Here is some data I saved a few months ago from a discussion of case weight vs volume. I did NOT collect the data; however, I took the posted data and made this graph. There are five different brands of brass here. If you look at the trend lines, you can see that two of them show a negative correlation between weight and volume. In other words, the heavier the piece of brass, the greater the volume. That goes against conventional wisdom. The other three behave as expected; i.e. the heavier the case, the lower the volume. One sample shows a very strong relationship between weight and volume, the other two not quite as much. Of course, since this is the Internet, you have to ask yourself how careful the experimenter was with his measurements. I can't vouch for that, but I'm tossing out this graph anyway.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Savage 12FV in 223 Rem Accuracy Experiences

- Thread starter SlowSqueeze

- Start date

I'm a guppy here, but it seems to me that case volume may not have noticeable effects on performance. ......... snip............

You may be correct, but that might depend on the definition of "noticeable", to paraphrase one ex-President.

Here is some data I collected. Some time ago I measured the water capacity of several samples of my .223 Lapua brass. The H2O water volume varied by a little less than 1% and this volume varies with the case weight. But does that matter? The short answer is that I'm not sure, but I think it might.

I shoot F-class and I do enough testing to know that actually proving a performance difference between light and heavy brass caused by variations in volume is a fools errand.

I'm convinced that changes in performance caused by annealing every time vs every 5th or 10th time are bound to be very small. But that doesn't mean annealing isn't worth doing. I anneal every time. I also weight sort bullets, neck turn my cases, uniform my primer pockets, deburr (or at least inspect) flash holes, chamfer case necks, and all the other steps most competitors perform. I stop short of weight sorting primers.

Anyway, since most of us test by shooting bullets over some significant range through an unknown atmosphere out of a gun with an unknown barrel temperature which is held by a human, etc. etc. etc. it is no surprise that any change in performance caused by uniforming a primer pocket, for example, as opposed to leaving it alone will be lost in the noise associated with the way we collect data.

Nevertheless, I'm convinced that all these tiny performance improvements, even if they're only theoretical, probably add up to improve performance at the target. Just because I can't prove something doesn't mean it isn't real.

Having said all that, I took a look at my latest Quickload .223 recipe this morning and changed the case volume by 1%. The calculations showed a change in MV from 2948 fps to 2936 fps, not very much. I took those two figures and plugged them into my ballistics app. At 600 yards, Quickload claims that the slow bullet will impact one inch lower. Again that's not much, but ask any F-class competitor if he would like to reduce his vertical by one inch and you will get a unanimous YES. Remember, the X ring is only 3" in diameter.

So I weight sort my brass into three lots, light, medium, and heavy. Since F-class matches usually consist of three strings of 20 rounds, I segregate the brass so that even though every round may not be the same, all 20 rounds in each string are as uniform as possible, or to tell the truth they're as uniform as I think reasonable. You gotta' draw the line somewhere.

I hope that by sorting my brass I can reduce the vertical dispersion at 600 yards caused by case volume from one inch to something less, maybe 1/2 inch or even 1/3 inch. Will that help? I believe it might because 1/2" is roughly 10% of my total vertical dispersion. A 10% improvement in any area is probably worth making.

I won the match last weekend tied in points with the 2nd place guy because I shot one more X than he did. And I've lost matches by that amount too.

Of course, your mileage may vary, but I'm going to continue to weight sort my brass for F-class matches.

I’m with you man- there are a lot more important factors to account for before we get to the small differences due to case volume. That being said, one dream of mine is the peel back the layers of variables that lead to variation (i.e. precision, not necessarily accuracy). Once we have the data in hand it should be pretty easy to do a cost-benefit prioritization, and an effort-benefit prioritization. For now I’m just cataloging what I know/believe are things to think about based on my research and plinking to date.I'm a guppy here, but it seems to me that case volume may not have noticeable effects on performance.

I would think that, in the real world, minor variations in case length, weight of propellent, variations of brass hardness, variation in bullet bearing surface, variation in primer burning, variation in the lay of individual kernels in the case, ambient temperature shifts, etc. would have as much or more effect on performance than case volume.

JMHO.

There’s a part of my head, and not my favorite part either, that is compelled to find the end of the rabbit hole. I am wired to want to know what makes the world tick, and when it comes to shooting, I want to know what made a bullet hit 1/16” higher than another.Great read. Thank you for posting.

I always tell guys that tell me they are interested in reloading to figure out how far down the rabbit hole they are willing to go. Regardless of whether or not you want to dance on the edge or go scrambling fully down, it's still a rewarding process. I simply poke my nose in just past the rim. I started to head further down and then realized that for me, it's not fun. So I sold my comparators and such and I just do some case prep and shoot. For my shooting, it's plenty. And, my guns shoot well enough for me to have a good time. However I'm glad that there are guys like you in the world, as going further in benefits the community as a whole.

It’s exhausting at times, and I’ve had more than one ‘overheat’ about various minutia, but when it’s all said and done, and I’m slowly squeezing (<- hence my user name) that trigger there is a sense of euphoria that in some small way I have figured out a part of the universe. Sharing back and forth with y’all makes it that much sweeter.

That being said, I do get a kick out of machining tiny 223 cases to absurd tolerances (sick, I know). I probably spend ⅓ of my time reading/researching, ⅓ preparing my loads, and ⅓ of my time actually shooting. As you rightly point out- it’s about having fun, and that’s fun for me (in a twisted way). So sit back, grab a drink, and enjoy watching me run deeper.

Oh, and make sure to enjoy the extra ⅔ of your time shooting! LOL

Thanks for sharing the plot! After I saw this post I searched around a bit on the topic and found this thread (also on AccurateShooter):Here is some data I saved a few months ago from a discussion of case weight vs volume. I did NOT collect the data; however, I took the posted data and made this graph.

http://forum.accurateshooter.com/threads/measuring-case-internal-volume.3807241/

The thread has two OUTSTANDING graphs near the end that show the negative correlation between case weight and case volume. At this point I’ll take the relationship as fact and move on. I’ll respond to your second post individually next…

First off, thank you Mozella for the posts. I’m going to walk in your footsteps for now rather than dig too deeply down this fork in the rabbit hole!You may be correct, but that might depend on the definition of "noticeable", to paraphrase one ex-President.

Here is some data I collected. Some time ago I measured the water capacity of several samples of my .223 Lapua brass. The H2O water volume varied by a little less than 1% and this volume varies with the case weight. But does that matter? The short answer is that I'm not sure, but I think it might.

I might just be your guy (i.e. fool), but only after I work out the first 20 more impactful factors (some of which you point out in your post)....actually proving a performance difference between light and heavy brass caused by variations in volume is a fools errand.

I’ll take a variable that contributes 12 FPS to bullet velocity as a material factor any day. I’d prefer to have a bit more datum behind the number however, but it’s tough to argue with Quickload, especially when we are looking at ballpark concepts.Having said all that, I took a look at my latest Quickload .223 recipe this morning and changed the case volume by 1%. The calculations showed a change in MV from 2948 fps to 2936 fps, not very much.

In my last few handload sessions I weight sorted my brass in 1/10 grain increments. I shoot 5 round groups, not the 20 round lots for F-class. After pitching outliers (some of the PMC brass was close to 96 grains, with the lightest in the 89 range- that’s a LOT), I’d walk up the tape mark assembling case groups that were adjacent to the 1/10 of a grain. On a side note, one thing I did to mitigate pressure variation due to case volume was to load charges inversely with case weight- the lightest cases got the heaviest charges, and the heaviest cases got the lightest charges.So I weight sort my brass into three lots, light, medium, and heavy.

I don’t have any data to demonstrate the effect that this had on my loads, but that exercise was one of the critical turning points for me to take the full plunge into handloading.

One of Nutnfancy’s videos from shot show (I think 2015) included an interview with Stan Pate. Stan was talking about the mental aspect of F-Class, and when he’s ready to shoot if a negative thought enters his mind he’ll clear the chamber and pause for a minute to clear his mind.I hope that by sorting my brass I can reduce the vertical dispersion at 600 yards caused by case volume from one inch to something less, maybe 1/2 inch or even 1/3 inch. Will that help? I believe it might because 1/2" is roughly 10% of my total vertical dispersion. A 10% improvement in any area is probably worth making.

I haven’t shot F-class, but I’ve done a LOT of high stress things in my life and I am a HUGE believer in mental preparation. When I’m at the range my sense of comfort that I have prepared my loads well, and they are high quality, definitely helps me to be confident. I haven’t measured the actual contribution of my confidence on a given day, but I’m sure you believing that your prep helps, means it actually does.

Congrats on the win last weekend by the way! Maybe I’ll get out soon just to see...

Oh, and for the record, I will also continue weight sorting my brass in the same manner described above. More details will be posted when I go over my nuclear-powered hand loading process!

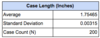

CASE LENGTH

The second of the case specific characteristics I’ll present for the PMC brass is the case length. I think this data is mostly presenting the effectiveness of the EZ trim tool, with some unknowns after firing the cases. Case length isn’t nearly as interesting to study as the case weight however- so long as the case is within SAAMI spec (1.74” to 1.76” total length), and fits my chamber, I don’t really care.

What I DO care about is the neck length however, and the length of the case is largely set by the length of the neck (assuming the case is sized correctly to the datum line, i.e. correct headspace). In other words, a long case means a longer case neck. A longer case neck used with a consistent bullet seating depth means some cases will grip the bullet with more brass than other cases that are shorter.

As the story goes, gripping a bullet with more force (that extra brass at the end of the neck) increases the case pressure during ignition, leading to higher muzzle velocity. I’ll talk a lot more about case necks later on- the case neck will get the lion’s share of my attention during the case preparation process because it is so critical to precision.

Here's the corrected histogram from Excel to replace the bad on (original).

Note: My histograms may be plotted in groups ("bins") of 0.0005". I do not actually have any measurement equipment that is capable of measuring in 1/10,000 of an inch. This is only done to get better plots.

The second of the case specific characteristics I’ll present for the PMC brass is the case length. I think this data is mostly presenting the effectiveness of the EZ trim tool, with some unknowns after firing the cases. Case length isn’t nearly as interesting to study as the case weight however- so long as the case is within SAAMI spec (1.74” to 1.76” total length), and fits my chamber, I don’t really care.

What I DO care about is the neck length however, and the length of the case is largely set by the length of the neck (assuming the case is sized correctly to the datum line, i.e. correct headspace). In other words, a long case means a longer case neck. A longer case neck used with a consistent bullet seating depth means some cases will grip the bullet with more brass than other cases that are shorter.

As the story goes, gripping a bullet with more force (that extra brass at the end of the neck) increases the case pressure during ignition, leading to higher muzzle velocity. I’ll talk a lot more about case necks later on- the case neck will get the lion’s share of my attention during the case preparation process because it is so critical to precision.

Here's the corrected histogram from Excel to replace the bad on (original).

Note: My histograms may be plotted in groups ("bins") of 0.0005". I do not actually have any measurement equipment that is capable of measuring in 1/10,000 of an inch. This is only done to get better plots.

Last edited:

CASE CONCENTRICITY

As a super brief introduction to concentricity (if you aren’t aware of it), concentricity measures how straight the case cylinder is- all cases have some deviation from being perfectly straight, and concentricity measures how much deviation is present. As an extreme example, bananas are not concentric (straight), and on a very small scale, measuring the concentricity is akin to measuring the banana-ness of cases. I measure case (and neck) concentricity with my RCBS concentricity gauge.

I wish I could provide more meaningful data about the body concentricity from the PMC cases, but right around where I was measuring concentricity, about ⅛” behind the shoulder, the cases would regularly deform. The deformation was usually a small divot, and was sufficiently large (about 45-60 degrees of rotation) to prevent me from getting an accurate reading.

What I was able to measure suggests that case concentricity is around 0.001”, and is pretty tight. From this limited data, I’ll assume for now that my chamber is relatively concentric, which I readily expect from Savage Arms anyhow.

As for the case deformation, ya, I pitched a lot of cases- especially the cases with a visible indentation. That’s bad juju for sure, and not the type of thing I want around 50,000+ pounds per square inch of pressure.

As a super brief introduction to concentricity (if you aren’t aware of it), concentricity measures how straight the case cylinder is- all cases have some deviation from being perfectly straight, and concentricity measures how much deviation is present. As an extreme example, bananas are not concentric (straight), and on a very small scale, measuring the concentricity is akin to measuring the banana-ness of cases. I measure case (and neck) concentricity with my RCBS concentricity gauge.

I wish I could provide more meaningful data about the body concentricity from the PMC cases, but right around where I was measuring concentricity, about ⅛” behind the shoulder, the cases would regularly deform. The deformation was usually a small divot, and was sufficiently large (about 45-60 degrees of rotation) to prevent me from getting an accurate reading.

What I was able to measure suggests that case concentricity is around 0.001”, and is pretty tight. From this limited data, I’ll assume for now that my chamber is relatively concentric, which I readily expect from Savage Arms anyhow.

As for the case deformation, ya, I pitched a lot of cases- especially the cases with a visible indentation. That’s bad juju for sure, and not the type of thing I want around 50,000+ pounds per square inch of pressure.

HEADSPACE

When I first started digging, and I mean really digging into reloading, headspace was, well, a head-scratcher for me. Everyone kept mentioning the ‘datum line’ on the case, which I couldn’t see or locate on the case. Sounds funny, and feel free to laugh along with me if you want to- but man it was a hard concept for me to get through my thick skull.

For the record, the datum line is a point on the shoulder that is used to set some of the most critical case parameters. I’m not sure if the datum line is really arbitrarily set, or if there are some calculations/geometry that determines its location beyond just picking the place where the shoulder is 0.330” thick (but that’s what it is). For 223 Remington ammunition the datum line is between 1.4666” (minimum) and 1.46700” (maximum) from the case head. And yes, the Sporting Arms and Ammunitions Manufacturers Institute (SAAMI) gave the datum tolerances with 10,000 thousandths of an inch accuracy.

Here’s the image right out of the SAAMI Manual (page 68 in the footer, or page 80 in the PDF).

If you notice, the page has two sections- top and bottom. The section above is the ammunition spec, and the section below is the chamber specification. The chamber headspace is slightly bigger than the ammunition: 1.4636” to 1.4736” (again, gotta love those 1/10,000!). It makes common sense that the chamber will be bigger than the ammunition- the round better be smaller in order to fit into the chamber…

The headspace numbers are shown on the chamber (bottom) figure with the crossed out circle icon (looks like a railroad sign). It's a little harder to point out on the case spec...

When I first started digging, and I mean really digging into reloading, headspace was, well, a head-scratcher for me. Everyone kept mentioning the ‘datum line’ on the case, which I couldn’t see or locate on the case. Sounds funny, and feel free to laugh along with me if you want to- but man it was a hard concept for me to get through my thick skull.

For the record, the datum line is a point on the shoulder that is used to set some of the most critical case parameters. I’m not sure if the datum line is really arbitrarily set, or if there are some calculations/geometry that determines its location beyond just picking the place where the shoulder is 0.330” thick (but that’s what it is). For 223 Remington ammunition the datum line is between 1.4666” (minimum) and 1.46700” (maximum) from the case head. And yes, the Sporting Arms and Ammunitions Manufacturers Institute (SAAMI) gave the datum tolerances with 10,000 thousandths of an inch accuracy.

Here’s the image right out of the SAAMI Manual (page 68 in the footer, or page 80 in the PDF).

If you notice, the page has two sections- top and bottom. The section above is the ammunition spec, and the section below is the chamber specification. The chamber headspace is slightly bigger than the ammunition: 1.4636” to 1.4736” (again, gotta love those 1/10,000!). It makes common sense that the chamber will be bigger than the ammunition- the round better be smaller in order to fit into the chamber…

The headspace numbers are shown on the chamber (bottom) figure with the crossed out circle icon (looks like a railroad sign). It's a little harder to point out on the case spec...

SAAMI 223 REMINGTON SPEC HEADSPACE ISSUE?

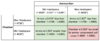

Someone please weigh in who knows this stuff better- as I understand it the minimum chamber headspace SHOULD ALWAYS be bigger than the maximum ammunition headspace (i.e. the round should always fit into the chamber, notice the theme...). Per the tolerances this doesn’t appear to be true, at least as I read them... The following table shows this a little better.

Do the SAAMI specs really allow for the possibility of ammunition being headspaced larger than the smallest tolerance on the chamber headspace as shown in the bottom right corner (highlighted in red)?!

Someone please weigh in who knows this stuff better- as I understand it the minimum chamber headspace SHOULD ALWAYS be bigger than the maximum ammunition headspace (i.e. the round should always fit into the chamber, notice the theme...). Per the tolerances this doesn’t appear to be true, at least as I read them... The following table shows this a little better.

Do the SAAMI specs really allow for the possibility of ammunition being headspaced larger than the smallest tolerance on the chamber headspace as shown in the bottom right corner (highlighted in red)?!

MY HEADSPACE MEASUREMENTS ARE HOSED!

On with the headspace for my rifle and ammo… I am using the Hornady Lock-n-Load Headspace Comparator, which I have found to be pretty handy- why my readings are messed up is driving me nuts though.

I never had a reason to verify my readings against the SAAMI specs with the headspace gauge, because things worked and I was largely shooting previously shot brass (which I know, ironically, also worked). So I compared my headspace on the PMC ammo and then measured the fired brass without much problem- they were within a thousandth or so. When I went to upload my average data just now I saw a problem…

Average Fired Brass Headspace: 1.45448” (measured with Hornaday comparator)

SAAMI Ammo Headspace Min Spec: 1.4596”

In other words, on average, my fired brass is measuring 0.00512” less than the min SAAMI ammunition spec! I would expect fired brass to the on the upper end of the tolerance, because the firing would push the case shoulder up to the chamber shoulder, and hence make the headspace larger. When I double checked the factory, unfired, PMC ammo, it measured right in line at around 1.454”. Hmmm… that’s not okay.

So I spent about 2 hours pouring over SAAMI specs trying to figure out what was going on. Then I got a strange thought- the SAAMI datum line is specified at a point where the shoulder is 0.330” in diameter, which should be exactly what my Hornady gauge hole diameter should be drilled/reamed to (hey, it’s engraved with “330” on it, why wouldn’t it be 0.330”?). So I got my calipers out and viola! 0.322” diameter. I will grant some error in the reading because my calipers aren’t that sharp on ID measurements, but I don’t think they are off by 0.008”!

The smaller diameter hole on my gauge could explain why my headspace measurements would be off. The problem with that however is a smaller diameter hole would make the reading LONGER because the case wouldn’t go into the gauge as far. I’m measuring short, and not a little short either- somewhere between 0.005” and 0.019”!

Oh, and for those not familiar with the Hornady tool- it is exactly 2" long (the red and aluminum colored pieces). I zeroed my calipers on the gauge before taking this reading, so the calipers indicate 3.454+. Subtracting the 2" for the gauge yields 1.454+" of headspace... See my problem?!

On with the headspace for my rifle and ammo… I am using the Hornady Lock-n-Load Headspace Comparator, which I have found to be pretty handy- why my readings are messed up is driving me nuts though.

I never had a reason to verify my readings against the SAAMI specs with the headspace gauge, because things worked and I was largely shooting previously shot brass (which I know, ironically, also worked). So I compared my headspace on the PMC ammo and then measured the fired brass without much problem- they were within a thousandth or so. When I went to upload my average data just now I saw a problem…

Average Fired Brass Headspace: 1.45448” (measured with Hornaday comparator)

SAAMI Ammo Headspace Min Spec: 1.4596”

In other words, on average, my fired brass is measuring 0.00512” less than the min SAAMI ammunition spec! I would expect fired brass to the on the upper end of the tolerance, because the firing would push the case shoulder up to the chamber shoulder, and hence make the headspace larger. When I double checked the factory, unfired, PMC ammo, it measured right in line at around 1.454”. Hmmm… that’s not okay.

So I spent about 2 hours pouring over SAAMI specs trying to figure out what was going on. Then I got a strange thought- the SAAMI datum line is specified at a point where the shoulder is 0.330” in diameter, which should be exactly what my Hornady gauge hole diameter should be drilled/reamed to (hey, it’s engraved with “330” on it, why wouldn’t it be 0.330”?). So I got my calipers out and viola! 0.322” diameter. I will grant some error in the reading because my calipers aren’t that sharp on ID measurements, but I don’t think they are off by 0.008”!

The smaller diameter hole on my gauge could explain why my headspace measurements would be off. The problem with that however is a smaller diameter hole would make the reading LONGER because the case wouldn’t go into the gauge as far. I’m measuring short, and not a little short either- somewhere between 0.005” and 0.019”!

Oh, and for those not familiar with the Hornady tool- it is exactly 2" long (the red and aluminum colored pieces). I zeroed my calipers on the gauge before taking this reading, so the calipers indicate 3.454+. Subtracting the 2" for the gauge yields 1.454+" of headspace... See my problem?!

Last edited:

RESOLUTION OF HOSED HEADSPACE MEASUREMENTS!

After scratching my head some more, getting a few glasses of wine, and then a good nights sleep I still can’t figure out what’s going on. So I put a call in to Savage Arms to see if they had any thoughts. For the record, Savage is great when you call the tech support line, so if you ever have an issue, give them a call.

After talking through my issue, the guy asked if I could have a burr or something in the way on the chamber. I told him I’m using fired cases (about 200 of them) and not looking at the chamber directly- besides if it was a burr I would have seen it imprint on my cases long ago. Savage didn’t have anything else to recommend as a possibility, so I consider this base covered. They did tell me, somewhat obviously, that they put chambers on the rifles in compliance with SAAMI specs, but feel short of giving me a specific measurement from their reamers.

So, next call is to Hornady…

Just like the Savage team, the folks over a Hornady are awesome to work with- I swear I could call the customer service line just to listen to the recording of the guy who gives the instructions for the automated system! Anyhow, when I explained what was going on, the answer was really straightforward (good, and not so good).

I have the Hornady Headspace COMPARATOR, which is NOT a gauge. The concept is the comparator will give you relative readings that are close, but not exact, to the headspace. So, if you measure factory ammo headspace (call it measure A), then fire the round and measure the brass (and take measure B), the comparison of the two readings is accurate- in other words, B - A = real headspace change, BUT A & B are not necessarily accurate headspace measures themselves.

So, thank you Savage Arms, and Hornady Manufacturing for straightening me out, and for being great people to talk to!

After scratching my head some more, getting a few glasses of wine, and then a good nights sleep I still can’t figure out what’s going on. So I put a call in to Savage Arms to see if they had any thoughts. For the record, Savage is great when you call the tech support line, so if you ever have an issue, give them a call.

After talking through my issue, the guy asked if I could have a burr or something in the way on the chamber. I told him I’m using fired cases (about 200 of them) and not looking at the chamber directly- besides if it was a burr I would have seen it imprint on my cases long ago. Savage didn’t have anything else to recommend as a possibility, so I consider this base covered. They did tell me, somewhat obviously, that they put chambers on the rifles in compliance with SAAMI specs, but feel short of giving me a specific measurement from their reamers.

So, next call is to Hornady…

Just like the Savage team, the folks over a Hornady are awesome to work with- I swear I could call the customer service line just to listen to the recording of the guy who gives the instructions for the automated system! Anyhow, when I explained what was going on, the answer was really straightforward (good, and not so good).

I have the Hornady Headspace COMPARATOR, which is NOT a gauge. The concept is the comparator will give you relative readings that are close, but not exact, to the headspace. So, if you measure factory ammo headspace (call it measure A), then fire the round and measure the brass (and take measure B), the comparison of the two readings is accurate- in other words, B - A = real headspace change, BUT A & B are not necessarily accurate headspace measures themselves.

So, thank you Savage Arms, and Hornady Manufacturing for straightening me out, and for being great people to talk to!

Last edited:

COMPARISON OF FIRED AND UNFIRED CASE HEADSPACE

Now that I have clarified my tool is suited for comparison, but not measurement, it’s time to go back and compare some cases and see what we get…

I used the comparator to get an average of 20 factory loaded PMC Bronze rounds, which came out to be 1.4548” (again, ignore the specific number for now). I then measured 20 fired cases that were unmolested after firing, and the average came out to 1.455075”.

The comparator is therefore telling me that the headspace of the ammo grew by a staggeringly low 0.000275” (1.455075” - 1.4548”). Seems odd to me that the Savage chamber is only ~3/10,000 of an inch larger than the factory ammo headspace, so the saga continues for now (until I get a real headspace gauge).

[EDIT]

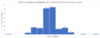

I decided to add a plot of my relative headspace measurements with the comparator. I excluded an axes label to avoid any confusion since these are only relative headspace readings and the specific number of inches measured isn't useful. The plot shows that the relative headspace is pretty tight- each bar represents 0.001" and is the best 'normal' distribution I've seen yet.

Now that I have clarified my tool is suited for comparison, but not measurement, it’s time to go back and compare some cases and see what we get…

I used the comparator to get an average of 20 factory loaded PMC Bronze rounds, which came out to be 1.4548” (again, ignore the specific number for now). I then measured 20 fired cases that were unmolested after firing, and the average came out to 1.455075”.

The comparator is therefore telling me that the headspace of the ammo grew by a staggeringly low 0.000275” (1.455075” - 1.4548”). Seems odd to me that the Savage chamber is only ~3/10,000 of an inch larger than the factory ammo headspace, so the saga continues for now (until I get a real headspace gauge).

[EDIT]

I decided to add a plot of my relative headspace measurements with the comparator. I excluded an axes label to avoid any confusion since these are only relative headspace readings and the specific number of inches measured isn't useful. The plot shows that the relative headspace is pretty tight- each bar represents 0.001" and is the best 'normal' distribution I've seen yet.

Last edited:

...... snip............

I’ll take a variable that contributes 12 FPS to bullet velocity as a material factor any day. I’d prefer to have a bit more datum behind the number however, but it’s tough to argue with Quickload, especially when we are looking at ballpark concepts.

In my last few handload sessions I weight sorted my brass in 1/10 grain increments. .......... snip.............

I don’t have any data to demonstrate the effect that this had on my loads, but that exercise was one of the critical turning points for me to take the full plunge into handloading.

............ snip...............

I agree, that a 12 fps MV variation means something, but you must also realize that all but the most avid target shooters would be happy with a muzzle velocity extreme spread of 12 fps, especially with the .223 cartridge which is notoriously difficult to tame when it comes to ES and SD. If a small change in MV is equal to what most folks find to be a very good ES, then how are you going to prove anything for certain? The change you're looking for is equal or less than the normal variation caused by other factors. I other words, the data gets lost in the noise. Yes, you can tease good information out of noisy data but it takes more than one five-shot group to do so............ much more.

So what I do is try to get a handle on what might make a difference and try to take a reasonable approach to exploit that variable in such a way that I hope it will improve the performance of my ammo even if I can't prove it. You may elect to collect data on exactly how small changes in case volume or slight differences in case weight actually effect your group sizes, but you'll be wearing out a lot of barrels and spending lots of time at the range trying to prove something which may not be provable, at least by the normal shooter using normal equipment.

Your post about mental attitude is germane. Going to a match with your "good stuff" which you KNOW will perform is important. If that batch of good ammo includes rounds which were made from weight sorted bullets, weight sorted brass, and so-on and so-on and if you believe that these small steps improve performance, then you're ahead of the game. If I'm shooting next to you and I use a dipper to measure my powder and seat those bargain blemished bullets, then I for one will not feel very confident about winning. You get the point.

Bottom line: Knowing that something is good is important even though you may not be able to prove it. I like your approach which seems to be an attempt to make sense of a lot of facts and figures. The more you study, the better you will do, but don't chase too hard in trying to prove something if the proof (assuming it exists) won't make a meaningful difference.

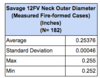

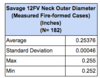

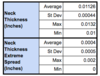

NECK OUTER DIAMETER

The neck outer diameter is one of the most important measurements I’ve taken on the fired cases. These measurements give me valuable information about the chamber that Savage Arms put into this nifty little 12FV, and I want to report, unlike the jacked up headspace measurements I was getting (only blaming myself here), the neck measurements for my chamber from the fired brass were a very tight 0.254”. That neck diameter is perfectly agreeable to the SAAMI specification. SAAMI specs specify a 0.002” tolerance on all diameter specs, meaning the neck diameter could be from 0.254” to as big as 0.256” (I’m not an expert on SAAMI though, so a note of caution that I might be misreading the spec). Here’s the data table for my neck OD measurements:

I would plot a histogram for you, but the tolerance is so tight it wouldn’t show much. You’ll have to wait for more eye candy. [EDIT] Changed my mind- here's the nice and tight histogram!

For the record, this is how I would expect most of the histograms to look- there is a gradual slope up to a tight maximum and then a very sharp fall back down to the X-axes. This makes sense because there is a maximum amount that a case neck can stretch in the rifle chamber (until it hits the chamber). Cases can stretch less, but they shouldn't really stretch much past that limit. So this is a well behaved characteristic- I can't really explain what the other plots are doing, but you can bet as I really clamp down on my measurements that I'll be digging in a LOT more!

In summary, all looks good with my chamber's neck- it's on the lower end of SAAMI chamber spec. There was low variation in the case necks. I'm guessing that the variation in neck size is largely due to variation in the thickness of the necks- which yields variation in the amount of fire-forming that takes place on individual cases. I'm turning necks later on, so all I really care to know for now is how my Savage 12FV neck diameter is configured. From the measurements I’ll take my chamber neck to be 0.254”, which is a pretty common 223 neck chamber diameter.

The neck outer diameter is one of the most important measurements I’ve taken on the fired cases. These measurements give me valuable information about the chamber that Savage Arms put into this nifty little 12FV, and I want to report, unlike the jacked up headspace measurements I was getting (only blaming myself here), the neck measurements for my chamber from the fired brass were a very tight 0.254”. That neck diameter is perfectly agreeable to the SAAMI specification. SAAMI specs specify a 0.002” tolerance on all diameter specs, meaning the neck diameter could be from 0.254” to as big as 0.256” (I’m not an expert on SAAMI though, so a note of caution that I might be misreading the spec). Here’s the data table for my neck OD measurements:

I would plot a histogram for you, but the tolerance is so tight it wouldn’t show much. You’ll have to wait for more eye candy. [EDIT] Changed my mind- here's the nice and tight histogram!

For the record, this is how I would expect most of the histograms to look- there is a gradual slope up to a tight maximum and then a very sharp fall back down to the X-axes. This makes sense because there is a maximum amount that a case neck can stretch in the rifle chamber (until it hits the chamber). Cases can stretch less, but they shouldn't really stretch much past that limit. So this is a well behaved characteristic- I can't really explain what the other plots are doing, but you can bet as I really clamp down on my measurements that I'll be digging in a LOT more!

In summary, all looks good with my chamber's neck- it's on the lower end of SAAMI chamber spec. There was low variation in the case necks. I'm guessing that the variation in neck size is largely due to variation in the thickness of the necks- which yields variation in the amount of fire-forming that takes place on individual cases. I'm turning necks later on, so all I really care to know for now is how my Savage 12FV neck diameter is configured. From the measurements I’ll take my chamber neck to be 0.254”, which is a pretty common 223 neck chamber diameter.

Last edited:

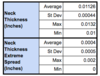

NECK CONCENTRICITY

Just like we checked the ‘banana-ness’ of the case body, we’ll check the bababa-ness of the neck itself. Case necks are so very important in precision- they have the thinnest brass on the case, are subjected to some of the most violent forces, are ‘worked’ more than other parts of the case, and do the critical job of holding the bullet. If the neck isn’t concentric, the bullet will hit the lands in a crooked manner during firing, which will never be corrected. If the neck IS pointing the bullet perfectly straight (i.e. perfectly concentric) but has variation in the neck wall thickness, then one side of the neck will hold the bullet tighter (and longer) than the opposing side, meaning the bullet will launch crooked and you’re back in the same boat with no recovery.

The only things you can do to foster neck concentricity is 1) turn your necks on a lathe, and 2) use high quality dies. Because the PMC cases I’m studying were not neck turned, and I used fair quality dies, there’s not much I could do in the past to control concentricity. But we are more focused on measuring my fire formed cases to get a peek at the chamber configuration- we’ll talk about case prep later. Not to belabor it longer, here’s the data for my PMC fire formed necks:

Average Concentricity: 0.0011507”

Standard Deviation: 0.0006137”

And here's a plot of the concentricity, which again shows that it's really tight.

So my fire formed case necks are usually about 1/1,000 of an inch out of concentric, and vary about ½ a thousandth for one standard deviation. Not bad for junky brass and fair quality sizing dies. Put a check next to the 12FV neck- she’s got a straight neck and will shoot well.

Just like we checked the ‘banana-ness’ of the case body, we’ll check the bababa-ness of the neck itself. Case necks are so very important in precision- they have the thinnest brass on the case, are subjected to some of the most violent forces, are ‘worked’ more than other parts of the case, and do the critical job of holding the bullet. If the neck isn’t concentric, the bullet will hit the lands in a crooked manner during firing, which will never be corrected. If the neck IS pointing the bullet perfectly straight (i.e. perfectly concentric) but has variation in the neck wall thickness, then one side of the neck will hold the bullet tighter (and longer) than the opposing side, meaning the bullet will launch crooked and you’re back in the same boat with no recovery.

The only things you can do to foster neck concentricity is 1) turn your necks on a lathe, and 2) use high quality dies. Because the PMC cases I’m studying were not neck turned, and I used fair quality dies, there’s not much I could do in the past to control concentricity. But we are more focused on measuring my fire formed cases to get a peek at the chamber configuration- we’ll talk about case prep later. Not to belabor it longer, here’s the data for my PMC fire formed necks:

Average Concentricity: 0.0011507”

Standard Deviation: 0.0006137”

And here's a plot of the concentricity, which again shows that it's really tight.

So my fire formed case necks are usually about 1/1,000 of an inch out of concentric, and vary about ½ a thousandth for one standard deviation. Not bad for junky brass and fair quality sizing dies. Put a check next to the 12FV neck- she’s got a straight neck and will shoot well.

Last edited:

SIZING MAY HINDER CONCENTRICITY!

One crazy thing that did pop up in Google Sheets while I was looking at the case neck OD is the following figure. The first 18 cases in my sample were, apparently, sized at some point and subsequently removed from the sample because their average neck diameter was 0.2459”, almost 0.008” smaller than the fired cases. Where Google Sheets helped to redeem itself (after the botched length histogram above which I subsequently replaced with Excel versions) was showing me this graph.

This graph is interesting because, even though the case neck size variation is smaller for the group on the left (it’s a smaller sample too), the concentricity is much, much worse. This tells me I have a problem with one of my sizing dies- either my Lee full-length die, or my RCBS neck sizing die. I don’t recall sizing the necks, so I can’t say which die it was. Whatever the case, be aware that your sizing dies can have unintended consequences for your brass, like making concentricity much worse, even though they are doing their jobs (sizing).

One crazy thing that did pop up in Google Sheets while I was looking at the case neck OD is the following figure. The first 18 cases in my sample were, apparently, sized at some point and subsequently removed from the sample because their average neck diameter was 0.2459”, almost 0.008” smaller than the fired cases. Where Google Sheets helped to redeem itself (after the botched length histogram above which I subsequently replaced with Excel versions) was showing me this graph.

This graph is interesting because, even though the case neck size variation is smaller for the group on the left (it’s a smaller sample too), the concentricity is much, much worse. This tells me I have a problem with one of my sizing dies- either my Lee full-length die, or my RCBS neck sizing die. I don’t recall sizing the necks, so I can’t say which die it was. Whatever the case, be aware that your sizing dies can have unintended consequences for your brass, like making concentricity much worse, even though they are doing their jobs (sizing).

MEASURING CASE NECK THICKNESS

I mentioned earlier the critical importance of the case neck in determining the accuracy and precision of ammunition. Well, there’s a far more detailed article that can give you better background, and discuss tools for measuring case neck thickness on our sister site, 6mmBR.com. If you aren’t familiar with the concepts you should read this article- it’s a very valuable, and pretty short, overview.

Tools for Measuring Case Necks on 6mmBR.com

I mentioned earlier the critical importance of the case neck in determining the accuracy and precision of ammunition. Well, there’s a far more detailed article that can give you better background, and discuss tools for measuring case neck thickness on our sister site, 6mmBR.com. If you aren’t familiar with the concepts you should read this article- it’s a very valuable, and pretty short, overview.

Tools for Measuring Case Necks on 6mmBR.com

Last edited:

NECK THICKNESS (CHAMBER INDEPENDENT)

By far, and I mean BY FAR, the most painful measurement I’ve taken on the PMC cases was the neck thickness variation. First off I use the RCBS Vernier Ball Micrometer to measure the neck thickness. It’s a good mic and has a positive click when taking measurements. My only complaint is that it’s small and a bit difficult to hold and operate when taking readings. To help things out I made use of a my Dremel bench vice to hold the mic when taking readings.

You: So Slow- why was it such a pain to measure the thickness?

Me: Why my pig-headed-ness of course!

See, I didn’t just measure the neck thickness. I wanted to make sure that I knew 1) how thick the necks were, and 2) how much variation there was in the thickness of each neck. If you just measure the thickness on one point on the neck, there’s a good chance that it’s the middle thickness (on average because there are two of those points on each case between the thinnest and thickest parts of the case neck wall). In other words, there’s a part of the neck that is thicker than that, and a part that is thinner. To address random points of measurement I took readings in 4 places on the neck at 90 degree offsets. To make sure I was consistant I took the first reading adjacent to the “P” in the PMC stamp on the head and always rotated clockwise. In other words, I took readings at the 12:00 (adjacent to the ‘P’), 3:00, 6:00, and 9:00 positions on the case.

It took FOREVER to run through the 150 cases that I measured (600 readings), and it wasn’t just slow- it wasn’t fun. But, the good news is it’s done (for now) and I’ve got results to share! The bad part is these measurements don’t tell us anything about the 12FV- this is case specific data that only matters in describing the PMC brass (which I’ve shared my opinions about). But, here’s the table…

The necks are actually pretty decent- the walls are 0.011” thick on average and vary less than a thousandth- more like ½ a thousandth. The extreme spread strongly supports the standard deviation and is an average of 0.0004”- that means that any case, on average, has a neck thickness that varies by less than ½ a thousandth of an inch.

By far, and I mean BY FAR, the most painful measurement I’ve taken on the PMC cases was the neck thickness variation. First off I use the RCBS Vernier Ball Micrometer to measure the neck thickness. It’s a good mic and has a positive click when taking measurements. My only complaint is that it’s small and a bit difficult to hold and operate when taking readings. To help things out I made use of a my Dremel bench vice to hold the mic when taking readings.

You: So Slow- why was it such a pain to measure the thickness?

Me: Why my pig-headed-ness of course!

See, I didn’t just measure the neck thickness. I wanted to make sure that I knew 1) how thick the necks were, and 2) how much variation there was in the thickness of each neck. If you just measure the thickness on one point on the neck, there’s a good chance that it’s the middle thickness (on average because there are two of those points on each case between the thinnest and thickest parts of the case neck wall). In other words, there’s a part of the neck that is thicker than that, and a part that is thinner. To address random points of measurement I took readings in 4 places on the neck at 90 degree offsets. To make sure I was consistant I took the first reading adjacent to the “P” in the PMC stamp on the head and always rotated clockwise. In other words, I took readings at the 12:00 (adjacent to the ‘P’), 3:00, 6:00, and 9:00 positions on the case.

It took FOREVER to run through the 150 cases that I measured (600 readings), and it wasn’t just slow- it wasn’t fun. But, the good news is it’s done (for now) and I’ve got results to share! The bad part is these measurements don’t tell us anything about the 12FV- this is case specific data that only matters in describing the PMC brass (which I’ve shared my opinions about). But, here’s the table…

The necks are actually pretty decent- the walls are 0.011” thick on average and vary less than a thousandth- more like ½ a thousandth. The extreme spread strongly supports the standard deviation and is an average of 0.0004”- that means that any case, on average, has a neck thickness that varies by less than ½ a thousandth of an inch.

NECK THICKNESS (CHAMBER INDEPENDENT)

By far, and I mean BY FAR, the most painful measurement I’ve taken on the PMC cases was the neck thickness variation. ......... snip................I measured (600 readings), and it wasn’t just slow- it wasn’t fun. ........... snip.............

I can't imagine what you're going to do with that information unless you're trying to get a job as a quality control technician for a brass manufacturing company.

Most serious shooters measure neck thickness with a ball micrometer or something similar. But only a few cases, not 600 readings. I'm tired just reading about it.

Here's what I do. When my primer pockets start getting loose, I get a new batch of Lapua brass. Along with prepping other aspects of the brass, I check the thickness on about 10 rounds or so to establish what the thickness is and how much it varies. Then I neck turn the whole batch, usually 300 rounds. Typically I take a skim cut just deep enough to even out the thickness variations.

I measure the necks of a few turned cases and establish a thickness so that I can select the proper neck bushing, calculate neck tension, etc.

I write that down in my brass log and that's pretty much it.

I'm not in any danger of wearing out my micrometer but you might be .

I'm not sure what to tell ya Mozella...

Let's start with this: I love precision and accuracy in all things. I enjoy getting precise measurements that make things "add up" and make sense. Like I said earlier, I'm wired to dig into the tiniest minutia about things- it's perversely enjoyable for me. I am likely doing a lot more measuring than needed- I'll grant you that. But it's the only way I know to get close to 100% confidence that I understand things (beside being excellent practice for measuring things long term). Maybe later I'll setup some statistical hypothesis to get me 95% confidence intervals for sampling of cases to avoid the extra work, but for now I'll simply rely on brute force measurements and measure just about everything.

I guess in short I have 3 hobbies: 1) shooting my rifles for precision, 2) studying internal ballistics and the drivers of precision, and 3) writing about 1 & 2. If I was simply concerned with shooting small holes, I'd be able to save myself a lot of time on #2 and #3, but I enjoy those hobbies too!

I appreciate the thoughts and input. Your advice and feedback is valuable guidance- keep it coming as I sink my teeth into all the gory details!

Let's start with this: I love precision and accuracy in all things. I enjoy getting precise measurements that make things "add up" and make sense. Like I said earlier, I'm wired to dig into the tiniest minutia about things- it's perversely enjoyable for me. I am likely doing a lot more measuring than needed- I'll grant you that. But it's the only way I know to get close to 100% confidence that I understand things (beside being excellent practice for measuring things long term). Maybe later I'll setup some statistical hypothesis to get me 95% confidence intervals for sampling of cases to avoid the extra work, but for now I'll simply rely on brute force measurements and measure just about everything.

I guess in short I have 3 hobbies: 1) shooting my rifles for precision, 2) studying internal ballistics and the drivers of precision, and 3) writing about 1 & 2. If I was simply concerned with shooting small holes, I'd be able to save myself a lot of time on #2 and #3, but I enjoy those hobbies too!

I appreciate the thoughts and input. Your advice and feedback is valuable guidance- keep it coming as I sink my teeth into all the gory details!

Amen,keep it coming . I am enjoying your thread,you obviously are not afraid to put the work in...much appreciated.I'm not sure what to tell ya Mozella...

Let's start with this: I love precision and accuracy in all things. I enjoy getting precise measurements that make things "add up" and make sense. Like I said earlier, I'm wired to dig into the tiniest minutia about things- it's perversely enjoyable for me. I am likely doing a lot more measuring than needed- I'll grant you that. But it's the only way I know to get close to 100% confidence that I understand things (beside being excellent practice for measuring things long term). Maybe later I'll setup some statistical hypothesis to get me 95% confidence intervals for sampling of cases to avoid the extra work, but for now I'll simply rely on brute force measurements and measure just about everything.

I guess in short I have 3 hobbies: 1) shooting my rifles for precision, 2) studying internal ballistics and the drivers of precision, and 3) writing about 1 & 2. If I was simply concerned with shooting small holes, I'd be able to save myself a lot of time on #2 and #3, but I enjoy those hobbies too!

I appreciate the thoughts and input. Your advice and feedback is valuable guidance- keep it coming as I sink my teeth into all the gory details!

Similar threads

- Replies

- 13

- Views

- 8,041

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.