AlNyhus

Silver $$ Contributor

Do the Mack Bros replacement bolts nee to be fitted to action for proper primary extraction?

Distance from locking lug to handle

Remington 700 SA Bolt Upgrade | Mack Brothers

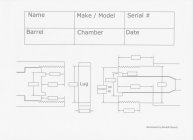

Complete and fully assembled Remington 700 SA Bolt Upgrade. Bolt bodies are nitrided to maintain strength and durability while still allowing smooth bolt