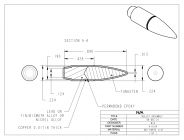

How do you swage a bullet with a hard tip inside the core? I called Federal Ammunition and talked to them about the M855, which they said they drop the steel tip into the tubing, then the lead core, and swage it all at once and that makes the M855 bullet. But when I was talking to Corbin's, he doesn't think my bullet could do that. Below is the drawing of it with basic dimensions, the abilities of it haven't been proven nor the legality of it, so DON'T make one unless you want to assist with making a prototype for the ATF. A variant of this will be on the market if everything goes well hopefully by the end of the year (2022).

But see how it has a tungsten tip? If I have the tip machined to shape, ie the shape of the die but not as wide or long, would that work without breaking the die? I can't use plating because the two halves aren't compatible. What can I do to be able to swage this?

But see how it has a tungsten tip? If I have the tip machined to shape, ie the shape of the die but not as wide or long, would that work without breaking the die? I can't use plating because the two halves aren't compatible. What can I do to be able to swage this?