Several people mentioned sorting your bullets by bearing surface. I don’t know if I want to do that or not, but I would like to learn how you are measuring that.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sorting Bullets

- Thread starter gilream

- Start date

Ned Ludd

Silver $$ Contributor

One way is to use two caliper inserts at the same time. Depending on the type/brand of inserts used, it's questionable whether that is really an "accurate" measure of bearing surface length, but it may be sufficient for sorting purposes. The closer the diameter of the caliper insert holes are to caliber, the better the measurement will be.Several people mentioned sorting your bullets by bearing surface. I don’t know if I want to do that or not, but I would like to learn how you are measuring that.

Check out post #7 & #13 for a demo pic. Your basically checking the run out on the barring surface of the bullet, for run out on a concentricity gauge, set up for just the bullet. Keep in mind, that with VLD and Hollow Point bullets that, the bigger issues is with the Metplat. You can have a perfectly squared barring surface with a damaged Metplat also.. Check out SensorTube on this subject, there were some good video on this subject. Provided that they have not been demonized yet. There should be several threads here on Accurate Shooter in the archives also. I'm hoping someone with more of an insight on this subject, chimes in. I just check the ones that stand out when I'm sorting by CBTO and weight. With the way that the Sinclair Bullet Sorting Stand works... If there is a bullet that is bent, it will show up on the Dial gauge. Just my findings on my experimentsOne way is to use two caliper inserts at the same time. Depending on the type/brand of inserts used, it's questionable whether that is really an "accurate" measure of bearing surface length, but it may be sufficient for sorting purposes. The closer the diameter of the caliper insert holes are to caliber, the better the measurement will be.

that I have done. I hope some one else, has a better way of doing it, and they have been keeping it a secret.

I by far, do not have all the answers, and I'm here to learn also. So, some one with more experience on this subject, Please, now is the time to let it all out.

Edited 01/22/2021:: Post #7 pic is showing the measuring of the barring surface on the Sinclair bullet sorting stand.

Post #13 pic is showing the Neco checking bullet run out on the Barring surface for out of roundness.

Last edited:

Agreed, some people forget that it is just a reference point. For each Reloader, it boils down to his measuring sticks and his comparators, and Scales.One way is to use two caliper inserts at the same time. Depending on the type/brand of inserts used, it's questionable whether that is really an "accurate" measure of bearing surface length, but it may be sufficient for sorting purposes. The closer the diameter of the caliper insert holes are to caliber, the better the measurement will be.

Last edited:

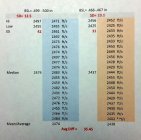

It's good to see that I'm not the only one that has mad methods. Great job, SirIf there's enough difference in the bearing surface, it can make a difference as I found it did with ~.034 spread . . .

View attachment 1230501

View attachment 1230502 View attachment 1230503

View attachment 1230505 View attachment 1230506

Similar threads

- Replies

- 2

- Views

- 1,113

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.