You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tension Testing - It is official!!! According to Instron there is such a thing as tension testing

- Thread starter ireload2

- Start date

Using military data as a direct guide for what produces the very best accuracy attainable is an obvious mistake, since the military does not produce any ammunition that would be competitive at the highest level of competition. Certainly it is perfectly valid for the purpose that it was developed. This is a perfect example of trying to substitute data that was not developed for the same situation. We have a very good tool for evaluating what produces the best accuracy, it is called a target. The average shooter has no practical way to gauge release force of his ammo. About the best that can be done is to monitor seating force which may be related but is not the same thing. Uniformity has generally proven to be better than lack of, but experiments have shown that less release force (admittedly not measured directly) does not always give the best accuracy. For every application there seems to be an optimal value, that may not be the most or least obtainable. Targets are used to make this determination. Being more specific 133 likes more release force than T32.those specs only tell what the military established.

Measuring their bullets' release force enables them to reveal another variable in their ammo that changes muzzle velocity. They should learn that less with a smaller spread enables lower ES and SD numbers

Another thing that has been referred to in this thread is the application of statistical methods to accuracy. Certainly if large resources are available this is a valid approach, but the typical shooter is faced with a much different problem, an expensive barrel that has a relatively short accuracy life, perhaps one rifle, imperfect test conditions that are not able to be controlled, and so on. What I would like to read is how someone proposes to use advanced statistical methods to efficiently work up a competitively accurate load in the fewest number of shots. Perhaps there is something there to be learned, perhaps not.

In order to come up with the best solution for a problem, one first has to fully understand the problem, in many cases I have observed that people who have great skills and a high level of education may not fully understand a problem before attempting to solve it. They literally do not know what they do not know. This is sort of like having a shop full of tools, but not being able to diagnose why a car is not running properly.

Another thing, I really would hope that at some point one of these statistics experts would speak to the point of people referring to SDs of very small samples.

If you knew much about statistics you would know that it takes a sample of between 25 and 30 to provide statically valid results.

When you try to generalize about intelligent people solving problems you are just as guilty of not knowing what you do not know.

When you try to generalize about intelligent people solving problems you are just as guilty of not knowing what you do not know.

Using military data as a direct guide for what produces the very best accuracy attainable is an obvious mistake, since the military does not produce any ammunition that would be competitive at the highest level of competition. Certainly it is perfectly valid for the purpose that it was developed. This is a perfect example of trying to substitute data that was not developed for the same situation. We have a very good tool for evaluating what produces the best accuracy, it is called a target. The average shooter has no practical way to gauge release force of his ammo. About the best that can be done is to monitor seating force which may be related but is not the same thing. Uniformity has generally proven to be better than lack of, but experiments have shown that less release force (admittedly not measured directly) does not always give the best accuracy. For every application there seems to be an optimal value, that may not be the most or least obtainable. Targets are used to make this determination. Being more specific 133 likes more release force than T32.

Another thing that has been referred to in this thread is the application of statistical methods to accuracy. Certainly if large resources are available this is a valid approach, but the typical shooter is faced with a much different problem, an expensive barrel that has a relatively short accuracy life, perhaps one rifle, imperfect test conditions that are not able to be controlled, and so on. What I would like to read is how someone proposes to use advanced statistical methods to efficiently work up a competitively accurate load in the fewest number of shots. Perhaps there is something there to be learned, perhaps not.

In order to come up with the best solution for a problem, one first has to fully understand the problem, in many cases I have observed that people who have great skills and a high level of education may not fully understand a problem before attempting to solve it. They literally do not know what they do not know. This is sort of like having a shop full of tools, but not being able to diagnose why a car is not running properly.

Another thing, I really would hope that at some point one of these statistics experts would speak to the point of people referring to SDs of very small samples.

Last edited:

You are making a very erroneous assumption.

You could probably pull test a sample of military ammo and find a correlation between the value of the bullet pull, accuracy and accuracy.

Just because you want to look down your nose at military ammo does not mean that it is not affected by bullet pull variations.

You could probably pull test a sample of military ammo and find a correlation between the value of the bullet pull, accuracy and accuracy.

Just because you want to look down your nose at military ammo does not mean that it is not affected by bullet pull variations.

Using military data as a direct guide for what produces the very best accuracy attainable is an obvious mistake, since the military does not produce any ammunition that would be competitive at the highest level of competition.

How come military members win matches with their military handloads and rifles they rebuilt setting records in competition with civilians and their stuff in local, national and international events? Lt. Gary Anderson used military produced ammo from the Army's AMU to win gold in Olympic 300 meter free rifle matches with hollow point bullets they had Sierra make for them.since the military does not produce any ammunition that would be competitive at the highest level of competition.

All you "stiff receiver" afficianados need to know in the 50's, the US Army AMU had Winchester make 20 Model 70 receivers without a magazine cutout; heavy and solid bottom single shot ones for long range match rifles. They shot their handloads as good as any rifle today.

Some shot their way onto the US Palma Team with military rebuilt bolt rifles (and some shooting 7.62 Garands) with their shops hand loaded ammo.

Last edited:

He didn't use tensions, he uses holds. MattYou won't have to, fguffey will do it for you! dedogs

Less doesn't always mean smaller numbers. Smaller numbers doesn't mean smaller groups at 1000. Mattthose specs only tell what the military established.

Measuring their bullets' release force enables them to reveal another variable in their ammo that changes muzzle velocity. They should learn that less with a smaller spread enables lower ES and SD numbers

Poor engineering, think Titanic. Many poor cases of engineering over the years. I have taught 1000 yard benchrest school for over 8 years. Do you know who always did the worst? The engineers and rocket scientists. They wouldn't listen because They knew better. The guy that never loaded or shot far did the best, becuase he listened and learned. MattI bet you don't know what you are talking about because you have never been an engineer and you have never brought a product on line. Anyone that has been an engineer would not make such a general statement. Furthermore you apparently don't understand that marketing and management dictate many of the constraints that limit manpower, budget, research and testing of a new design. You are blaming engineers for the cost cutting goals that come from management's desire to make a bigger performance bonus.

For example many automotive engines do well to last 150,000 miles when a diesel truck engine can easily last much longer. The ability to make a very long lasting engines had been around for more than 50 years. It is not the fault of the engineers if management wants to sell engines with a limited oil sump capacity just to cut down on the number of quarts of oil that roll out the door in the crankcase.

On top of that you apparently cannot tell the difference between design issues and manufacturing defects. Often they appear to be one and the same. Without conducting failure analysis you may not know. I have seem many surgical instruments fail due to incorrect materials and heat treat. I have also seen many that failed because the surgeons beat them to death.

Sometimes stupid customers don't take care of and maintain their car properly. One of my high school acquaintances blew up his 375 Hp 396 Chevelle engine drag racing it - twice. He got 2 new short blocks installed under warranty. Do you really think poor engineering caused that?

CharlieNC

Gold $$ Contributor

In the fiber business I have worked with these for 45 years. The predecessors of the new electronic vacuum tube models were ingenious mechanical contraptions. It would be straightforward to make a set of clamps to hold the base and bullet, whereby the instrument would then pull the bullet out at a prescribed rate while constantly measure the pullout force. Similarly the instrument operation is reversible such that neck compression behavior could be tested. While contract lab rates are reasonable it is beyond what individuals are willing to pay. On the other hand it is a bit surprising that major bullet manfacturers have not invested in these types of studies to incorporate into their reloading manuals, as such investments would surely reap sales rewards. Astute loading technicians would develop the means to implement the results on the bench, without such instruments.

Regarding the statistical aspects noted above I have invested many hours writing about the aforemented topics, with little resulting interest.

Regarding the statistical aspects noted above I have invested many hours writing about the aforemented topics, with little resulting interest.

Alex Wheeler

Site $$ Sponsor

+1 And women too, no ego to get in the way. If more women were interested in the shooting sports they would dominate IMO.Poor engineering, think Titanic. Many poor cases of engineering over the years. I have taught 1000 yard benchrest school for over 8 years. Do you know who always did the worst? The engineers and rocket scientists. They wouldn't listen because They knew better. The guy that never loaded or shot far did the best, becuase he listened and learned. Matt

Which should be protested! They have a natural bipod" Artificial support" they do not have a pulse issue throwing them out of the black because they have no HEART!+1 And women too, no ego to get in the way. If more women were interested in the shooting sports they would dominate IMO.

dmoran

Donovan Moran

If you knew much about statistics you would know that it takes a sample of between 25 and 30 to provide statically valid results.

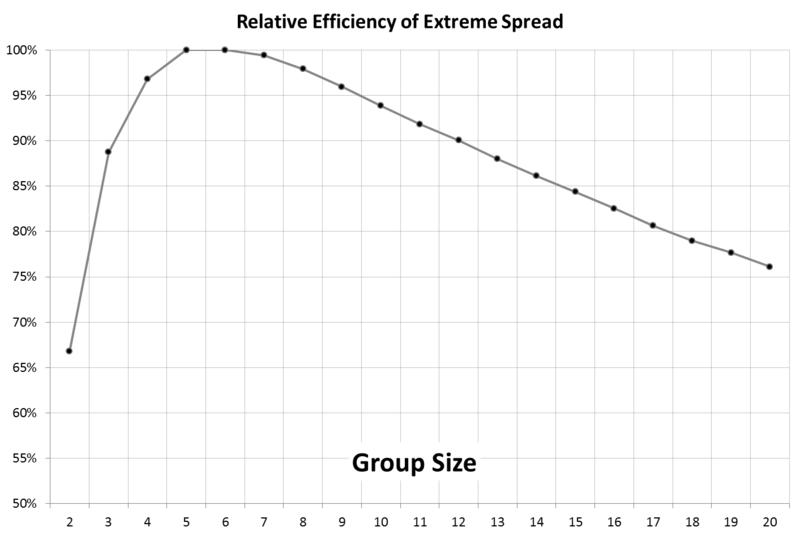

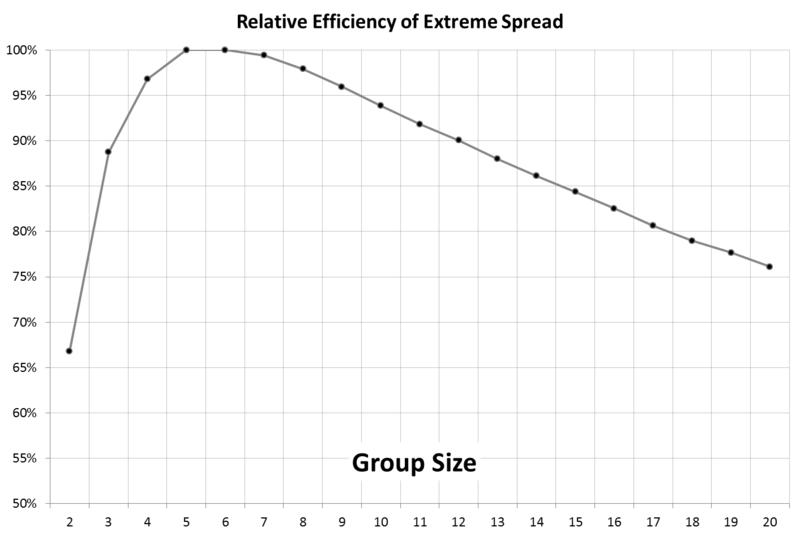

Here is the best range statistic to apply to the majority of reloaders/shooters:

The relative efficiency of sample size needed for load testing and development will quash most statistic analyzers.

Below is an example of an efficient amount of shots (5) fired per increment, which in this case was for locating an optimal seating depth for a long range load:

By your own input between 100 and 120 rounds would need to be fired instead, which would be grossly inefficient.

Last edited:

I think it peaks at 3 or 4 shots. 5 or 6 are too many for some folks.Here is the best statistic that applies to the majority of reloaders/shooters:

The relative efficiency of sample size needed for load testing and development will quash most statistic analyzers.

Mulligan

Silver $$ Contributor

If you knew much about statistics you would know that it takes a sample of between 25 and 30 to provide statically valid results.

When you try to generalize about intelligent people solving problems you are just as guilty of not knowing what you do not know.

Wouldn't that depend on the population size?

If a barrel is good for 1200 competitive rounds, are you really suggesting one would need a sample size of ~2 1/5% of the population to be valid?

Tony B. scraps a barrel at near 700 rounds. if we need 25-30 rounds to answer each question, a barrel will only have one match left it after all the testing.

I think with a smaller population, a smaller sample will get you to the confidence level you are seeking. Knowing a watchful eye is needed to separate the signal from the noise.

CW

If one shoots 3, 5, 7 or 10 shots per test group, there's a 95% probability that all groups will be somewhere in the following percentage spread of what one group's extreme spread is:

3 shots, 41% to 244% If it's 1 inch, 95% of all the others will range from .41" to 2.44".

5 shots, 66% to 153%

7 shots, 74% to 134%

And you don't know if that single, few-shot group fired is at the large end of several or the small one. Ten or twenty shot groups are better:

10 shots, 81% to 116%

20 shots, 89% to 112%

Mean radius is popular; here's an example of a 270-shot 600-yard test target with a mean radius of 1.9 inches from group center:

Extreme spread is about 10 inches. Rings at 6 and 12 inches; 1 and 2 MOA.

Some of those 3- an 5-shot clusters are under an inch.

3 shots, 41% to 244% If it's 1 inch, 95% of all the others will range from .41" to 2.44".

5 shots, 66% to 153%

7 shots, 74% to 134%

And you don't know if that single, few-shot group fired is at the large end of several or the small one. Ten or twenty shot groups are better:

10 shots, 81% to 116%

20 shots, 89% to 112%

Mean radius is popular; here's an example of a 270-shot 600-yard test target with a mean radius of 1.9 inches from group center:

Extreme spread is about 10 inches. Rings at 6 and 12 inches; 1 and 2 MOA.

Some of those 3- an 5-shot clusters are under an inch.

Last edited:

dmoran

Donovan Moran

.... Ten or twenty shot groups are better:....

By my own experience, I strongly disagree, and feel that would be grossly inefficient. Especially since your saying 40 to 80-rounds would need to be fired verses 20 to 24, to a same scenario (seating increment testing). Plus there is the expense factors to both reloading costs and barrel life, and the time frame and ambient control factors to testing/development.

Brians356

Silver $$ Contributor

To the optimist, the glass is half full. To the pessimist, the glass is half empty. To the engineer, the glass is twice as big as it needsEngineers can be indispensable....but they tend to think that because they have a "hammer" that every thing is a nail, or that because their calculations are complicated that they have visualized the problem correctly. All in all, the guys that are the best that I have seen at solving on the ground, get the job done sorts of problems have not been engineers. On the other hand when you need one, nothing else will do.

to be.

-

If we get back to the basics and look to dor example SAAMI when it comes to tension they do define "Neck Tension" as:

My earliest experiences with tension and measuring tension involved using and checking for accuracy tensionmeters as used to measure the tension of aircraft cables which controlled control surfaces. Tension being a unit of force as measured in pounds of force. Tension itself comes in a wide range of flavors most of which have little to do with the neck tension of a cartridge case and this being a shooting forum I figure it is best to focus on what we commonly call neck tension or bullet hold. As long as we understand what it is and share the same channel I doubt it matters what we choose to call it. While SAAMI provides the above definition they make no mention of how to measure it or the units of measure.

Using a load cell we can measure both compression (force required to seat a bullet) and tension (force required to pull the seated bullet) as expressed in PSI (Pounds Square Inch) or for our metric friends Pascals.

Now does anyone have a clue the force required to break away and pull for example a .308 Winchester round or .223 Remington? With the same neck thickness would all .308 or .224 diameter bullets be the same? I have no idea?

What I do figure is this. As the tension becomes more and more uniform the group sizes should get smaller. Like anything else with a hand or for that matter factory loaded round the more uniform and consistent everything is the more uniform and smaller the resultant groups.

As to all the chatter involving engineers or engineering? To measure neck tension or bullet seating depth and do it accurately you will need a Mechanical type and for the data acquisition you will need an Electrical type. That or a hell of a good tool and die maker and a hell of a good electronics technician.

Ron

That being about as good as it gets. They do not call out a unit of measure and for what it may or may not be worth they do not define "Bullet Hold". They do define "Bullet Puller" as:NECK TENSION

The circumferential stress that the case neck exerts on the seated bullet, as a result of the interference fit provided by the case neck inside diameter and the bullet outside diameter.

The first definition while not calling out a unit of measure does mention "an instrument" at least.BULLET PULLER

1. An instrument that measures the force required to extract a bullet from live ammunition.

2. A tool used to remove bullets from live ammunition.

My earliest experiences with tension and measuring tension involved using and checking for accuracy tensionmeters as used to measure the tension of aircraft cables which controlled control surfaces. Tension being a unit of force as measured in pounds of force. Tension itself comes in a wide range of flavors most of which have little to do with the neck tension of a cartridge case and this being a shooting forum I figure it is best to focus on what we commonly call neck tension or bullet hold. As long as we understand what it is and share the same channel I doubt it matters what we choose to call it. While SAAMI provides the above definition they make no mention of how to measure it or the units of measure.

Using a load cell we can measure both compression (force required to seat a bullet) and tension (force required to pull the seated bullet) as expressed in PSI (Pounds Square Inch) or for our metric friends Pascals.

Now does anyone have a clue the force required to break away and pull for example a .308 Winchester round or .223 Remington? With the same neck thickness would all .308 or .224 diameter bullets be the same? I have no idea?

What I do figure is this. As the tension becomes more and more uniform the group sizes should get smaller. Like anything else with a hand or for that matter factory loaded round the more uniform and consistent everything is the more uniform and smaller the resultant groups.

As to all the chatter involving engineers or engineering? To measure neck tension or bullet seating depth and do it accurately you will need a Mechanical type and for the data acquisition you will need an Electrical type. That or a hell of a good tool and die maker and a hell of a good electronics technician.

Ron

Mulligan

Silver $$ Contributor

Sometimes, identifying the problem takes effort, more for some than others. The ability to see through clear lenses is a real gift.Engineers can be indispensable....but they tend to think that because they have a "hammer" that every thing is a nail, or that because their calculations are complicated that they have visualized the problem correctly. All in all, the guys that are the best that I have seen at solving on the ground, get the job done sorts of problems have not been engineers. On the other hand when you need one, nothing else will do.

To the handloader, the ability to see/identity cause and effects and accept these while not fully understanding what happened is a greater gift.

For those in presuit of raw precision, indispensable.

CW

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.