MikeMcCasland

Team Texas F-T/R

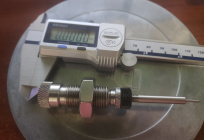

If a primer pocket was pushed towards the case head, is it possible to push it back out?

Current depth is .101, depth on a new pocket should be around .120. 6BRA brass.

Dillion super swage is an option, or uniform it, but I suspect there's not enough material to uniform it out.

Current depth is .101, depth on a new pocket should be around .120. 6BRA brass.

Dillion super swage is an option, or uniform it, but I suspect there's not enough material to uniform it out.