability to stay put.

Now, with that as background I have found a number of spent rounds that showed evidence of having some sort of lube. If it spun off in flight or was ground off by impact, I have no clue.

Also, I should mention that the lubes I remember were of different colors and I guess that means different quality/manufacturer/ and other variables that would effect the lubes ability to stay put.

I did try first but with no result so I posted lol. I've never been worth a dam at using search. I'll try harder now that I know their information to be found, thanks. Free TrapperIt depends on the lube. Softer ones are generally more likely to spin off and harder ones less likely. You can do a search and read about this and theories on how it may affect accuracy on various cast bullet forums.

A good Alox based grease will stay with a .45 with it's slower

velocity's and spin. My hot .357's with the same grease throws

it right off. And note, .45 ACP bullseye shooters with real low

velocity's have no problem with accuracy. A friend of mine tried

a moly powder back in the day, and we tested on my Ransom

rest. It was all the rage, but really never panned out with little

to no gain.

velocity's and spin. My hot .357's with the same grease throws

it right off. And note, .45 ACP bullseye shooters with real low

velocity's have no problem with accuracy. A friend of mine tried

a moly powder back in the day, and we tested on my Ransom

rest. It was all the rage, but really never panned out with little

to no gain.

Last edited:

SSL

Gold $$ Contributor

It should stay on the bullet as long as it is in the barrel. The old rule of thumb was to look at the muzzle after several shots and see if there was a star-shaped smear of lube corresponding to the groves of the firearm on the crown. The idea being that if did not appear, the lube was being burned/rubbed off inside the bore and was not doing its job all the way down the barrel. If the lube is too hard, it isn't likely that it is doing its job in the bore and should be evident from not seeing that 'star' too.Does bullet lube spin off after leaving muzzle? If not could it affect flight of a bullet? I see my paper patch is shredded off about 4-10 feet after muzzle

As to affecting the bullet flight...if the lands and grooves are gripping properly (correctly sized bullets) and the lube is being equally distributed on the bullet so shouldn't cause accuracy problems by itself.

Just my reasoning and what I've experienced.

sean68

Silver $$ Contributor

Just Google “cast bullet lube spin off” and you can read all night about it. I used to shoot in cast bullet benchrest competitions and it can have an affect on accuracy. If the lube partially spins off or is hard and some chunks come off one side it can create an imbalance. Many guys used very soft lubes and wanted it to instantly and completely spin off as soon as the bullet leaves the muzzle.

If we are talking about pistols or open sighted leverguns you might not need to think about it, but with my 30br Panda and 42x Nightforce trying to win a match, it matters.

If we are talking about pistols or open sighted leverguns you might not need to think about it, but with my 30br Panda and 42x Nightforce trying to win a match, it matters.

JSH

Gold $$ Contributor

SSL is spot on.

A lot of lubes are not much more than melted crayons. If it stays on during bulk shipment it is good lube.

I have cast and shot a pound or two of cast bullets in rifle and pistol. I make my own lube as I only found a couple that really worked. Never had a leading issue that was a lube problem, size is King.

I have seen store bought bullets that hit steel a d the lube was still on them in spots.

A lot of lubes are not much more than melted crayons. If it stays on during bulk shipment it is good lube.

I have cast and shot a pound or two of cast bullets in rifle and pistol. I make my own lube as I only found a couple that really worked. Never had a leading issue that was a lube problem, size is King.

I have seen store bought bullets that hit steel a d the lube was still on them in spots.

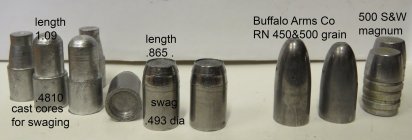

Thanks sean68, building muzzleloader rifle for the grandkid to hunt with. He just turn 14 an like's those big bullets so setting him up with a GM .50-.510 1:28 barrel with a peep sight, OK the peep sight was for me lol. So looking for a good bullet to shoot, knowing him and with iron sites still be thinking of that 200-400 yard shot. I try loading 500 S&W Mag FN 440g bullets .8 inch something long. So far no luck with it at 50 yard 20 inch spread some little side ways. Got to be doing something wrong no bullet can suck that bad. Using Lee mold and sizing die .501 bullets do load easy. Having better luck with Buffalo Arms 450g RN lead bullet 1.126 inch long for paper patching. Today shot a group of five 3-4 inch at 50 yards before the rain push me back in doors. OK I will Google until my old eyes blur up, thanks for the info. Free TrapperJust Google “cast bullet lube spin off” and you can read all night about it. I used to shoot in cast bullet benchrest competitions and it can have an affect on accuracy. If the lube partially spins off or is hard and some chunks come off one side it can create an imbalance. Many guys used very soft lubes and wanted it to instantly and completely spin off as soon as the bullet leaves the muzzle.

If we are talking about pistols or open sighted leverguns you might not need to think about it, but with my 30br Panda and 42x Nightforce trying to win a match, it matters.

Thinking must of pick up lots of cast groove bullets and can't remember if they still had lube lol, bet I'll remember next time.I mine quite a few of my 45 ACP's. My range backstop is often the end of a log. When that log rots, the bullets are laying there. The wax is always still in the grooves.

I used LEE LIQUID ALOX lube on those 500 S&W Mag FN cast bullets. Hoping some body can show me what I'm doing wrong, Bullets do load easy but very poor group at 50 yards and some looking like they were starting to go side ways, thanks. Free TrapperSSL is spot on.

A lot of lubes are not much more than melted crayons. If it stays on during bulk shipment it is good lube.

I have cast and shot a pound or two of cast bullets in rifle and pistol. I make my own lube as I only found a couple that really worked. Never had a leading issue that was a lube problem, size is King.

I have seen store bought bullets that hit steel a d the lube was still on them in spots.

JSH

Gold $$ Contributor

There are some tutorials and findings on casting for revolvers around. Chamber, cylinder throat, forcing cone and then the bore diameter.

What OD is your bullet?

In a nut shell look for “choke” or at least the same all the way to the muzzle.

If you start of say at.505, then it drops to .500 some where in the middle, but your barrel groove is .503, all the love and care won’t help.

I cull my CB’s really hard. They need to look exactly like the inside of the mold.

I quit using molds made for the masses, to much margin of error, like the box of chocolates ya. Ever know what your gonna get.

Some slugging and measuring will tell you in short order where your problem is and what is needed to fix it. Then buy a custom mold. They are a bargain for what you get.

If one just wants to shove a bullet in a case with good results stick with jacketed to relieve frustration.

What OD is your bullet?

In a nut shell look for “choke” or at least the same all the way to the muzzle.

If you start of say at.505, then it drops to .500 some where in the middle, but your barrel groove is .503, all the love and care won’t help.

I cull my CB’s really hard. They need to look exactly like the inside of the mold.

I quit using molds made for the masses, to much margin of error, like the box of chocolates ya. Ever know what your gonna get.

Some slugging and measuring will tell you in short order where your problem is and what is needed to fix it. Then buy a custom mold. They are a bargain for what you get.

If one just wants to shove a bullet in a case with good results stick with jacketed to relieve frustration.

Marine says "crayons?"SSL is spot on.

A lot of lubes are not much more than melted crayons. If it stays on during bulk shipment it is good lube.

I have cast and shot a pound or two of cast bullets in rifle and pistol. I make my own lube as I only found a couple that really worked. Never had a leading issue that was a lube problem, size is King.

I have seen store bought bullets that hit steel a d the lube was still on them in spots.

Thanks JSH for your input, I have a GM .50 cal bore barrel groove to .510, 1:28 twist, Setup for muzzleloading. Cost was a big factor in trying 500 S&W MAG, FN 440 grain bullet. Lee mold for that bullet came with a .501 sizing die plus LEE LIQUID ALOX lube. Said bullet coated with ALOX loaded easily smooth down the barrel on top of 70g 2FF follow by card wad, felt lube wad and another card wad than seated bullet. Bullet has a solid base, been casting with pure lead no tin as of yet. Grouping was so bad I just stop playing with it and went to a paper patch bullet from Buffalo Arms Co trying 450-500g swag RN 1.0560 - 1.1415 long .492 dia, smooth sides no lube groove. At 50 yards shooting 3-4 inch groups with Iron sights (peep for us old guys) I like the Buffalo Arms paper patch bullet but are not cheap. I do plan on making my own swaging dies will post pictures on my first attempt in trying. Still would like to make that 500 S&W MAG bullet work, using Miller stability formula Calculate bullet at 3.485 on the green chart, numbers reading between 1.03-2.0 are suppose to be the best. My Paper patch bullets measure 2.062-2.211 on the green chart, seem longer bullets make them more stable.There are some tutorials and findings on casting for revolvers around. Chamber, cylinder throat, forcing cone and then the bore diameter.

What OD is your bullet?

In a nut shell look for “choke” or at least the same all the way to the muzzle.

If you start of say at.505, then it drops to .500 some where in the middle, but your barrel groove is .503, all the love and care won’t help.

I cull my CB’s really hard. They need to look exactly like the inside of the mold.

I quit using molds made for the masses, to much margin of error, like the box of chocolates ya. Ever know what your gonna get.

Some slugging and measuring will tell you in short order where your problem is and what is needed to fix it. Then buy a custom mold. They are a bargain for what you get.

If one just wants to shove a bullet in a case with good results stick with jacketed to relieve frustration.

I have a wood backstop of railroad ties at 615 yards. I used to occasionally find the same bullets I just shot, lying around, still hot, sometimes with a slight bend or dent, depending on what they hit.

My observation of recovered bullets is that those fine little uneven teeth in the meplat of Berger bullets look exactly as when loaded, the did not melt, close or open. (Tipping is not at all pointless). Plastic tipped bullets typically retained those tips, but I never saw one melted. Rifling was preserved perfectly to evidence bore alignment, symmetry and lack of bore defect, in the jackets, and they retained carbon residue detail sufficiently to even discern whether the barrel needed to be cleaned or not.

Marker ink certainly does not shoot off. I never noticed whether anything like solvent would remain in trace amounts. I don’t think trace fluid would affect their flight significantly. We somehow can shoot through or perhaps displace many raindrops at long range without seeing deflection.

My observation of recovered bullets is that those fine little uneven teeth in the meplat of Berger bullets look exactly as when loaded, the did not melt, close or open. (Tipping is not at all pointless). Plastic tipped bullets typically retained those tips, but I never saw one melted. Rifling was preserved perfectly to evidence bore alignment, symmetry and lack of bore defect, in the jackets, and they retained carbon residue detail sufficiently to even discern whether the barrel needed to be cleaned or not.

Marker ink certainly does not shoot off. I never noticed whether anything like solvent would remain in trace amounts. I don’t think trace fluid would affect their flight significantly. We somehow can shoot through or perhaps displace many raindrops at long range without seeing deflection.

Google 500 S&W Magnum handgun showing one model using 1:18.75 twists. Muzzle velocity 1625 F/s, cast bullet dia .501 Using Miller stability calculator shows that bullet stability 8.267 in green chart.Unless your barrel is totally leaded up I don’t think your issue is lube. I would look into twist rates and diameters if you have bullets going sideways.

With my GM barrel .50 cal-.510 groove 1:28 twist muzzle velocity 1150 F/s bullet dia .501 show bullet stability 3.485 in green chart.

I read stability value should be in the range of 1.3 to 2.0 to ensure bullet stability. I'm a little lost, so a bullet with 8.267 in green chart better or worse?

Last edited:

JSH

Gold $$ Contributor

I reread everything I think.

So your trying to use a bullet intended for 500SW in a 50 caliber muzzle loader?

The 500SW is a .501 bore where as the BP rig is .510. The muzzle loader is a 1-28 ROT where as the 500 SW is listed as a 1-18.75 ROT.

Undersized and too slow of a twist are working against you. The design does not lend itself well to a muzzle loader either I would think.

I may have some 50 caliber projectiles I would offer you if you want to try them, dead soft mini ball.

I tried some Lee target stuff years ago with no success.

I went back to a patched round ball in my Hawken. Sacrilegious I know, but I put a small red dot on it and it is the hammer of Thor to 100.

So your trying to use a bullet intended for 500SW in a 50 caliber muzzle loader?

The 500SW is a .501 bore where as the BP rig is .510. The muzzle loader is a 1-28 ROT where as the 500 SW is listed as a 1-18.75 ROT.

Undersized and too slow of a twist are working against you. The design does not lend itself well to a muzzle loader either I would think.

I may have some 50 caliber projectiles I would offer you if you want to try them, dead soft mini ball.

I tried some Lee target stuff years ago with no success.

I went back to a patched round ball in my Hawken. Sacrilegious I know, but I put a small red dot on it and it is the hammer of Thor to 100.

Similar threads

- Replies

- 17

- Views

- 707

- Replies

- 16

- Views

- 943

- Replies

- 5

- Views

- 1,134

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.