You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Where should I look for the cause of the flyer?

- Thread starter diego-ted

- Start date

BoydAllen

Gold $$ Contributor

Another little Savage trick: The order that you tighten the action screws, and the way that you do it matters. After you just have the slack out of the screws, set the rifle on its butt, so that the weight of the barreled action is on the recoil lug, and start your tightening sequence with the front screw, and work to the back. Tighten them in stages, and always start with the front screw. Never tighten the back one first on a Savage. Another thing that can bite you is the front scope base screw. Its hole bottoms on the barrel, and because of that, if the screw is just slightly too long, you may think that it is properly clamping the base to the action, when it is bottomed in the hole. The way that I deal with all "blind" holes is to precisely note where the screw starts to engage, by turning it in a half turn or so, and then carefully backing it out until I hear the click that happens when the start of the thread falls as it passes the beginning of the female thread. I do this with the base off the action, counting the half turns till the screw bottoms, and note the number. It might be something like 4 1/4 turns to bottom. Then I mount the base and do the same thing. If the number is the same, the screw is not clamping the base to the receiver, and it needs to be shortened. I usually like to have a half turn of difference. I do this anywhere on the rifle where there is a hole that is not open on its bottom, and something is being clamped in position. In some case this applies to action screws as well. One classic that can happen with Savages is that after you finish tightening the front action screw, the bolt cannot be opened, or becomes difficult to operate, this because the hole in the receiver lines up with the front lug, and the stock has compressed to the point where the screw is bearing on the end of the lug.

BoydAllen

Gold $$ Contributor

I know that this does not comport with the common practice, but I have always tightened action screws by feel. I know that this does you no good at all, but it is the way that I do it. With factory, or skim glass bedding, I am feeling for how much pressure the stock material seems to be able to take, and with pillars, I am feeling for screw stretch. Over the years, I have rebuilt a number of car and truck motors, and for those applications, I have always used a torque wrench, but for other applications and some of the places on those motors that I did not have a torque spec for, I had to do some educated guessing, working by feel. I should ad that this feel came at the expense of a few mistakes, luckily not expensive ones.

[br]gstaylorg said:Hey Ted,

Why don't you bring it out to SBRGC Saturday with a few rounds of your best handload. I'll bring some AB175s and we can see how it performs with a few groups in both our hands after the match. If we're both getting fliers with both types of ammo...well, then you know. If one ammo or shooter does not get the fliers, maybe the rifle is fine as it is.

GT

Best suggestion, yet. Those loads are certainly accurate in Greg's GAP.

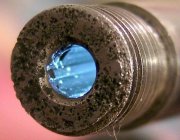

it seems to me that you have had good comments regarding your dilemma, I have a Sako 223 which has a Pez moderator fitted,however I left it on the rifle and placed it

muzzle down in the gun safe as advised to stop any condensation running down the tube,don't know if you guys are allowed moderators on your rifles,don't do what I did!! this is the result,you can see that the groupings are really bad note the flyers to the left of target shots taken at 100yds,your groupings are good apart from your

flyers,hope this puts some light on your problem,I had mine counter sunk and re crowned and is back to it's old self, have you Checked the crown on your rifle?. target has not properly presented its self top is where the clips are

muzzle down in the gun safe as advised to stop any condensation running down the tube,don't know if you guys are allowed moderators on your rifles,don't do what I did!! this is the result,you can see that the groupings are really bad note the flyers to the left of target shots taken at 100yds,your groupings are good apart from your

flyers,hope this puts some light on your problem,I had mine counter sunk and re crowned and is back to it's old self, have you Checked the crown on your rifle?. target has not properly presented its self top is where the clips are

Attachments

Greg, I truly appreciate the offer; however, the rifle is 2/3 of the way to New Hampshire by now. Steve’s suggestion along with those of others here, as well as my own research has dictated the rifle will be better served with a good pillar bedding. Larry from LPR Gunsmithing has a lot of experience with this particular platform. He has a service for the stock and trigger which includes tuning the action and lapping the lugs. He will bed action in the stock using bisonite and steel pillars. The service also includes trigger honing to a good sharp let-off. He is going to bore scope the barrel and give it a good looking over. He will diamond lap it, re-crown it and even do chamber work if needed.

I bought this rifle and was told there were only about 200 rounds down the tube? I have no way of knowing. I just think at this point instead of wasting money burning up hard to locate components for the nominal fee for the services above, I feel, I will be better off and dollars ahead, taking care of the variables and removing them from the equation. My only concern at this point is gambling on the factory barrel? Not sure if I should just bite the bullet and put a custom tube on it and be done for now?

I will wait until Larry has taken a look at the barrel and see what he finds.

As always thanks to everyone for their input and help.

Diego

I bought this rifle and was told there were only about 200 rounds down the tube? I have no way of knowing. I just think at this point instead of wasting money burning up hard to locate components for the nominal fee for the services above, I feel, I will be better off and dollars ahead, taking care of the variables and removing them from the equation. My only concern at this point is gambling on the factory barrel? Not sure if I should just bite the bullet and put a custom tube on it and be done for now?

I will wait until Larry has taken a look at the barrel and see what he finds.

As always thanks to everyone for their input and help.

Diego

mikegaiz

Stay frosty, my friend.

Something I have used when dealing with getting a proper screw lengths and blind action holes is to drop a single #9 piece of lead shot in the whole and then tighten it down. if it is smashed to smithereens the screw is too long. if it is just smashed 50% or so, it is about right. That is just my approach. it may help.

Tim Singleton

Gold $$ Contributor

I've read through this post a couple times. I see you have tried different loads with same results.

What are the components you are using. My 308 savage ftr acted in a similar way until I switched to Berger's. it didn't shoot well at all with the Amax or even the sierra's

What are the components you are using. My 308 savage ftr acted in a similar way until I switched to Berger's. it didn't shoot well at all with the Amax or even the sierra's

I would say 80 percent of my development was with the Hornady 178 HPBT, I ran about 40 rounds of Berger 185 juggernauts and about 40 rounds of the Honady Amax. They all produced about the same results? When the rifle comes back I am just going to work on a load for the 185 Junggers!

Diego

Diego

Similar threads

- Replies

- 16

- Views

- 3,294

- Replies

- 5

- Views

- 1,367

- Replies

- 7

- Views

- 1,417

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.