You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sophomore Questions as Shop gets Busy

- Thread starter INTJ

- Start date

LVLAaron

Gold $$ Contributor

No chip tray seems like a bad idea

Yeah. I'm confused.

No pull out tray ..you have access in the back to sweep out the chips. But yes, pull out chip is much better for someone with OCD about keeping things cleanYeah. I'm confused.

Dusty Stevens

Shiner

But is there a tray down there to catch the oil and such?

It looks like the stand is backwards and the tray is just not installed. I'm sure we're missing something.

No chips and oil don’t just spill on the floor. This is the only pic I still had that showed underneath bed….oil still drains to the rear coolant pump. Access to get the chips is from the rear, but I mostly would get them from the front. I don’t let chips build up more then one day at a time.

I don’t own that lathe anymore.

I did my first short barrel today, 16.5". I threaded the muzzle using the Viper fixture. It works okay, but wasn't as happy with .050" cuts as it was .020" cuts.

After the muzzle was threaded, I threaded on my 10" barrel extension. I used about five wraps of teflon tape. Then I chambered using the inboard and outboard spiders and flush. It worked well. I was able to get a nice tight dial in and had no leaks.

I think a delrin busing would be a better option than the Viper for muzzle threads, if I could ever find time to make some. I left the Viper on the 4-Jaw when I removed it from the lathe, though it's wasn't terrible dialing in the Viper.

After the muzzle was threaded, I threaded on my 10" barrel extension. I used about five wraps of teflon tape. Then I chambered using the inboard and outboard spiders and flush. It worked well. I was able to get a nice tight dial in and had no leaks.

I think a delrin busing would be a better option than the Viper for muzzle threads, if I could ever find time to make some. I left the Viper on the 4-Jaw when I removed it from the lathe, though it's wasn't terrible dialing in the Viper.

LVLAaron

Gold $$ Contributor

I did my first short barrel today, 16.5". I threaded the muzzle using the Viper fixture. It works okay, but wasn't as happy with .050" cuts as it was .020" cuts.

After the muzzle was threaded, I threaded on my 10" barrel extension. I used about five wraps of teflon tape. Then I chambered using the inboard and outboard spiders and flush. It worked well. I was able to get a nice tight dial in and had no leaks.

I think a delrin busing would be a better option than the Viper for muzzle threads, if I could ever find time to make some. I left the Viper on the 4-Jaw when I removed it from the lathe, though it's wasn't terrible dialing in the Viper.

I built a viper/gretan jig clone. I used it once. Stuff moves. It's parts sticking out of parts. I'm sure you could make it work with a ton of really light cuts, but I never liked it... because I knew how easy it was to move stuff.

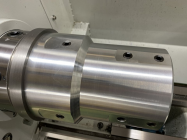

I immediately got to work on this:

I've done a number of short barrels in this and I can't recommend the design enough. You can build one in a day.

I built a viper/gretan jig clone. I used it once. Stuff moves. It's parts sticking out of parts. I'm sure you could make it work with a ton of really light cuts, but I never liked it... because I knew how easy it was to move stuff.

I immediately got to work on this:

View attachment 1389783

I've done a number of short barrels in this and I can't recommend the design enough. You can build one in a day.

Yours is indeed done right, with a direct mount to the base plate, and looks very nice. But what about your design makes it hold better than the Viper?

Dusty Stevens

Shiner

Its got the same contact points on the barrel no matter if its a 10 or 36” lathe, but to answer your real question no, the outboard spider will be more rigid than holding one spotWould a TBAS or viper style fixture on a 16x40" 4000lb machine with a D1-8 and 80mm spindle have as much rigidity as a small 13/14x40" 1500lb machine running an outboard spider?

LVLAaron

Gold $$ Contributor

Yours is indeed done right, with a direct mount to the base plate, and looks very nice. But what about your design makes it hold better than the Viper?

The viper style jig can move in the chuck.

Similar threads

- Replies

- 69

- Views

- 3,055

- Replies

- 40

- Views

- 2,631

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.