First of all before I start, I want to thank members LCazador, gotcha, Hopkins, and most importantly zfastmalibu for this perfect tip as to why my shoulder bumps were so inconsistent. Here is the proof as to how it solved my problem. For those that missed my original thread detailing my problem, it is here:

http://forum.accurateshooter.com/index.php?topic=3789175.0

I received the Redding Competition shell holders in the mail today from Midway and went to work on 48 pieces of brass that I have on hand that I had previously FLR with the Redding Type S Bushing FL sizer die. Again, these were LC09 223 brass fired once in my rifle’s Wyde-chamber.

At the start of the study, the headspace of each piece of brass was measured with a Miutoyo digital caliper using a Hornady L&L headspace gauge. I measured each piece of brass three times, pulling the case out of the gauge and rotating it before measuring it again. The measurements were very consistent, mostly the same number to the 0.0005†and worse case was about 1 thousands off.

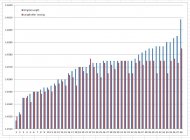

The results can be seen in this graph which shows the average headspace of the brass before resizing (blue bars). I have sorted the results with the original lengths using Excel from short to long to make it easier to intrepret. The shortest piece was 1.4527†and the longest 1.4608â€. The average headspace length was 1.2570â€, ES= 0.0082â€, and SDEV= 0.0017â€. So quite a bit of inconsistent shoulder bump as per my OP in the other thread.

Each piece of brass was then reized using same Redding Type S Bushing FL sizer die but now using the 0.010†Redding Competition shell holder. Before resizing, I notice that with the original Lee shell holder, the Type S sizing die actually touch the shell plate if there was no case in the die. The contact was good enough to prevent a piece of paper from being released if it was placed between the die and the shell holder. However, once a piece of brass was being sized, the bottom of the shell holder was clearly not touching the shell holder as a significant amount of the case can be seen in the gap between the bottom of the die and to top of the shell holder. With the Redding Competition shell holder in place and adjusted as per the die’s instructions (turn die down until it touch the shell plate and then add an extra ¼ turn), no space between the die and shell plate was visible during resizing and one can feel that cam-over effect at the bottom of the resizing cycle.

Each case was lube with Imperial sizing wax on the body but not the neck. The brass is very clean as it had been previously cleaned with SS media. The die was also cleaned so that its internals was spotless. The brass was resized using the die and now the new Redding Competition shell holder once, holding the handle down for a 5 second count at the bottom of the cycle.

The headspace of each piece of brass was then re-measured three times using the technique described above. The length of the cases are represented by the red bar. You will see pairs of blue and red bars in the graph representing each piece of brass before and after resizing. I resize all the brass regardless of length. Brass samples shorter than 1.4570†were in general unaffected by the resizing, losing 0.0005†on average. Most of the brass samples longer than 1.4570†were reduced in length on the average to 1.4571†with an ES=0.0023†and an SDEV= 0.0005â€. The ES was affected mostly by small number of outliers with sample #48 being the most extreme. Without sample #48 ES=0.0015†which is well within the tight headspace distribution I was looking for. The span of 1.5 thousands is in part my inability to measure reproducibly to the 0.5-1.0 thousands and also probably by a slight variation in annealing. The sample #48 was likely a good sample of work harden brass that was not annealed properly. It would not size down to less than 1.4580†even after two separate tries.

So I think my shoulder bumping problem is solved and I thank the board members again for their suggestions and help.

http://forum.accurateshooter.com/index.php?topic=3789175.0

I received the Redding Competition shell holders in the mail today from Midway and went to work on 48 pieces of brass that I have on hand that I had previously FLR with the Redding Type S Bushing FL sizer die. Again, these were LC09 223 brass fired once in my rifle’s Wyde-chamber.

At the start of the study, the headspace of each piece of brass was measured with a Miutoyo digital caliper using a Hornady L&L headspace gauge. I measured each piece of brass three times, pulling the case out of the gauge and rotating it before measuring it again. The measurements were very consistent, mostly the same number to the 0.0005†and worse case was about 1 thousands off.

The results can be seen in this graph which shows the average headspace of the brass before resizing (blue bars). I have sorted the results with the original lengths using Excel from short to long to make it easier to intrepret. The shortest piece was 1.4527†and the longest 1.4608â€. The average headspace length was 1.2570â€, ES= 0.0082â€, and SDEV= 0.0017â€. So quite a bit of inconsistent shoulder bump as per my OP in the other thread.

Each piece of brass was then reized using same Redding Type S Bushing FL sizer die but now using the 0.010†Redding Competition shell holder. Before resizing, I notice that with the original Lee shell holder, the Type S sizing die actually touch the shell plate if there was no case in the die. The contact was good enough to prevent a piece of paper from being released if it was placed between the die and the shell holder. However, once a piece of brass was being sized, the bottom of the shell holder was clearly not touching the shell holder as a significant amount of the case can be seen in the gap between the bottom of the die and to top of the shell holder. With the Redding Competition shell holder in place and adjusted as per the die’s instructions (turn die down until it touch the shell plate and then add an extra ¼ turn), no space between the die and shell plate was visible during resizing and one can feel that cam-over effect at the bottom of the resizing cycle.

Each case was lube with Imperial sizing wax on the body but not the neck. The brass is very clean as it had been previously cleaned with SS media. The die was also cleaned so that its internals was spotless. The brass was resized using the die and now the new Redding Competition shell holder once, holding the handle down for a 5 second count at the bottom of the cycle.

The headspace of each piece of brass was then re-measured three times using the technique described above. The length of the cases are represented by the red bar. You will see pairs of blue and red bars in the graph representing each piece of brass before and after resizing. I resize all the brass regardless of length. Brass samples shorter than 1.4570†were in general unaffected by the resizing, losing 0.0005†on average. Most of the brass samples longer than 1.4570†were reduced in length on the average to 1.4571†with an ES=0.0023†and an SDEV= 0.0005â€. The ES was affected mostly by small number of outliers with sample #48 being the most extreme. Without sample #48 ES=0.0015†which is well within the tight headspace distribution I was looking for. The span of 1.5 thousands is in part my inability to measure reproducibly to the 0.5-1.0 thousands and also probably by a slight variation in annealing. The sample #48 was likely a good sample of work harden brass that was not annealed properly. It would not size down to less than 1.4580†even after two separate tries.

So I think my shoulder bumping problem is solved and I thank the board members again for their suggestions and help.