I do have a bore scope and I will do as you suggested.I would do a few things. Measure the diameter of the .200 line on another piece of brass that closes just fine and compare it to a piece that has just been fired, and then to a piece that has just been resized. Do you see a difference in that dimension?

Do you have access to a Teslong borescope? You can insert it from the chamber side to see if you have a carbon ring that has gradually built up, or anything else impeding the chamber. You can insert it from the crown end with a closed bolt (to include an empty case, not a live round) to see if your necks are too long.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harder bolt close after sizing

- Thread starter Chiquita

- Start date

Try measuring the body shoulder junctionI do have a bore scope and I will do as you suggested.

Annealed case fits fine. I noticed when I sized it then it was a hard bolt close. Again, I don't remember having this issue in the past.Pay particular attention to the neck and shoulder junction and the shoulder to body.

About the only way to increase diameter of the case while sizing would be to crush the shoulder, possibly from too soft after annealing. This would show up at the body to shoulder area.

If the sizing ball is pulling the neck forward on the way out, it would mark at the base of the neck. Sizing a problem case without the expander would prove this as the problem, if it fits after sizing.

The key is a fired case fits before you anneal and size.

What happens to a fired case that you do not anneal before you resize?.

dellet

Gold $$ Contributor

Sorry wasn’t clear with my question.Annealed case fits fine. I noticed when I sized it then it was a hard bolt close. Again, I don't remember having this issue in the past.

What happens if you size a case that has not been annealed?

Ccrider

Gold $$ Contributor

I have seen case get longer moving the shoulder forward during sizing. The black marker will tell you where contact is being made.

It is pretty simple. The case is either too long, too long at the shoulder or too big at the 200 line.

If everything is fine after firing with no bolt click, my bet is that it is the shoulder and you need to bump it back more.

It is pretty simple. The case is either too long, too long at the shoulder or too big at the 200 line.

If everything is fine after firing with no bolt click, my bet is that it is the shoulder and you need to bump it back more.

drop_point

Silver $$ Contributor

What type of die? Is it possible the die lock ring has had the threads stretched out with use? I agree with the black sharpie trick, I've used it myself a time or two.

Same, harder bolt close.Sorry wasn’t clear with my question.

What happens if you size a case that has not been annealed?

Redding full size die.What type of die? Is it possible the die lock ring has had the threads stretched out with use? I agree with the black sharpie trick, I've used it myself a time or two.

Big_Daddy

Gold $$ Contributor

THIS^^^^^Try measuring the body shoulder junction

If you have a bore scope, put in a case close the bolt. Scope from muzzel and see where case mouth is.

My 30br was too long. I even got a ring die thinking .200 line ...

If no bore scope trim case that is tough to close on and see if it gets better.

Distance between the edge of the brass and the end of the chamber with the bolt closed. I have plenty of room.

.004 and .005 "excessive" you mean the case shrank too much or not enough?So with the Redding you are sizing :

.0015 at the .200 line

.004 at the CSJ - (excessive )

.002 length -bump ( increase here)

Small base die:

.0015 at the .200

.005 at the CSJ- (excessive )

.002 length -bump

Just my 2 cents

Put away the Redding competition shell holders. Use a standard shell holder. Normal shell holder has a deck height of .125"with .004 shell holder

How does the competition shell holder screw things up and make the harder bolt close?Put away the Redding competition shell holders. Use a standard shell holder. Normal shell holder has a deck height of .125"

dellet

Gold $$ Contributor

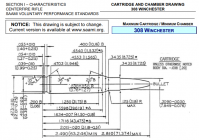

I don’t load 308, so I’m a bit confused with the numbers and the drawing.

How are you getting your measurement?

Are you using a different diameter tool than .400” to get your 1.57+ number?

Are you just measuring to the shoulder with calipers?

As I said I’m not familiar with the 308 cartridge but your numbers don’t make sense to me.

If you are not measuring to the actual datum, it would all make sense. The shoulder will move forward and lengthen, before the die contacts the shoulder and pushes it back. This would cause your problem and using the standard shell holder would likely correct it.

But we need that length number at the .400” diameter of the shoulder to know for sure.

Your “C” measurement is being referred to as “base to Datum” in your first post. This is base to shoulder. Base to datum would be measured as drawn, close to the center of the shoulder at a spot that is .400” diameter and should be somewhere around 1.630”. Note the drawing below.

How are you getting your measurement?

Are you using a different diameter tool than .400” to get your 1.57+ number?

Are you just measuring to the shoulder with calipers?

As I said I’m not familiar with the 308 cartridge but your numbers don’t make sense to me.

If you are not measuring to the actual datum, it would all make sense. The shoulder will move forward and lengthen, before the die contacts the shoulder and pushes it back. This would cause your problem and using the standard shell holder would likely correct it.

But we need that length number at the .400” diameter of the shoulder to know for sure.

Last edited:

47WillysGuy

Gold $$ Contributor

| His | Mine | Saami | |

| A | 0.453 | 0.453 | 0.455 |

| B | 0.470 | 0.470 | 0.470 |

| C | 1.5685 | 1.615 | 1.634 -0.007 |

I compared OP numbers to the SAAMi drawing and my .308 numbers and His "C" which is a headspace number is almost 0.065 of an inch different from Sami and 0.046 of an inch from my readings. I used the Hornady "D" insert to get the 1.615" my headspace dimension.

Saami's dimension from case head to body/shoulder junction is 1.5598, OP's dimension of His "C" is 1.5685 which gives a difference of almost 0.009 of an inch difference.

As dellet says, "But we need that length number at the .400” diameter of the shoulder to know for sure."

The 1.5685" dimension is suspect to me... What tools/method are you using to get the 1.5685" number?

JMayo

Silver $$ Contributor

Here is another couple of thoughts ...

Sholder angle of die not matching chamber.

Calipers not reading correctly.

Method in which measurements are being taken.

Lol you've got from A to Z being thrown at you. Good luck. Let us know when you find that needle in that haystack !

Sholder angle of die not matching chamber.

Calipers not reading correctly.

Method in which measurements are being taken.

Lol you've got from A to Z being thrown at you. Good luck. Let us know when you find that needle in that haystack !

Similar threads

- Replies

- 21

- Views

- 629

- Replies

- 18

- Views

- 2,639

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.