You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Polishing the inside of necks on new brass

- Thread starter LVLAaron

- Start date

Am I missing something here?

Primed brass.

Isn't whatever is coming off the inside of the neck or the brush, or sandpaper, or whatever going to get into the primer cup opening at the base of the case?

Primed brass.

Isn't whatever is coming off the inside of the neck or the brush, or sandpaper, or whatever going to get into the primer cup opening at the base of the case?

LVLAaron

Gold $$ Contributor

Do you have any idea of the case life and capacity compared to Lapua 223?

Havent reloaded them yet. They're so cheap, If you only get one reload on them they're still a great choice. They're 12 cents each, primed.

LVLAaron

Gold $$ Contributor

Dont sweat it. If it werent already primed Id just wet tumble them for an hour and theyd be perfectly fineDang. Something else to do during brass prep....

Dont sweat it. If it werent already primed Id just wet tumble them for an hour and theyd be perfectly fine

It's hard to argue at $0.10/case ($100 for 1000 cases after backing out $25'ish of primer value). It the first time I've seen virgin brass that is sold primed that wasn't a batch of pull-down surplus. Steel pin tumbling was the easy answer, except for wasting good primers and then having to reprime the cases.

God knows I have done more work for less reason or value... I keep picking up brass and tumbling it to then ship it off to friends for no better reason then it was there and so was I.

Good luck...make sure the Advil jar is full.

Last edited:

I thank you for this I ordered my diamond hone today

LVLAaron

Gold $$ Contributor

I did end up getting some small dingle-ball hones. Even the finest grade are too aggressive for brass necks.

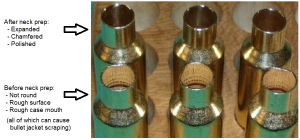

Ultimately, some 00 steel wool woven into a nylon brush in a slow speed drill did the trick.

I followed up with a coating of Neolube #2 inside the necks and they are exactly how I like them.

Ultimately, some 00 steel wool woven into a nylon brush in a slow speed drill did the trick.

I followed up with a coating of Neolube #2 inside the necks and they are exactly how I like them.

joshb

Gold $$ Contributor

Maybe it’s acting like more neck tension?Rub a piece of glass flat on another piece then put sand between them and try it. Polished surfaces together have too much surface tension thus friction

memilanuk

Gold $$ Contributor

I did end up getting some small dingle-ball hones. Even the finest grade are too aggressive for brass necks.

Ultimately, some 00 steel wool woven into a nylon brush in a slow speed drill did the trick.

I followed up with a coating of Neolube #2 inside the necks and they are exactly how I like them.

I was wondering about that. I saw the 'extra fine' was listed as 800 grit, which seemed a little bit coarse to me.

I'd used steel wool on a bronze brush in the past, but as you'd mentioned previously, it's a bit messy and somewhat consumable - you have to stay on top of it to get a consistent finish. Got curious about the mention of VFG pellets, as I have some of those around from previous adventures chasing carbon in a particular barrel

Do you do it to your regular match brass, or just that pre-primed Wolf stuff you had a pile of?

LVLAaron

Gold $$ Contributor

I was wondering about that. I saw the 'extra fine' was listed as 800 grit, which seemed a little bit coarse to me.

I'd used steel wool on a bronze brush in the past, but as you'd mentioned previously, it's a bit messy and somewhat consumable - you have to stay on top of it to get a consistent finish. Got curious about the mention of VFG pellets, as I have some of those around from previous adventures chasing carbon in a particular barrel

Do you do it to your regular match brass, or just that pre-primed Wolf stuff you had a pile of?

Just the primed wolf stuff. It has some kind of gunk on the necks, maybe it's the tar or whatever they use on factory ammo to seal them up, don't know, but it really made for inconsistent seating pressure.

My "normal" brass, I just tumble, add neolube, mandrel the neck, and seat.

jepp2

Gold $$ Contributor

I tied using that type hone for honing my FL sizing dies to increase the neck diameter. My single try failed as the balls lost their grit too fast. I wound up getting the hones from MSC. They work fine, but using lapping compound in the case neck of brass prior to loading not a good idea. I did see this in a thread a while back, impressed me. However on new brass I always chamfer the inside sharp edge and use Imperial to coat the case neck until I have carbon.I did end up getting some small dingle-ball hones. Even the finest grade are too aggressive for brass necks.

LVLAaron

Gold $$ Contributor

I have encountered the Eastern Block tar/sealant. My solution has been to dip a Q-in acetone and wipe it away.

Doh! - I love acetone. I have it all over the shop I dont know why I didn't think of that. I still have 2k boxed up... next time I need some I'll try that!

Similar threads

- Replies

- 4

- Views

- 1,261

- Replies

- 54

- Views

- 2,532

- Replies

- 30

- Views

- 4,230

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.