Does the rim of the case fit all the way into the shellholder? if the shellholder has a bit of dirt or metal in it, the case will be off center and cause this. Ditto for the shellholder fitting into the press properly and being perfectly centered.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sizing process ruining brass

- Thread starter 59f100292

- Start date

Does the rim of the case fit all the way into the shellholder? if the shellholder has a bit of dirt or metal in it, the case will be off center and cause this. Ditto for the shellholder fitting into the press properly and being perfectly centered.

It does appear one sided.OP may have already done this ,but anytime I have something a little funky start going on will stop and clean dies,shellholders etc. plus gives you a chance to let the gobblins calm down lol.

Forgive me, LCD? Trebly?I'd be very tempted to ditch your current dies and get a LCD.

As this is a trebly there's hardly any need for FL sizing. I never bother for .223 running 50gr varmint loads.

Rim seems to fit fine. The co-ax has the two clamping plates, and they seem to close as always.Does the rim of the case fit all the way into the shellholder? if the shellholder has a bit of dirt or metal in it, the case will be off center and cause this. Ditto for the shellholder fitting into the press properly and being perfectly centered.

Forgive me, LCD? Trebly?

LCD=Lee Collet Die (it is a neck only sizing die)

Trebly=Referring to your .222 caliber

Just reread post and would add Ive never seen an le wilson die with tooling marks so maybe just a bad die got buy QC..

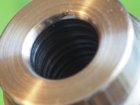

attached. Took the best pics I could, tough to take pics internally. The first pics from a side angle show the marks, but make it look worse than it is honestly. I tried to take one down the bore to show overall its polished fairly smooth.

Attachments

I would cast that chamber and see what you really have. Maybe you have a 222-1/2 or some other tweaked variation.

How much difference in diameter is that brass before/after sizing just above that line?

next time i have a set to size I'll take a few measurements

From the die instructions-

On the flip side, if your cases are being sized too much, then you may have an oversized chamber and we will need to open up your die to suit your guns chamber. Contact support@lewilson.com

Do yon have a different press then the Forster Co-ax, to try.

This may be the answer. I haven't cracked the instructions since the first time I bought the die. Forgot about that option. I do have a rockchucker here I will try next time. I never really suspected the coax as it works great with the dozen Redding-S sizers I use. Seems to be specific to this chamber and die.

I would try a different brand of brass.Yea new lot of lapua when I picked up the rifle.

I’ve never seen any type of die look like thatattached. Took the best pics I could, tough to take pics internally. The first pics from a side angle show the marks, but make it look worse than it is honestly. I tried to take one down the bore to show overall its polished fairly smooth.

bozo699

Gold $$ Contributor

So figure out how to get the die in a drill, then take some 400 grit sandpaper and polish the inside bottom part of the die. That's what I did to fix my issue but be careful. I wound up buying a lathe and a milking machine to make that kind of stuff easier.....

I love auto correct!.....so what kinda

“Milking machine” did ya buy? Lol

Wayne

bozo699

Gold $$ Contributor

First two are a new Wilson die it’s very smooth!

Next is a new Redding both dies were brand new both for 6 creedmoor

and a new one I just received in the mail today a Redding full length die in 6 creedmoor

It appears to me Redding comes much rougher from the factory than Wilson. when I get to my loading room I’m gonna check out forester and Whidden finishes

Wayne

Next is a new Redding both dies were brand new both for 6 creedmoor

and a new one I just received in the mail today a Redding full length die in 6 creedmoor

It appears to me Redding comes much rougher from the factory than Wilson. when I get to my loading room I’m gonna check out forester and Whidden finishes

Wayne

Attachments

-

82D111FE-4556-4ED4-8963-ED7B4A08DA78.jpeg63.8 KB · Views: 143

82D111FE-4556-4ED4-8963-ED7B4A08DA78.jpeg63.8 KB · Views: 143 -

3E95C3FB-1B86-4D48-928F-C0F5F7C7C1EF.jpeg72 KB · Views: 138

3E95C3FB-1B86-4D48-928F-C0F5F7C7C1EF.jpeg72 KB · Views: 138 -

144CB15F-D829-4D01-98CC-65A2F3E39AF3.jpeg164.1 KB · Views: 129

144CB15F-D829-4D01-98CC-65A2F3E39AF3.jpeg164.1 KB · Views: 129 -

97D9BF85-ABAA-40D8-92FB-EFC65F649287.jpeg63.7 KB · Views: 131

97D9BF85-ABAA-40D8-92FB-EFC65F649287.jpeg63.7 KB · Views: 131 -

04FB640E-406D-48B1-A7BF-7DFC3C63F13F.jpeg155.8 KB · Views: 124

04FB640E-406D-48B1-A7BF-7DFC3C63F13F.jpeg155.8 KB · Views: 124

I love auto correct!.....so what kinda

“Milking machine” did ya buy? Lol

Wayne

Precision Matthews 833T. I installed power feeds and have the DRO in the box. The cows will never know what hit them............

bozo699

Gold $$ Contributor

Precision Matthews 833T. I installed power feeds and have the DRO in the box. The cows will never know what hit them............

Thats a nice machine buddy.

Wayne

The rifle is an old BR rifle I purchased used in .222. Not a factory build, or more importantly not a factory chamber.

The sizing die is an LE Wilson. full length bushing die.

Using imperial Sizing die wax like always.

During sizing, the die is pushing/shaving brass material towards the base, leaving a sharp rim protruding at what would be the furthest most contact circumference between the die and brass. It is noticeable following low pressure loads, and can be enough to ruin the brass (new formed ridge/belt won't chamber) following higher pressure loads where the case is expanding.

The die appears to have a nice chamfer at the opening, so I do not believe the die has an excessively sharp edge that is digging in.

It is my only .222 so I can't try the die on brass coming out of another rifle. The Die is my only .222 sizer so I can't try a different die. It is my only LE wilson sizer, all my past experience has been Redding Type S.

My question is whether anyone has experience with similar symptoms. What is the cause? loose chamber, or tight die? Do I need a setback and rechamber or a new die? Bad lot of brass? (lapua, only purchased 100)

I purchased the rifle with a documented 872 shots through the barrel, and was given all the shooters notes, and there's no mention of sizing issues. This leads me to think there's a Die issue. The fact that it the results seem to correlate to load pressure and therefore case expansion leads me to believe its a loose chamber.

TIA

Bore scope. Inspect the chamber for crappy machining or tool damage.

The inside of your die looks extremely rough and I would say what is causing it to grip and push the brass and form the rings.

Below is the inside finish of a Forster full length die.

And below your die that needs to be returned to the factory.

I'd say Uncle Ed nailed it.

Similar threads

- Replies

- 30

- Views

- 1,273

- Replies

- 14

- Views

- 2,311

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.