Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

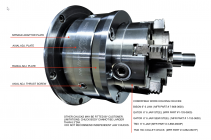

True Bore Alignment System

- Thread starter urbanrifleman

- Start date

BuffaloBill

Silver $$ Contributor

Sure, that makes sense. I’ll try to eliminate pieces if I can. I went ahead and ordered one of those cheap 160mm chucks. Will find out when it shows up mid (?) August.You can always make an intermediate backing plate.

xr650rRider

Silver $$ Contributor

ER-50 Collets with .0002" runout or less are going to be pricey.

BuffaloBill

Silver $$ Contributor

Runout in the collet would be dialed out, correct?

xr650rRider

Silver $$ Contributor

Runout in the collet would be dialed out, correct?

If your attaching to TBAS and nothing moves, I assume you can.

BuffaloBill

Silver $$ Contributor

You know, I’ve made a beautiful one-piece spider/D1-6 with ball pivoting pads. And it works just fine. Nice and short, keeping the work as close as possible to the headstock bearing. Very rigid, etc. The thin-ish pivoting pads being an attempt to help minimize bending the barrel when adjusting the outboard spider. I try to further minimize stresses by loosening the front adjustment screws and retightening them, after having set the outboard spider to where I think it will remain. I probably spend 1-1.5 hrs doing this. And that’s ok since I’m retired and this is just a hobby.

But I like the concept of chucking the barrel at the chamber end, to by design, not stress it by manipulating its other end. So I will try the TBAS. I do plan on using the outboard spider, as others already mentioned, adjusting it to contact the barrel after the dialing-in is finished.

I do wonder though, how much more challenging it will be to dial-in, not being able to position the throat area at a pivot point. Alex commented on this a number of pages back and I agreed with him. Being able to use one measurement point at the pivot, eliminates interaction between the two spider adjustments, etc.

So maybe it will take me even longer to dial in. I’ll possibly have gained only the experience, and a lighter wallet……..

I’ve never worked with ER50 collets. I read that the stated size is the maximum they will accept and that they will compress to 2mm less than the nominal diameter. With that in mind, for working with 1 1/4” shank barrels, I ordered a 32mm collet. Was that the right move?

But I like the concept of chucking the barrel at the chamber end, to by design, not stress it by manipulating its other end. So I will try the TBAS. I do plan on using the outboard spider, as others already mentioned, adjusting it to contact the barrel after the dialing-in is finished.

I do wonder though, how much more challenging it will be to dial-in, not being able to position the throat area at a pivot point. Alex commented on this a number of pages back and I agreed with him. Being able to use one measurement point at the pivot, eliminates interaction between the two spider adjustments, etc.

So maybe it will take me even longer to dial in. I’ll possibly have gained only the experience, and a lighter wallet……..

I’ve never worked with ER50 collets. I read that the stated size is the maximum they will accept and that they will compress to 2mm less than the nominal diameter. With that in mind, for working with 1 1/4” shank barrels, I ordered a 32mm collet. Was that the right move?

Attachments

DaveTooley

Gold $$ Contributor

The TBAS is for axial alignment. Radial adjustments are independent of that system. I'm not sure how a fixed collet system attached to a TBAS will work. I believe they make an adjustable 16C collet holder but the price is astronomical.If your attaching to TBAS and nothing moves, I assume you can.

jareese

Gold $$ Contributor

Dave am I misunderstanding your statement about the Radial being "independent of that system"? I can do both Axial and Radial adjustments on my TBAS...The TBAS is for axial alignment. Radial adjustments are independent of that system. I'm not sure how a fixed collet system attached to a TBAS will work. I believe they make an adjustable 16C collet holder but the price is astronomical.

DaveTooley

Gold $$ Contributor

I have never had hands on one so I might be mistaken. Do you adjust radially with the TBAS or the adjustable chuck? If it's with the chuck and you replace it with a fixed collet chuck then what?Dave am I misunderstanding your statement about the Radial being "independent of that system"? I can do both Axial and Radial adjustments on my TBAS...

DaveTooley

Gold $$ Contributor

It sucks.I do wonder though, how much more challenging it will be to dial-in, not being able to position the throat area at a pivot point. Alex commented on this a number of pages back and I agreed with him. Being able to use one measurement point at the pivot, eliminates interaction between the two spider adjustments, etc.

The inside dial point moves roughly 30% of your outside point on an anglier adjustment.

Example. You're roughing in and the throat is running true, but you have .003 at the breech. You need to "overshoot" and make a .004 anglier adjustment measured at the breech because the throat is going to move also. Now you need to make a .001 "radial?" adjustment in the opposite direction. It gets to be a lot of tail chasing just to get close.

Also, I spent a several years doing laser alignments on rotating equipment and his "radial" and "axial" terminology is ass backwards to me.

Last edited:

BuffaloBill

Silver $$ Contributor

Thanks, I envisioned it working kind of like you explained. I designed electronic circuits prior to retirement. In the days before microcontrollers, we used potentiometers in analog circuits. Most of the time there’d be gain and offset pots. On circuits where the two cal pots interacted, people would over time, get pretty good at tweaking them in. I imagine it will take some time to get a feel for this.It sucks.

The inside dial point moves roughly 30% of your outside point on an anglier adjustment.

Example. You're roughing in and the throat is running true, but you have .003 at the breech. You need to "overshoot" and make a .004 anglier adjustment measured at the breech because the throat is going to move also. Now you need to make a .001 radial adjustment in the opposite direction. It gets to be a lot of tail chasing just to get close.

Also, I spent a several years doing laser alignments on rotating equipment and his "radial" and "axial" terminology is ass backwards to me.

I got around it by not rotating the chuck and traversing between my two points and making angular adjustments until I got the same readings, then repeating for the other set of screws before I began my "radial" adjustments.Thanks, I envisioned it working kind of like you explained. I designed electronic circuits prior to retirement. In the days before microcontrollers, we used potentiometers in analog circuits. Most of the time there’d be gain and offset pots. On circuits where the two cal pots interacted, people would over time, get pretty good at tweaking them in. I imagine it will take some time to get a feel for this.

I think that's the idea behind using his rods since it eliminates traveling over the lands.

WSnyder

Silver $$ Contributor

Same technique is key for dialing in actions for truing.I got around it by not rotating the chuck and traversing between my two points and making angular adjustments until I got the same readings, then repeating for the other set of screws before I began my "radial" adjustments.

I think that's the idea behind using his rods since it eliminates traveling over the lands.

Alex Wheeler

Site $$ Sponsor

Dialing the z axis like that will align the bore with the ways, ok if the ways are dead nuts in line with the spindle rotation centerline. I would still always check two points radially. I have seen where guys dial the z and just check the radial in one spot.I got around it by not rotating the chuck and traversing between my two points and making angular adjustments until I got the same readings, then repeating for the other set of screws before I began my "radial" adjustments.

I think that's the idea behind using his rods since it eliminates traveling over the lands.

Right. That's why I used the plural of "adjustments" but I wasn't very clear I guess.I would still always check two points radially.

The instructions for the TBAS tell you to radially check both ends as a final step also, even when using the rods.

I was only trying to describe a quick way to rough it in. The "coupling" effect isn't nearly as dramatic when you're tweaking out the last few tenths.

Similar threads

- Replies

- 2

- Views

- 873

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.