I use the salt bath method and it works well for me. I don't think I could mess up as compared to the torch and pan of water method. I can clearly tell an improvement in the "workability" of the brass.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Salt Bath Annealing - AMP Study

- Thread starter MikeMcCasland

- Start date

This seems entirely reasonable to me. I think people would be surprised by how bad thier annealing techniques are when put under a microscope. This is one reason (of several) that I don't do it. The time/temperature/hardness relationship for small thin samples for very short times is very hard to nail down. You won't find any literature on it. I've tried. It's not out there publicly.

As for bagging on competitor, I'm not sure who that competitor would be. They're just saying why their machine is better than a salt bath. Again, totally reasonable. (Note the part at the end that says, in effect, "If you can't afford ours, buy a torch based competitor's. Just don't play around with salt baths." Hardly a cynical jab at business rivals.)

If one is to anneal, I honestly can't see a reason for not using an AMP to anneal, other than the hefty price tag. They're literally the only product on the market who has tested and published their results, and it does exactly what they says it does. There are plenty of reasons to believe that torches and salt/lead baths would create inconsistent results.

Whether or not you need that level of precision is an entirely different discussion. The main critique of their machine in my opinion is that their target annealed state is totally arbitrary. If a torch and a drill does what you want, that's all you need. If you want repeatable hardness, nobody has stepped up to challenge AMP.

I've got no dog in this fight. I don't own their machine (or anyone else's), and I have no intention of buying one.

Edit: The interesting thing here is that I can't think of what the mechanism would be that would prevent the neck from annealing while allowing the rest of the case to. Perhaps its corrosion or some sort of chemical reaction that insulates the neck as it heats quickly, where as the rest of the case avoids that. Just speculating. It's an interesting phenomenon. A head scratcher. I suspect it has something to do with the rate of heat transfer into the case.

Where did the information come from that the body is softer than the neck after annealing. Doesn't make sense. I think it was AMPS that published a lot of icro hardess data after annealing. Without reviewing I am sure the necks were softer.

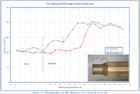

Chart from the AMPS website.

dcali

Bullet Maker

Read the article in the op. They discovered that even with a lengthy time (20 seconds) at 550 degrees, they could not get the neck to anneal, while the rest of the case softened significantly. I agree, this is hard to figure out. But it’s what they’re claiming.Where did the information come from that the body is softer than the neck after annealing. Doesn't make sense. I think it was AMPS that published a lot of icro hardess data after annealing. Without reviewing I am sure the necks were softer.

Chart from the AMPS website.

View attachment 1107079

rwj

Gold $$ Contributor

Read the article in the op. They discovered that even with a lengthy time (20 seconds) at 550 degrees, they could not get the neck to anneal, while the rest of the case softened significantly. I agree, this is hard to figure out. But it’s what they’re claiming.

Having now read the AMP paper, I wonder why they didn’t include a hardness/position profile for cases processed via their induction machine like the one posted above by @Webster? If the two plots in Figure 3.5 are for the same case before and after annealing, it appears that AMP’s program 43 has a small effect on neck hardness too. I’ve always wondered how much case neck annealing occurs during the firing process?

I think heat soak from the body of the case skews the results as demonstrated by AMP.

I think the beauty of inductive annealing is that the annealing process does not depend on heat transfer from the surface. That alone, at least from a technical viewpoint, is a superior method. Is it really required? I don't know but if you are happy with your current technique, then more power to you.

I think the beauty of inductive annealing is that the annealing process does not depend on heat transfer from the surface. That alone, at least from a technical viewpoint, is a superior method. Is it really required? I don't know but if you are happy with your current technique, then more power to you.

Last edited:

Read the article in the op. They discovered that even with a lengthy time (20 seconds) at 550 degrees, they could not get the neck to anneal, while the rest of the case softened significantly. I agree, this is hard to figure out. But it’s what they’re claiming.

Just read the article. It doesn't make sense. Contradicts all other peoples accurate data. That's 550C not 550F for 20 seconds and the neck isn't annealed??? Look at my charts put on the website on 17 May. They are saying that about 1100F for 20 seconds in salt doesn't anneal.

dcali

Bullet Maker

Well they’re saying it does, but not the neck. Why that would be is beyond me, but I wouldn’t rule out that what they’re seeing is possible. Sometimes weird stuff happens. It could also be testing errors I suppose. Hard to say without their input.Just read the article. It doesn't make sense. Contradicts all other peoples accurate data. That's 550C not 550F for 20 seconds and the neck isn't annealed??? Look at my charts put on the website on 17 May. They are saying that about 1100F for 20 seconds in salt doesn't anneal.

MikeMcCasland

Team Texas F-T/R

Just read the article. It doesn't make sense. Contradicts all other peoples accurate data. That's 550C not 550F for 20 seconds and the neck isn't annealed??? Look at my charts put on the website on 17 May. They are saying that about 1100F for 20 seconds in salt doesn't anneal.

I think they're saying they couldn't get it properly annealed.

Properly annealed in this context would indicate a hardness around ~95-100HV. It looks like they were only able to achieve ~120HV, and in doing so destroyed the body of the case.

Ever heard of the skin effect?I think heat soak from the body of the case skews the results as demonstrated by AMP.

I think the beauty of inductive annealing is that the annealing process does not depend on heat transfer from the surface. That alone, at least from a technical viewpoint, is a superior method. Is it really required? I don't know but if you are happy with your current technique, then more power to you.

Ever heard of the skin effect?

I'm tired of reading non-sense.

You don't like physics? Skin effect is a well known result of time varying currents on conductors. Induction heating quite often only heats the surface.I'm tired of reading non-sense.

Last edited:

You don't like physics? Skin effect is a well known result of time varying currents on conductors. Induction heating quite often only heats the surface.

No heat treater considers skin affect. Have done a lot of heat treating. You guys have to quit making stuff up.

At 550C you might just start annealing some already annealed brass with only mild cold work. And as I’ve previously said, hardness is only an indicator of annealing. For definitive proof you have to look at the microstructure. Don’t forget that at low residual cold work annealing takes a higher temperature and more time. So you have to know the condition of the brass going in. If you don’t have enough cold work you’re only stress relieving and the hardness change is a lot smaller.

Just read the article. It doesn't make sense. Contradicts all other peoples accurate data. That's 550C not 550F for 20 seconds and the neck isn't annealed??? Look at my charts put on the website on 17 May. They are saying that about 1100F for 20 seconds in salt doesn't anneal.

The graphs YOU posted in the 4th post explain it all. the hardness curves are all different based on the amount of cold work.

Oh, really. Again, you don't believe in actual physics?No heat treater considers skin affect. Have done a lot of heat treating. You guys have to quit making stuff up.

https://www.asminternational.org/do...yNow.pdf/917605db-7173-4333-80d0-609dfc9ef8cf

Here's a selected quote from the above paper

The skin effect must be clearly understood because it affects all of the most critical characteristics of an induction system. According to a commonly accepted definition of the skin effect, approximately 86% of all power induced by an induction coil will be concentrated in the surface layer (the “skin”). This layer is called the reference depth or current penetration depth and is typically designated by the symbol d. The skin effect is considered as a fundamental property of any process that relies on heating by electromagnetic induction.

More "made up" stuff

https://en.wikipedia.org/wiki/Skin_effect

https://inis.iaea.org/collection/NCLCollectionStore/_Public/38/085/38085419.pdf?r=1&r=1

https://www.sms-elotherm.com/wp-content/uploads/2018/05/hp_4_2015_04_FB_Dappen.pdf

https://inductoheat.com/induction-heating/

Just some internet fairy tale I suppose.

I would guess that annealer operates in the kHz range. Skin depth of copper at 10 kHz is <1 mm. Most likely, it's really only heating the surface of the brass.

Ever heard of the skin effect?

Yes. I am well familiar with the phenomenon in my trade. Given that a cartridge case is tubular in construction and not like a solid core or multi stand cable, skin effect is of no consequence in this scenario. The cartridge case is not being used as an active current carrying device anyway so skin effect is of no relevance.

Oh, really. Again, you don't believe in actual physics?

https://www.asminternational.org/do...yNow.pdf/917605db-7173-4333-80d0-609dfc9ef8cf

Here's a selected quote from the above paper

More "made up" stuff

https://en.wikipedia.org/wiki/Skin_effect

https://inis.iaea.org/collection/NCLCollectionStore/_Public/38/085/38085419.pdf?r=1&r=1

https://www.sms-elotherm.com/wp-content/uploads/2018/05/hp_4_2015_04_FB_Dappen.pdf

https://inductoheat.com/induction-heating/

Just some internet fairy tale I suppose.

I would guess that annealer operates in the kHz range. Skin depth of copper at 10 kHz is <1 mm. Most likely, it's really only heating the surface of the brass.

Are you in IT?

How about this one?

https://fluxtrol.com/inc/pdf/Design-and-Fab-of-Inductors-for-HT.pdf

How about this one?

https://fluxtrol.com/inc/pdf/Design-and-Fab-of-Inductors-for-HT.pdf

Oh, really. Again, you don't believe in actual physics?

https://www.asminternational.org/do...yNow.pdf/917605db-7173-4333-80d0-609dfc9ef8cf

Here's a selected quote from the above paper

More "made up" stuff

https://en.wikipedia.org/wiki/Skin_effect

https://inis.iaea.org/collection/NCLCollectionStore/_Public/38/085/38085419.pdf?r=1&r=1

https://www.sms-elotherm.com/wp-content/uploads/2018/05/hp_4_2015_04_FB_Dappen.pdf

https://inductoheat.com/induction-heating/

Just some internet fairy tale I suppose.

I would guess that annealer operates in the kHz range. Skin depth of copper at 10 kHz is <1 mm. Most likely, it's really only heating the surface of the brass.

A quote from the last paper you have listed there

Unlike some combustion methods, induction heating is highly controllable regardless of batch size. Varying the current, voltage, and frequency through an induction coil results in fine-tuned engineered heating, perfect for applications like hardening and tempering, stress relieving, annealing and other forms of heat treating. A high level of precision is essential for critical industries like automotive, aerospace, the military, off-road machinery and oil and gas, just to name of few. The advantages of induction heating can be seen in such applications as fiber-optics, bonding, wire hardening, tempering, brazing, soldering, sealing, coating, etc. Induction heating is well suited for specialty metal applications involving titanium, precious metals, and some advanced composites. The precise heating control available with induction is unmatched.

I am not quite sure which side of the argument you are on.

Having built several machines myself and played with all of the variables. I have found induction heating is certainly suited to Brass Case annealing. Any skin effect is just not applicable in the range that the induction machines operate.

Skin effect is more of a consideration of inductor coil design rather than what we are dealing with in this case, being the heating of the cartridge case neck and perhaps some of the shoulder. Eddy currents (Foucault currents for the pedantic) induced in the case neck is what is creating the heating effect. That is consistent enough for our purposes here if the induction heating device is properly designed.

Similar threads

- Replies

- 39

- Views

- 1,482

- Replies

- 50

- Views

- 6,647

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.