Artisan

Life is an Equation, incapable of solution.

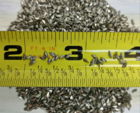

Don't know how these will work for cleaning out the primer pockets or if they will get stuck in any of the different size cases I process. Here's what they look like.

Magnetic SS chips. The commercial brass cleaners use these.

Something else I was wondering, the manufacturers of these wet pin tumblers put timers on them, but more importantly why didn't they put a speed adjuster (potentiometer) on the different models. I've added one to mine because it spins to fast when using dry media in it.

More food for thought. When getting into wet tumbling, I pondered the drying process. Heard from many, on all the way possible. I did use my wife's food dehydrator, which worked really well since it is a commercial model with metal shelves. But found the boiling hot water faster with less machines or mess or time involved.

I had considered making an air dryer for the wet brass. For about $50-$75 one can make a real nice model which will last for quite some time. I've only seen one, but it was to small and only did 50 cases at a pop. My thought was similar.

Build the frame out of light weight aluminum angle. Easy to work with and cut to fit. Use 4 small square plastic loading case holders. So you can still use them for loading (dual purpose). The ones which are square, small and hold 50 cases. Drill about a 1/4" hole all the way through, in the middle of the hole which holds the case in the tray. The trays should have holes on both sides for every case imaginable. The drilled hole is for air flow to go through the case. Make the frame to set 4 of the 50 cases trays as close together as possible. Under the trays, mounted to the frame will be 4-140mm computer case fans, which run on 12 volts. The 140mm fan is almost the same size as the loading trays. The fans, splitter and converter can be bought at Newegg.com. Take and wire the 4 fans to a fan controller which will control at least 4 fans. This way you can adjust the speed of drying with the fans. The fan controller will wire to a converter, to convert the 12 volt to 110 volt, to plug in any house receptacle. I was once going to manufacture these but I would have had to sell them for about $100 plus add shipping. Didn't think there would be a market for them. You would be able to air dry 200 cases at a time for pennies with the 12 volts and still use the 4 trays for hand-loading, since they just sit there and not attached to anything. The 140mm fans are super quiet, so not really much noise to speak of. They can be bought in a 4-pack also. The fans mounted underneath the trays will blow the air up through the drilled holes and into the cases, either the primer hole or if you can mount neck down, it might be a plus?

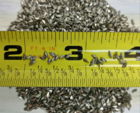

Magnetic SS chips. The commercial brass cleaners use these.

Something else I was wondering, the manufacturers of these wet pin tumblers put timers on them, but more importantly why didn't they put a speed adjuster (potentiometer) on the different models. I've added one to mine because it spins to fast when using dry media in it.

More food for thought. When getting into wet tumbling, I pondered the drying process. Heard from many, on all the way possible. I did use my wife's food dehydrator, which worked really well since it is a commercial model with metal shelves. But found the boiling hot water faster with less machines or mess or time involved.

I had considered making an air dryer for the wet brass. For about $50-$75 one can make a real nice model which will last for quite some time. I've only seen one, but it was to small and only did 50 cases at a pop. My thought was similar.

Build the frame out of light weight aluminum angle. Easy to work with and cut to fit. Use 4 small square plastic loading case holders. So you can still use them for loading (dual purpose). The ones which are square, small and hold 50 cases. Drill about a 1/4" hole all the way through, in the middle of the hole which holds the case in the tray. The trays should have holes on both sides for every case imaginable. The drilled hole is for air flow to go through the case. Make the frame to set 4 of the 50 cases trays as close together as possible. Under the trays, mounted to the frame will be 4-140mm computer case fans, which run on 12 volts. The 140mm fan is almost the same size as the loading trays. The fans, splitter and converter can be bought at Newegg.com. Take and wire the 4 fans to a fan controller which will control at least 4 fans. This way you can adjust the speed of drying with the fans. The fan controller will wire to a converter, to convert the 12 volt to 110 volt, to plug in any house receptacle. I was once going to manufacture these but I would have had to sell them for about $100 plus add shipping. Didn't think there would be a market for them. You would be able to air dry 200 cases at a time for pennies with the 12 volts and still use the 4 trays for hand-loading, since they just sit there and not attached to anything. The 140mm fans are super quiet, so not really much noise to speak of. They can be bought in a 4-pack also. The fans mounted underneath the trays will blow the air up through the drilled holes and into the cases, either the primer hole or if you can mount neck down, it might be a plus?