There easy to find the lands on a brand new unfired barrel also.With any barrel job, I always ask for a "gizzy". IMO they are the best tool for several jobs, not just measuring bump.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Too much bump?

- Thread starter Texas Solo

- Start date

Takes a little more time but as fired has a little extra bolt lift.

(Savage 22N) so I size feeling for a tiny bit of bump with a body only die and fit check a few in the actual chamber.

For a match all sized are fit check.

(Savage 22N) so I size feeling for a tiny bit of bump with a body only die and fit check a few in the actual chamber.

For a match all sized are fit check.

kd4avp

Gold $$ Contributor

Got my first "gizzy" on a recent 22BR build. My smithy used a cut off portion of the barrel to make it. VERY handy tool to have on hand. Sure makes setting the die up easier. Getting very consistent sizing numbers using this method. Keep it in the same box as the Wilson bullet seater so I always know where it is.Lots of folks have what many call a "bbl gizzy", made from the bbl cutoff, with the same reamer that cut the chamber. The reamer is just run in deep enough to form most of the shoulder. It can then be used like a comparator but is specific to your chamber. IMO, it doesn't get much better than that. It can also be used to verify neck clearance and seating depth. Simple and easy to use tool that is quite handy and accurate. As you can imagine, it does away with datum issues etc. Lots of smiths used to provide them to customers, often as part of the chamber job.

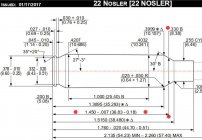

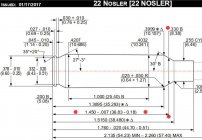

For 22 Nosler I took an extra 30 cal comparator bushing and reamed it

until I got an acceptable reading (1.448" ) with the Go Gage (1.450").

I get the same with a 7.62x39 steel case belled.

Aluminum Black for Identification.

I shoot a 22N ar-15 with a little more bump than the wife's 22N Savage.

Set the Savage headspace to TIGHT (by about 0.001-0.002") with the Go-Gage. Nosler 22N brass and factory ammo is SHORT.

I can size for both with the same setting.

until I got an acceptable reading (1.448" ) with the Go Gage (1.450").

I get the same with a 7.62x39 steel case belled.

Aluminum Black for Identification.

I shoot a 22N ar-15 with a little more bump than the wife's 22N Savage.

Set the Savage headspace to TIGHT (by about 0.001-0.002") with the Go-Gage. Nosler 22N brass and factory ammo is SHORT.

I can size for both with the same setting.

Last edited:

JMayo

Silver $$ Contributor

I try to cover all the ranges of my brass. Yep some are bumped half a thou + too much.Not to high jack the thread, but tangentially related... I've been measuring my fired Lapua brass for my 260 Rem I've been working with and they seem to vary by 2 or 3 thou. If one were to bump 2 thou during resizing, do you set the die to bump 2 though based on the longest fired case or shortest fired case?

FWIW I set it based on the shortest case this last time. It's also a hunting rig so I might be splitting hairs for the intended purpose but enjoy trying to make it shoot the smallest groups possible.

6MMsteve

Gold $$ Contributor

don't never try to gain by head spacing long.... you will have serious issues...always try to headspace as the gauge allows... it will be lots better and brass will last much longer...I would re headspace and start overTo clarify:

I gave it .002 headspace when I installed the barrel.

Shoulder measurement is post firing vs sized.

Texas solo you had this question before. You should figure out how to measure shoulder bump. The way .007 will cause brass head separation in a short number

How much bump is safe?

My bolt closure is tight, even with factory Fed GMM 168. I sized and trimmed new Hornady brass and set the seating depth at -.005" off the lands. It's also tight. Next I bumped the shoulder .002" and it's only slightly better, so I think I found the issue. Question is how much bump is...forum.accurateshooter.com

That issue was with 308, not 6 Dasher

Alex's method is the way I do bump and find touch, I have used a gizzy to I have some for some of my guns.Barrel off touch point is pretty simple way of documenting the case or bullet stick point or touch point.

Speedy has a video if anyone is interested .

memilanuk

Gold $$ Contributor

What is a “gizzy”?

It's where a gunsmith takes the cut-off stub from a barrel blank, runs the chamber reamer into it, and sends it back to the customer with the gun/barrel. It should (in theory) give an exact replica of the actual chamber to test case sizing and/or bullet seating on... at least up until the point that the throat starts to move in the real barrel.

memilanuk

Gold $$ Contributor

That was always my take on them as well. But that'll get you roasted by the BR folksInteresting but after some rounds pretty useless too. First I heard of that in over 30 years in precision rifles.

I'm becoming more of a fan of the L.E. Wilson case gauge micrometer... I've kind of toyed with the idea of finding someone to make me a full-on case gauge from my chamber reamer, so it'd be an 'exact' fit. Not entirely sure that I'd actually gain anything from it over using the stock case gauge for common calibers. I guess if someone has an extra special super secret custom-dimensioned chamber reamer maybe they'd see a benefit... maybe.

Not if they like you.I assume this is an additional charge by the guy chambering the barrel ?

I really guess it depends if they even consider doing it for their customers. The last smith I used didn’t do it.

Mike Bryant in Texas has done 2 for me in the past.How many times have you had one made free ?

I have every time it has been a few years, I actually have made my own couple times.How many times have you had one made free ?

divingin

Gold $$ Contributor

How many times have you had one made free ?

My smith has made one on 3 of the 4 barrels I've had mounted and chambered. No extra charge as far as I know (his pricing seems to be kind of fluid anyway.)

Dimner

I do believe in Captain Crunch.

One other thing I'll add. Bump 0.002 or use the stripped bolt drop (Wheeler) method and follow those directions. Shoot what ever is more accurate. However all things being equal, 0.002 off fire formed brass seems to save me a whole heck of alot more brass trimming. I hate trimming....

Rope2horns

Norm Harrold

To me .002 shoulder bump is someones one size fits all....I like a clean stripped bolt drop +.001-.002 for fclass/hunting. YMMV

Last edited:

Similar threads

- Replies

- 47

- Views

- 19,985

- Replies

- 25

- Views

- 1,462

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.