Well... Why wouldn't the throat be straight?

If you're indicating the throat, and an inch foward, the breech end becomes unknown. You pre-bore to solve the potential issue you're talking about. It's to get the body aligned perfect to what you've dialed in for the throat.

If you're letting the pilot take your reamer for a walk, you'll end up with oversized or oval chambers.

If your reamer would have been in a bind due to your concern, it would also be in a bind without the pre-bore.

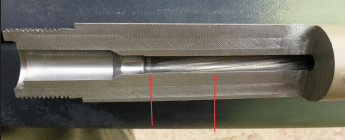

I started boring with a "TS-C06K-SCLCR06" tiny carbide bar. I use the polished inserts made for aluminum. They take light/finish cuts in stainless and leave a gorgeous finish.

View attachment 1370723

It's not that the throat isn't straight. It's the back end of the chamber that might not be. Yes I understand that when we prebore after drilling--assuming no deflection of the boring bar--the hole we bored is aligned with the spindle.

However, if we don't also dial in the back part of the chamber, then it's very possible that while the throat is straight that the back of the chamber is running out. In fact, the entire back of the chamber up to the throat is running out.

After preboring we have the prebored part running true, a potential area of some runout, and then a true throat. We are hoping that part running out won't influence the reamer. However, if the pilot happens engage the area before the throat that is running out, vs the actual throat, there is misalignment and potential issues.

My method is to dial from near the back of the chamber to a little in front of the throat. That way that 2-3" of bore is running true to the spindle. Then when I cut the chamber the pilot is is staying in the true part of the bore. The hole the reamer is making--using a floating reamer holder--is fully supported and also true to the bore. I think this is a better way of chambering--at least right now. I may change my mind later. If were to prebore I'd still dial in the same way, but based on how I dial in I see no advantage to preboring, but do see possible issues.

Again, don't get too wrapped up in this. We are talking theory here. In actual practice the differences are so minimal that it really doesn't matter. Crud, dialing in the breech and muzzle with range rods and then cutting the chamber has produced a lot of very accurate barrels....