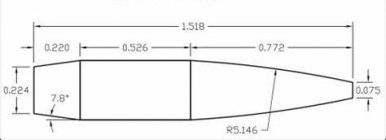

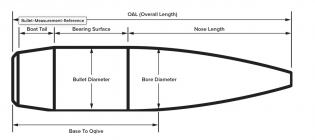

For instance, a 180gr Hybrid. Boat Tail is .245 and Bearing Surface is .430, but BTO is .768. What accounts for the other .093?

Berger is providing you a length from the back of the bullet to the .277 bore diameter datum on the ogive.

It is a legitimate dimension in terms of manufacturing and inspection, but it does not necessarily tell you where the bullet first intercepts the leade. More directly related to your question, it does not tell you where the bearing surface meets the ogive.

Part of your missing .093 is the axial length from the end of the bearing surface, forward to the .277 diameter on the bullet ogive. But it is not all of the missing .093. Looking closely at the diagram on the

Berger page, they do not include the radiused heel in the boat tail length, so some of the missing .093 is that radius and some is the axial length between the .277 and the tangent point or junction of the bearing surface to ogive.

Where the bullet actually first "touches" the leade is between bullet diameter and bore diameter. In a 1.5 degree leade, most modern spitzer type bullets will first intercept the leade near full bullet diameter. It varies from bullet to bullet. The variance has to do with the ogive curvature in the engraving zone. I have measured the intercept diameter anywhere from .0003 under to .002x under bullet diameter and anywhere in between. (Intercept = where it is first going to just touch. Using tools like the Hornady comparator or the Sinclair method, you will easily push the bullet well past this point with even the lightest touch. They are still useful and repeatable tools, but they are giving you a measurement that is farther out than the true intercept).

Change the leade angle and the intercept diameter will change. Change the ogive curvature in the zone that will be engraved by the lands, and the intercept diameter will change. It will vary a little bit from lot to lot and certainly from one set of bullet forming dies to the next. It is not necessarily important to know the exact intercept diameter to 4 decimals. But it can help you understand the relationship of the bullet to leade.

Because the intercept diameter is larger than the bore diameter, it will be somewhat farther back on the ogive than dimensioned on Berger's chart. For example, lets say* the intercept diameter is .283 on the 180 Hybrid. The standard 7mm bore diameter is .277. We have to move backward along the ogive from .277 diameter to .283 diameter to arrive at the Base to Intercept.

*.283 was used only as an example, I don't know off the top of my head what the intercept diameter is for the 180 Hybrid, .001 under bullet diameter is as good a rule of thumb as any.