DLT

Silver $$ Contributor

I can feel it with my mandrel or the Lee collet die. If it’s not a tight neck chamber you can tell with a simple bullet drop. I don’t have any tight neck chambersI’m not sure that’s 100% accurate

That could be a neck thickness to chamber neck issue.

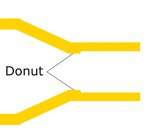

If bullets drop almost all the way down the neck but get stopped or resistance at the neck/shoulder junction that would be a sign of donuts.

You really feel it when seating Bullets.

As the shank of the bullets gets to the donut a distinct increase in resistance is felt.

If your shank stops forward of the donut the donut is irrelevant