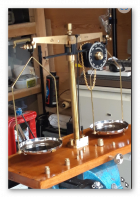

"As I understand the operation - turning the adjuster (3) counter clockwise ie. raising it (raising the CofG) will make the balance more sensitive and less stable and will give more deflection for any given weight."

Absolutely agree principally -- I also guessed it. But "facts are stubborn things" -- deflection decreased..

And I don't understand, why..?

Maybe, I will try it again.. but a little bit afraid of making it worse...

Absolutely agree principally -- I also guessed it. But "facts are stubborn things" -- deflection decreased..

And I don't understand, why..?

Maybe, I will try it again.. but a little bit afraid of making it worse...