fatelvis

Silver $$ Contributor

Best today is a borescope. Just look. Otherwise... I dunno without removing and doing every every step as carefully as possible to assure it's correct.

One note as you start looking for every minor flaw, is that — unlike at the gas key — at the gas block minor blowby is NBD. Alignment matters but there's no gasket etc because it doesn't matter up there.

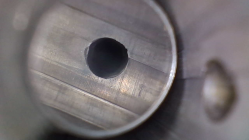

Here are two pics of the gas port. It’s hard to see into the hole and see if it’s aligned.

Attachments

Last edited: