urbanrifleman

Site $$ Sponsor

All I know, is after reading all this back and forth, rigamoro, said this ,said that, Is Im buying another barrel from the urban rifleman. It might be considered a prefitt by some but after I get it, and run my own loads through it, it's CUSTOM!

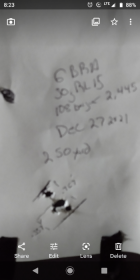

ThaTreece texted me this target just now.

View attachment 1302733

That is 250 yards.

That is a factory chamber... $249 nut barrel that I sell.

Yes sir. I shot that one today.Treece texted me this target just now.

View attachment 1302733

That is 250 yards.

That is a factory chamber... $249 nut barrel that I sell.

I was going to post that. PS: What is a failed machinists?So the companies who are knowledgeable and skilled enough to manufacture a barrel are not as competent to then chamber and thread it?

Bradley, I had to laugh. Who hasn't danced in their underwear?

Impossible! Now I’m all triggered…where’s my Xanax and emotional support cat?Somehow several of us managed to shoot fclass records with them, not bad for casual shooters.

Little is truly custom in our game. Actions certainly aren’t custom, they are named models that are precisely machined in a “factory” with minimal handwork to hopefully be exactly the same, one to another. If they weren’t the same, then you couldn’t order up a chambered barrel, which all the smiths can and do fill, based on specs. It would be pointless and frustrating to have more than one of them. Items that are produced exactly alike are the opposite of “custom.”

A stack of barrels made to a “spec” before a customer has ordered them isn’t in any way problematic to me, if the barrels are good. We rely on specs all the time on parts with tighter tolerances and greater costs. Most “f-open” barrels don’t even have a contour, we call them custom anyhow but they are cut bar stock, plain cylinders, that have no front or rear. They are drilled and rifled, usually tracing a giant screw’s twist, with nothing attached, indexed, tapped, planed, threaded, or coated onto them; definitely not custom to a particular gun, with the only non-automated decision having been made, being when to stop lapping them.

My powder, brass, primers and bullets better not be custom. I don’t think getting right a shouldered pre-threaded barrel’s head-spacing is necessarily harder than other tolerances the action is not provided for. A trigger’s 100% reliable sear engagement with cocking pieces is the most important function of a gun but I haven’t had any difficulty interchanging unmodified pre-made bolts, triggers, hangers, etc. Many bolt upgrades and different faces from inventory across brands manage perfect integration as well.

Very pretty!

Just cut this one.

Looks good, lands are nice and square.

Just cut this one.

I am not a gunsmith. But I have looked at many chambers like your video shows. But the 6BR Savage video looks like you have a land that runs all the way back to the neck on one side. So chamber would be off .0003-.0005 depending on free bore diameter size. The finish on the chamber looks different than what I have seen. Are you polishing or sanding the chambers and free bore?